Electromagnetic method pipe fitting shaping technique

A technology of electromagnetic method and pipe fittings, applied in wellbore/well components, earthwork drilling, etc., can solve problems such as difficulty in controlling explosion shaping repair method, and achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

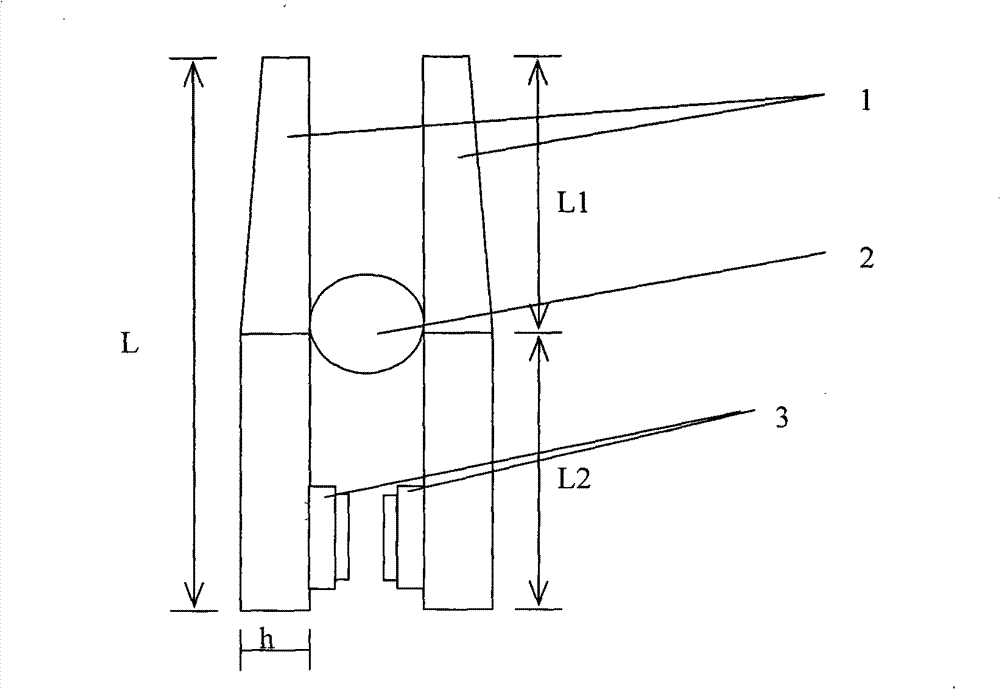

Embodiment 1

[0022] In this embodiment, the length of the shaper working rod is 800mm, the one-sided taper angle is 1.2 degrees, the lengths of the L1 and L2 sections are respectively 300mm and 500mm, and the bottom thickness h is 30mm. The working rod gap is 62mm; the gap d is 21mm. After being installed, it is placed in a flat tube with an original inner diameter of 130 mm and a thickness of 3 mm, and a continuous current is applied to the shaper coil (3), and the flat tube slowly expands and returns to its original shape under the action of electromagnetic force.

Embodiment 2

[0024] In this embodiment, the length of the shaper working rod is 800mm, the one-sided taper angle is 1.2 degrees, the lengths of the L1 and L2 sections are respectively 300mm and 500mm, and the bottom thickness h is 30mm. The working rod gap is 62mm; the gap d is 21mm. After being installed, it is placed in a flat tube with an original inner diameter of 130 mm and a thickness of 8 mm, pulse current is applied to the shaper coil (3), and the flat tube is rapidly expanded and restored to its original shape under the action of electromagnetic force.

Embodiment 3

[0026] In this embodiment, the length of the shaper working rod is 800mm, the one-sided taper angle is 1.5 degrees, the lengths of the L1 and L2 sections are respectively 300mm and 500mm, and the bottom thickness h is 30mm. The working rod gap is 62mm; the gap d is 25mm. After installation, it is placed in a flat tube with an original inner diameter of 130 mm and a thickness of 2 mm, and a continuous current is applied to the shaper coil (3), and the flat tube is slowly expanded and restored to its original shape under the action of electromagnetic force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com