Thermal-prestressed fusion casing for heavy-oil thermal recovery process, and using method thereof

A heavy oil thermal recovery, oil-casing technology, which is applied in the direction of casing, drilling pipe, production fluid, etc., can solve the problems of not considering the radial load of the casing, not being able to take advantage of the technology, and the thermal elongation limit of the casing, etc. , to achieve the effect of simple structure, integrity protection and thermal stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

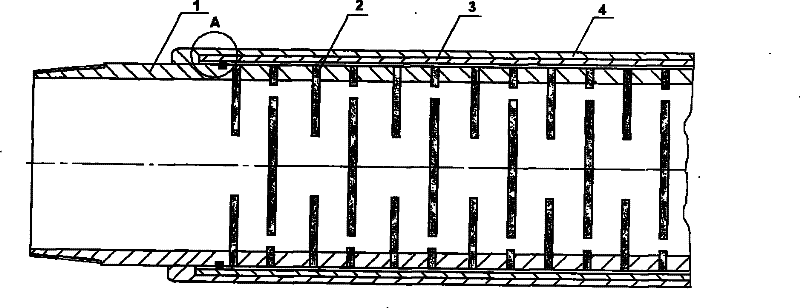

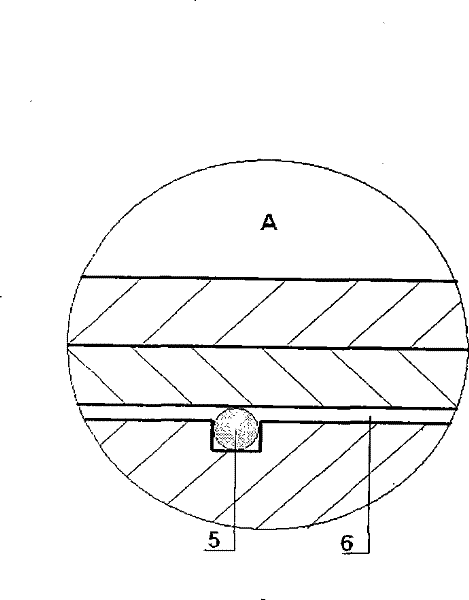

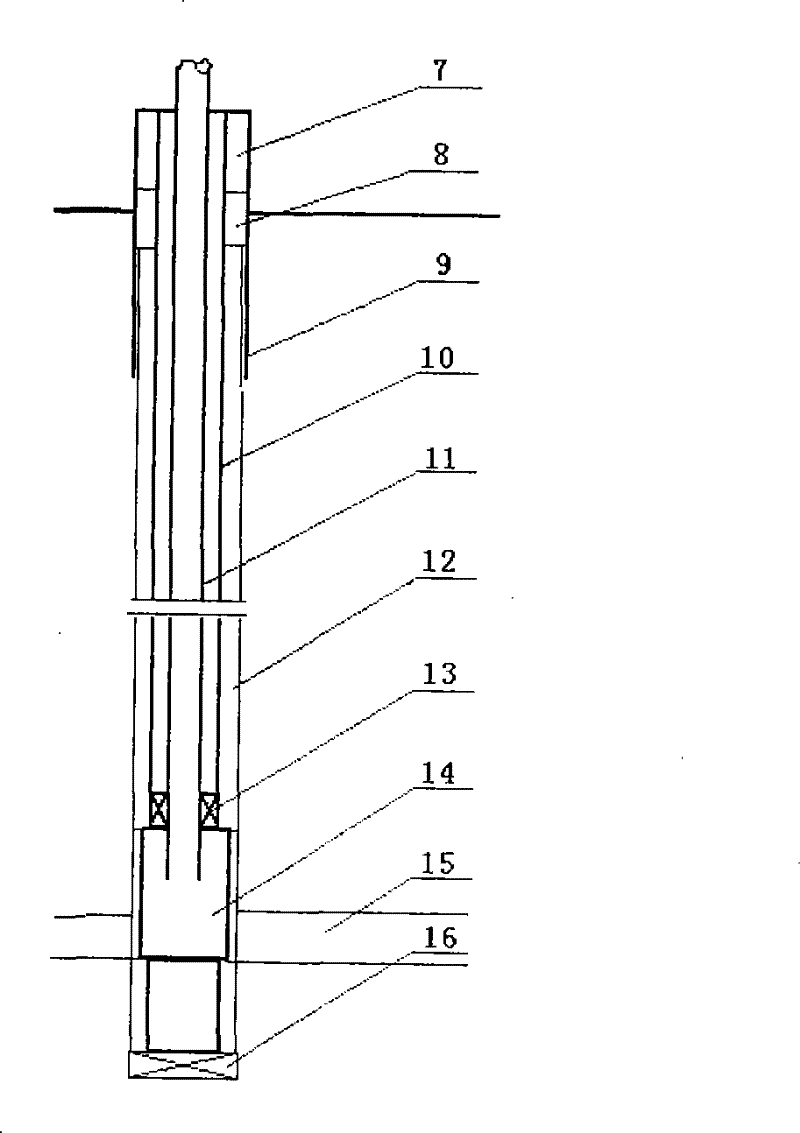

[0022] This embodiment is a 7" heat-prestressed fusion pipe, which uses API standard (American Petroleum Industry Association standard) 10m long 7" oil casing as a processing blank, including oil casing 1, steel sheath 3, and winding pipe 4. Among them, the two ends of the oil casing 1 leave the distance for the installation of the coupling to process a sealing groove, and the sealing groove is embedded with a high-temperature sealing ring 5, which is used for the internal and external isolation of the oil casing in the cementing process; 1 A number of slits 2 are distributed between the sealing grooves at both ends, and filled with filling material with temperature characteristics of 100°C thermal deformation and 300°C thermal rheology. A steel sheath 3 is sheathed on the outer surface of the oil casing 1, and a winding tube 4 is arranged on the outer surface of the steel sheath, and the steel sheath 3 is axially fixed by the winding tube. During the specific implementation p...

Embodiment 2

[0025] This embodiment is a 7" heat-prestressed fusion pipe, which uses API standard (American Petroleum Industry Association standard) 10m long 7" oil casing as a processing blank, including oil casing 1, steel sheath 3, and winding pipe 4. Among them, the two ends of the oil casing 1 leave the distance for the installation of the coupling to process a sealing groove, and the sealing groove is embedded with a high-temperature sealing ring 5, which is used for the internal and external isolation of the oil casing in the cementing process; 1 A number of slits 2 are distributed between the sealing grooves at both ends, and filled with filling material with temperature characteristics of 100°C thermal deformation and 300°C thermal rheology. A steel sheath 3 is sheathed on the outer surface of the oil casing 1, and a winding tube 4 is arranged on the outer surface of the steel sheath, and the steel sheath 3 is axially fixed by the winding tube. During the specific implementation p...

Embodiment 3

[0028] This embodiment is a 7" heat-prestressed fusion pipe, which uses API standard (American Petroleum Industry Association standard) 10m long 7" oil casing as a processing blank, including oil casing 1, steel sheath 3, and winding pipe 4. Among them, the two ends of the oil casing 1 leave the distance for the installation of the coupling to process a sealing groove, and the sealing groove is embedded with a high-temperature sealing ring 5, which is used for the internal and external isolation of the oil casing in the cementing process; 1 A number of slits 2 are distributed between the sealing grooves at both ends, and filled with filling material with temperature characteristics of 100°C thermal deformation and 300°C thermal rheology. A steel sheath 3 is sheathed on the outer surface of the oil casing 1, and a winding pipe 4 is arranged on the outer surface of the steel sheath 3, and the steel sheath 3 is axially fixed by the winding pipe 4. During the specific implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com