Quick-change slips hydraulic rubber cylinder chuck

A technology of rubber cartridges and chucks, which is applied to drilling equipment, earthwork drilling, drill pipes, etc., can solve the problems of shortening the service life of rubber cartridges and increasing production costs, so as to ensure coordination of actions, improve efficiency, and lower cracking pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

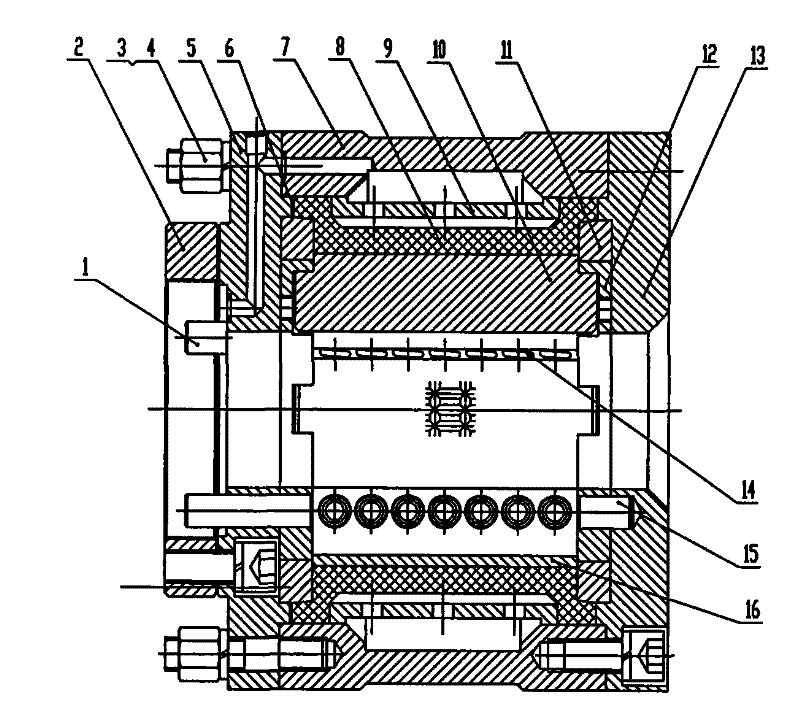

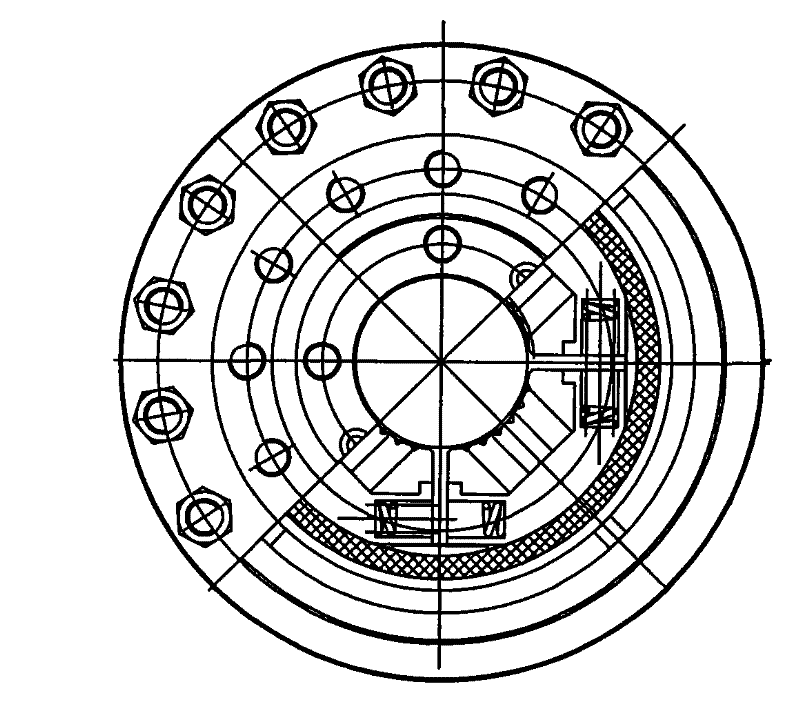

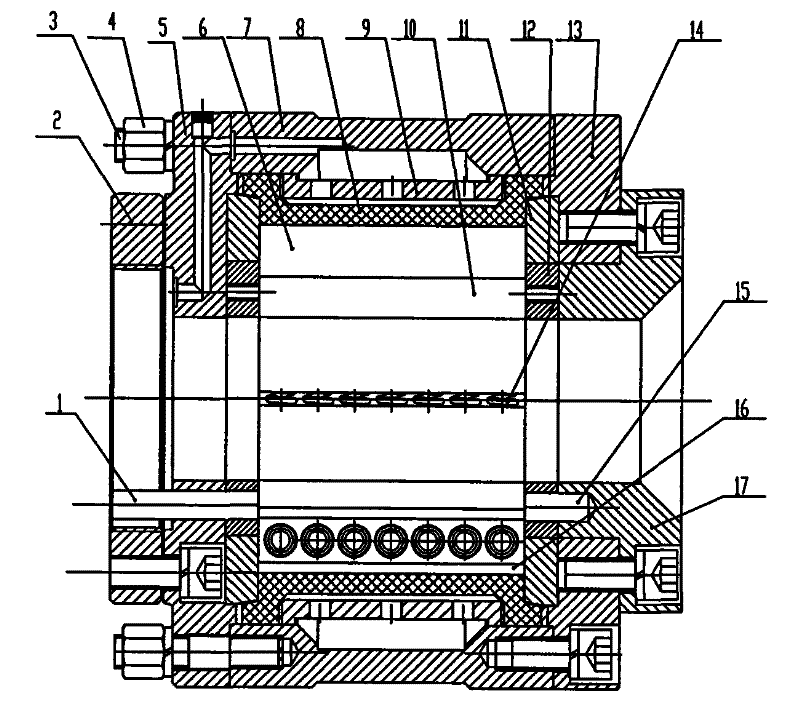

[0017] See figure 1 , figure 2 , The present invention adds a slip seat 6 and an end gland 17 on the basis of the hydraulic rubber cartridge chuck. When replacing slips of different specifications and sizes, remove the end gland 17 and take out the old slips and replace Install the new slip and install the upper end gland 17.

[0018] See figure 2 , image 3 , The quick-change slip hydraulic rubber cartridge chuck of the present invention includes a long pin 1, a pull plate 2, a stud bolt 3, a nut 4, a back cover 5, a slip seat 6, a chuck body 7, a rubber cartridge 8, The supporting ring 9, the slip 10, the end pressure ring 11, the torque transmission plate 12, the front cover 13, the spring 14, the short pin 15, the backing plate 16, and the end pressure cover 17 are composed of parts. The transfer plate 2, the rear cover 5, the chuck body 7, the rubber cylinder 8, the support ring 9, the end pressure ring 11, the front cover 13 and the backing plate 16 form a unilateral flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com