Natural gas hydrogen production HCNG engine gas supply system

A gas supply system and engine technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of changing, occupying space, and inability to carry out fuel quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

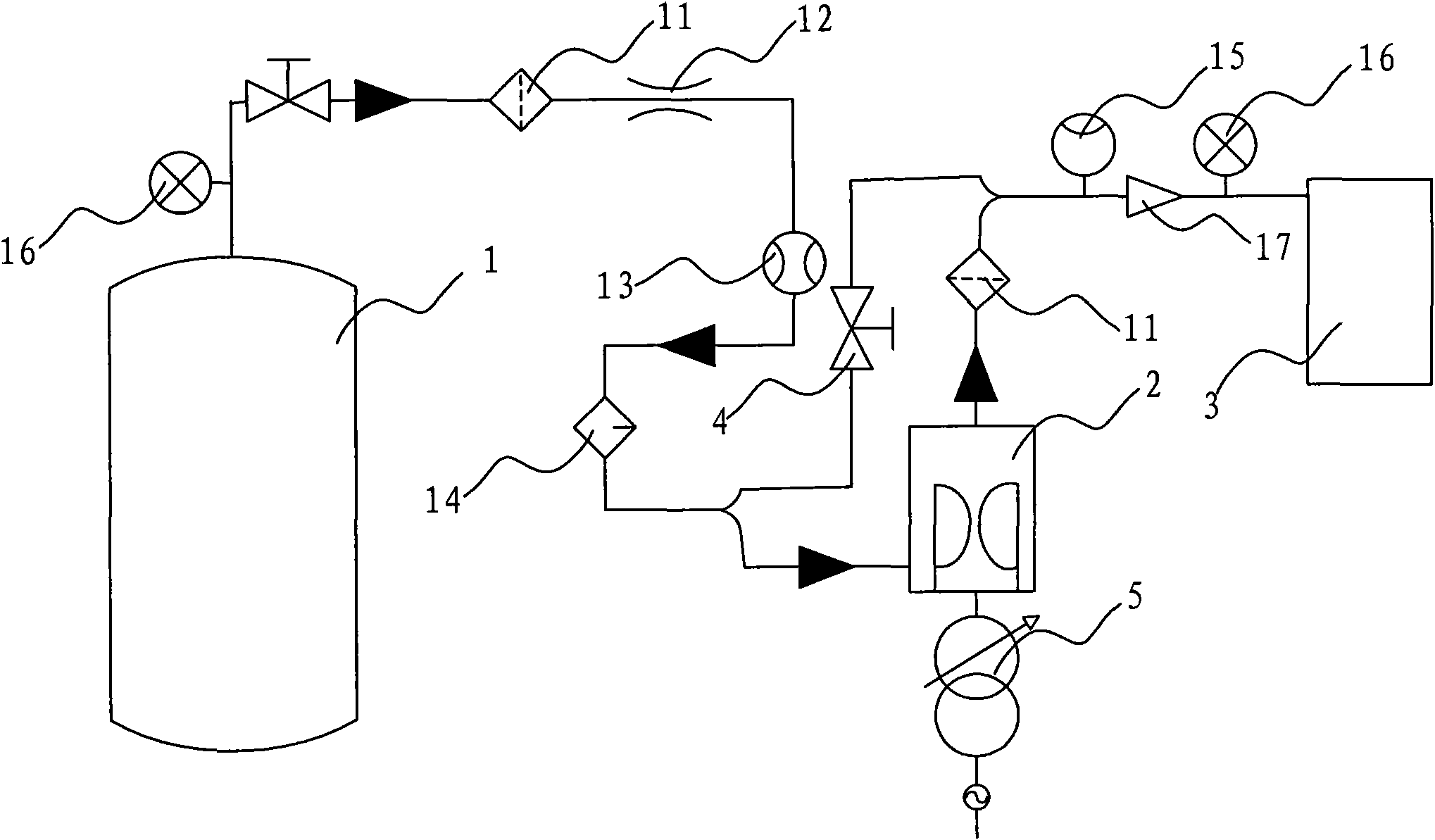

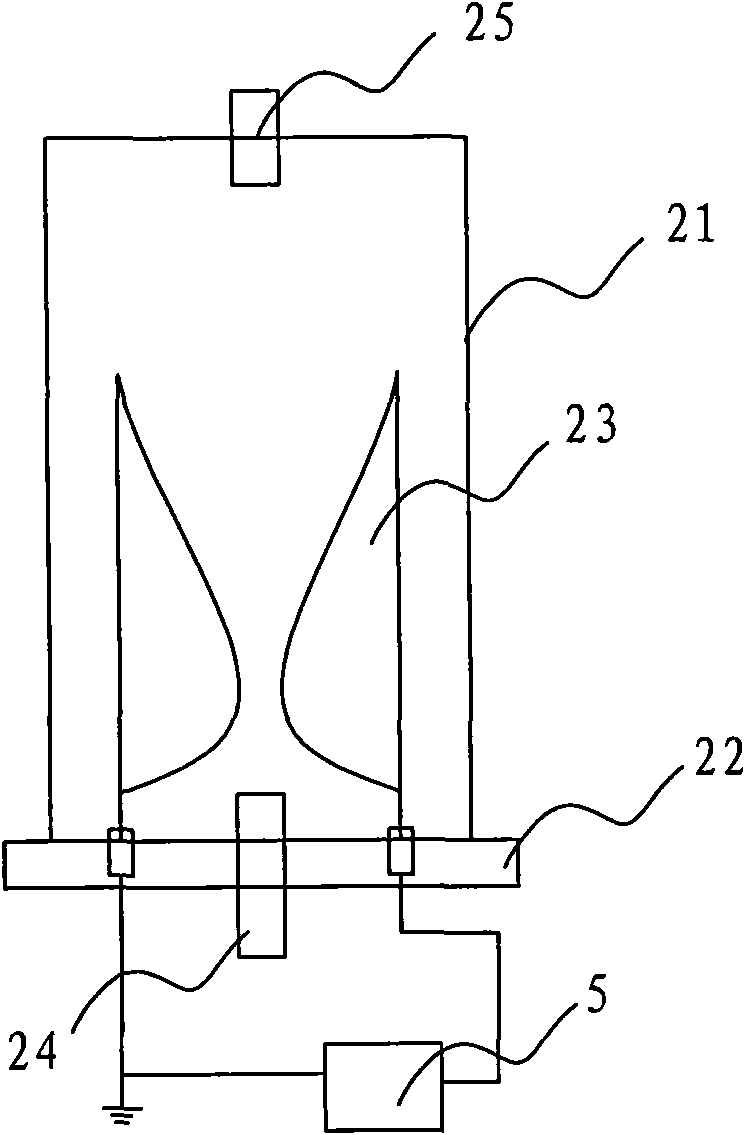

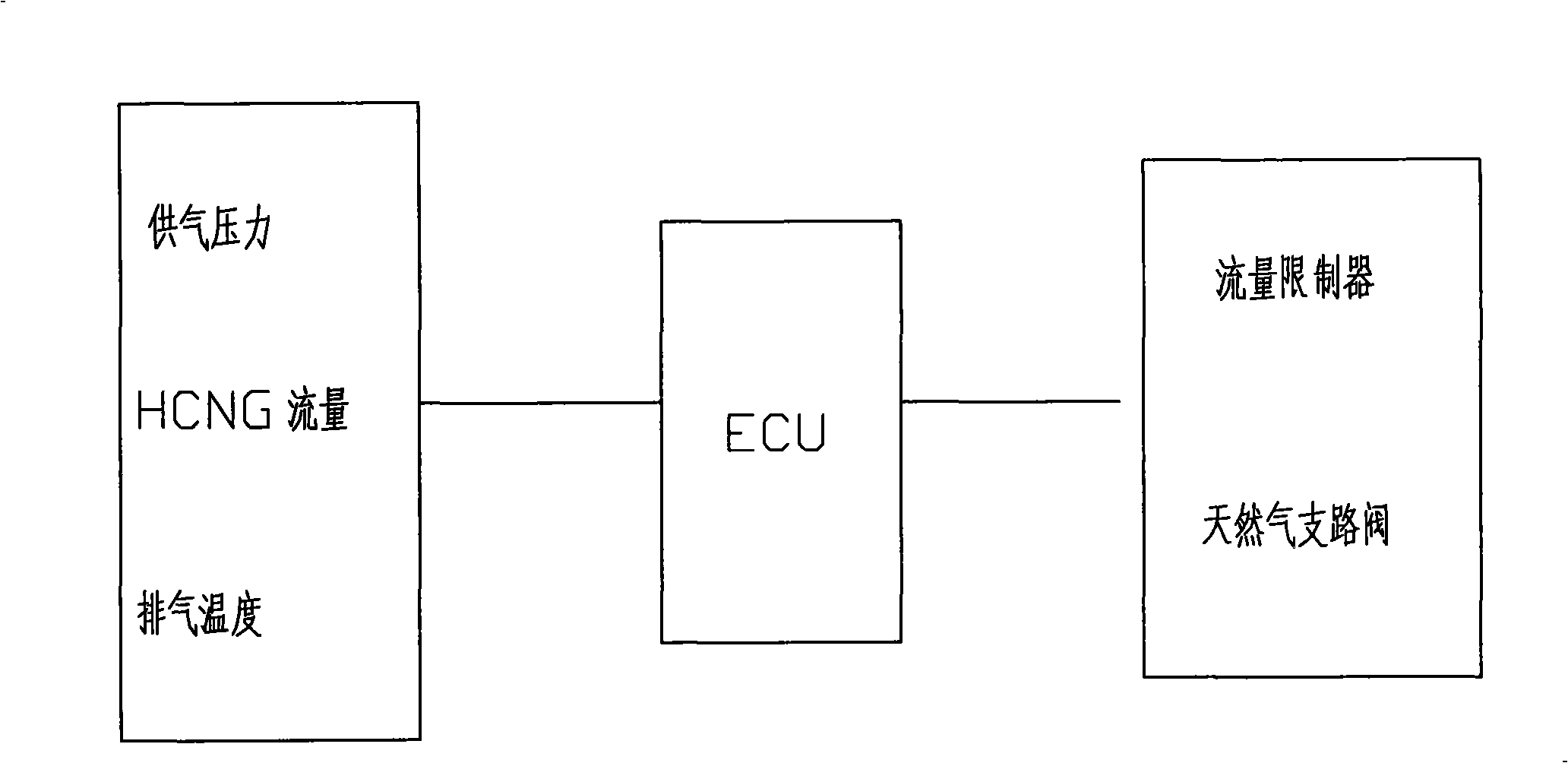

[0016] Such as figure 1 The gas supply system shown mainly includes a natural gas cylinder 1 , a gas pipeline and an engine 3 . The natural gas cylinder 1 communicates with the engine 3 through a gas pipeline, and part of the gas pipeline is connected in parallel with a hydrogen production branch. The gas pipeline before the hydrogen production branch starts from the gas outlet of the steel cylinder and passes through the filter 11a, the flow restrictor 12, the flow meter 13 and the dryer 14 in sequence. The hydrogen production branch is connected with a sliding arc reactor 2 and a filter 11b. There is a valve 4 on the gas pipeline parallel to the hydrogen production branch, which cooperates with the flow limiter 12 to control the ratio of the mixed gas; the combined pipeline is connected to the engine 3 after passing through the flow indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com