Damping type self-regulating boundary gland seal

A steam seal ring, a new type of technology, applied in the field of blade top steam seal, shaft seal and diaphragm steam seal, can solve the problems of large dynamic and static gap, gas leakage, poor carbon tooth strength, etc., to achieve good sealing effect and strong sealing effect. Damping effect, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

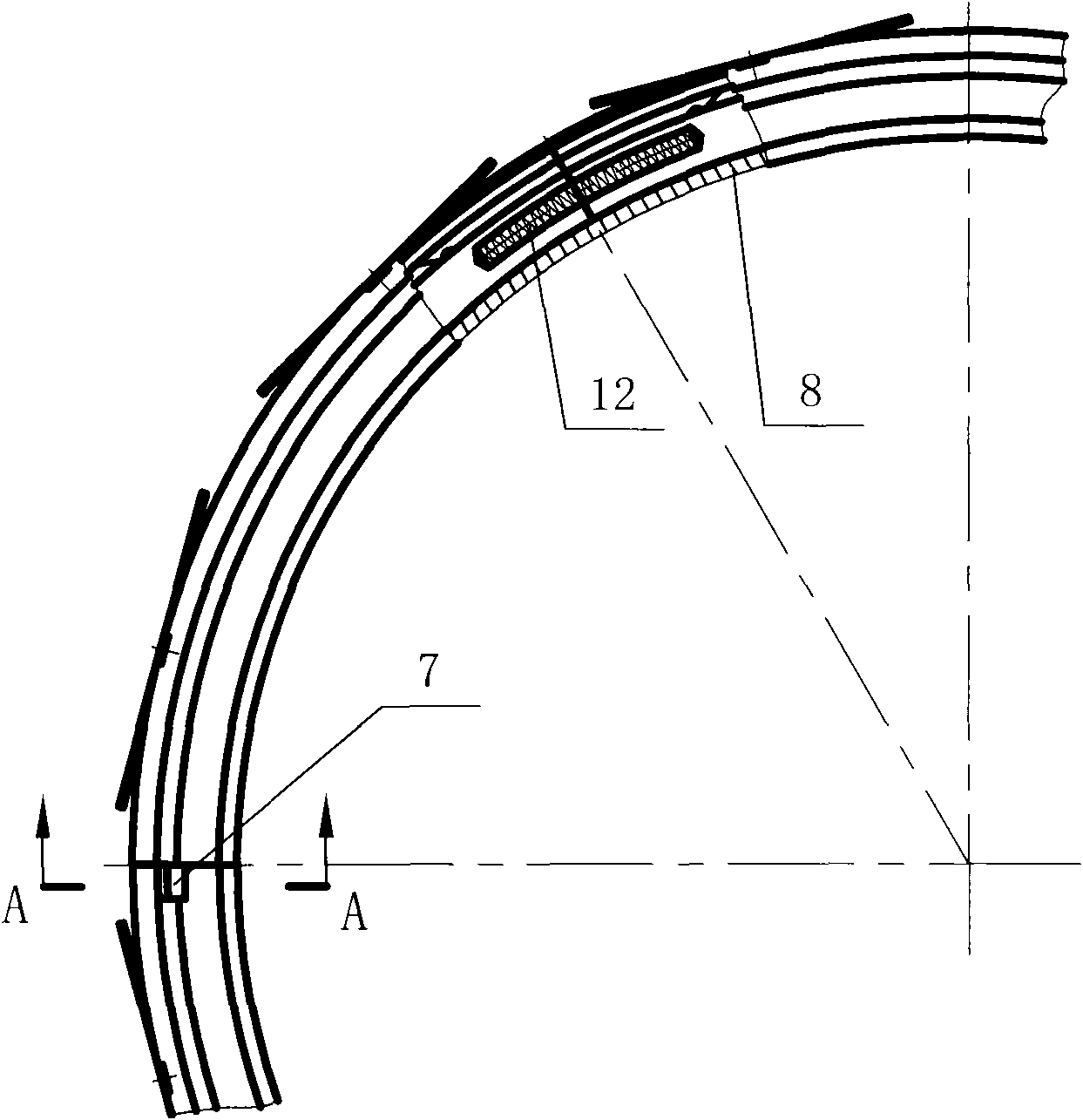

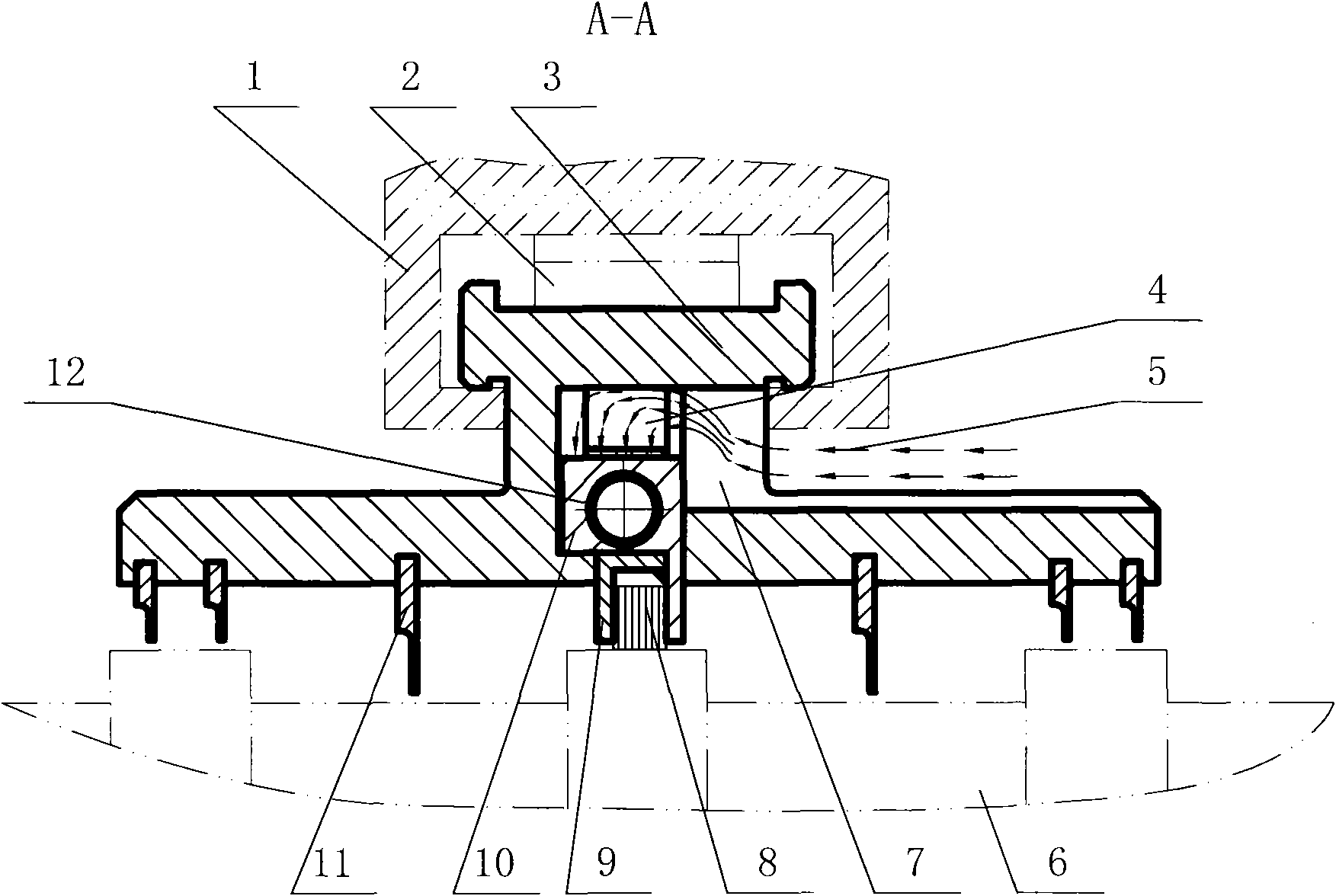

[0014] The present invention is composed of a cylinder block 1, a plate spring 2, a new seal ring 3, a high-temperature sheet spring 4, a high-temperature, high-pressure gas 5, a rotating shaft 6, a steam inlet chamber 7, a thin metal wire 8, a pressure ring 9, a slide plate 10, It consists of ferrite labyrinth teeth 11 and high temperature coil spring 12. It is characterized in that the cross-section of the multi-divided new seal ring 3 is made into a T-tail shape, and after adding a plate spring 2 on the back, it slides into the existing T-tail groove of the cylinder block 1 to form a first-stage floating. After loading onto the high-temperature thin leaf spring 4 on the back of the slide plate 10 of multiple equal parts again, cooperate in the inner groove of the novel seal ring 3, and reserve a cavity on the whole garden circumference of the slide plate 10 back, and make this cavity It communicates with the steam inlet chamber 7. Slide plate 10 is under the effect of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com