Megawatt multi-split wind power speed-increasing gearbox

A megawatt-level, speed-increasing box technology is applied in the field of mega-watt-level multi-split wind power speed-increasing boxes, which can solve the problems of poor mechanical strength, increase processing and installation errors, etc., and achieve the effect of improving service life.

Inactive Publication Date: 2009-09-23

吴小杰

View PDF0 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The biggest disadvantage of the connector is poor mechanical strength, which increases the processing and installation errors. In addition, the temperature difference between the connectors and the deformation caused by different forces are not the same.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

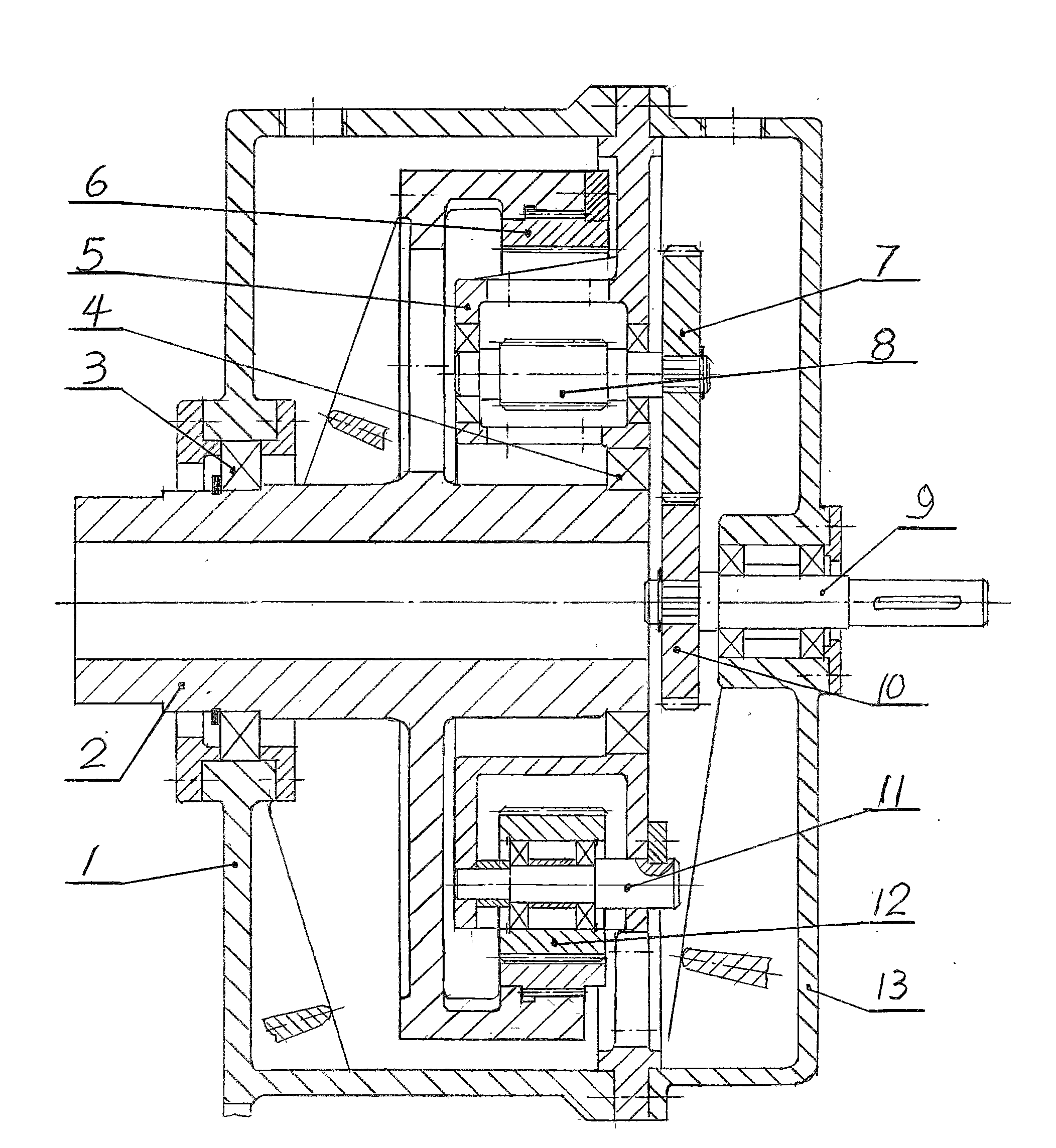

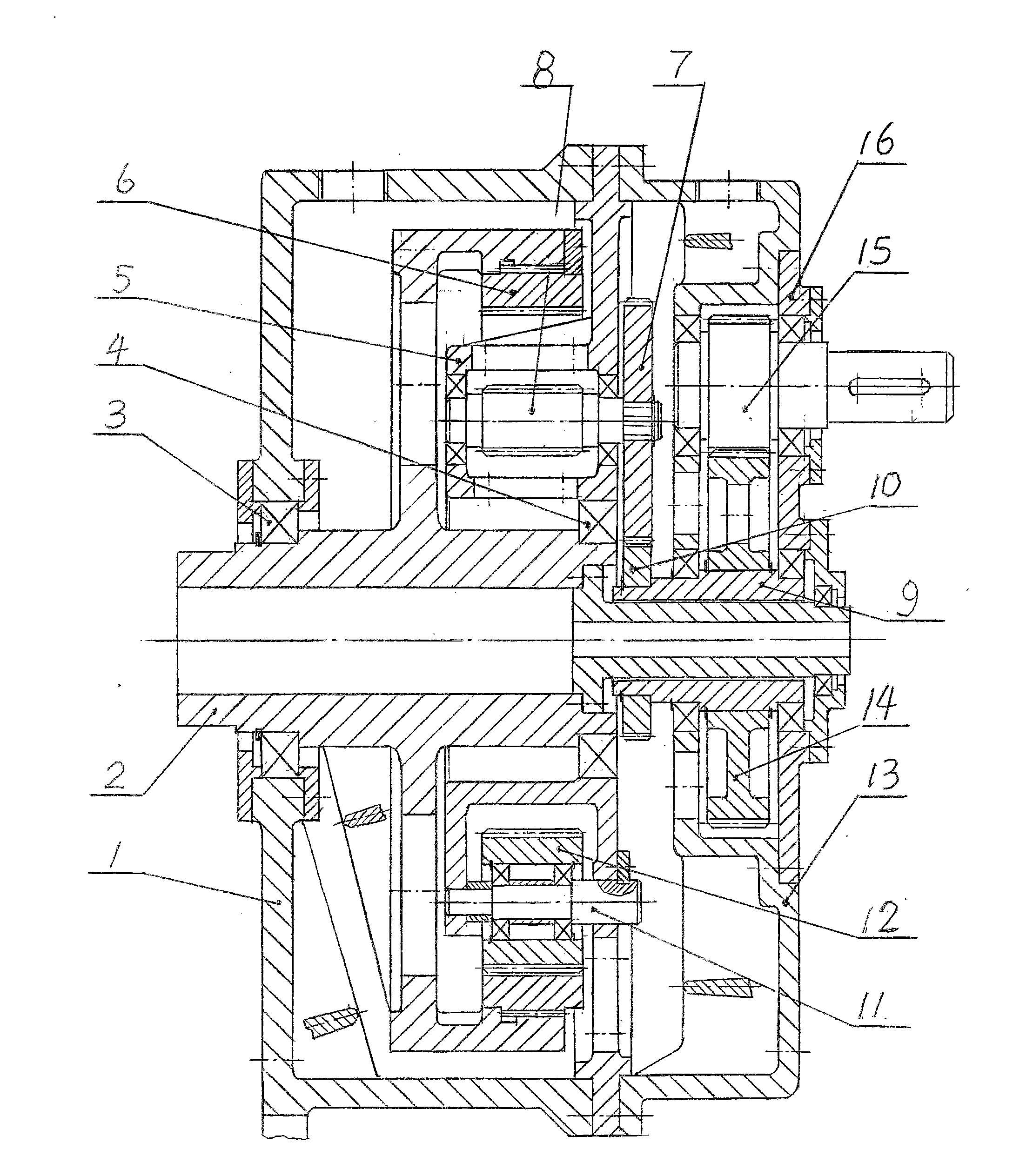

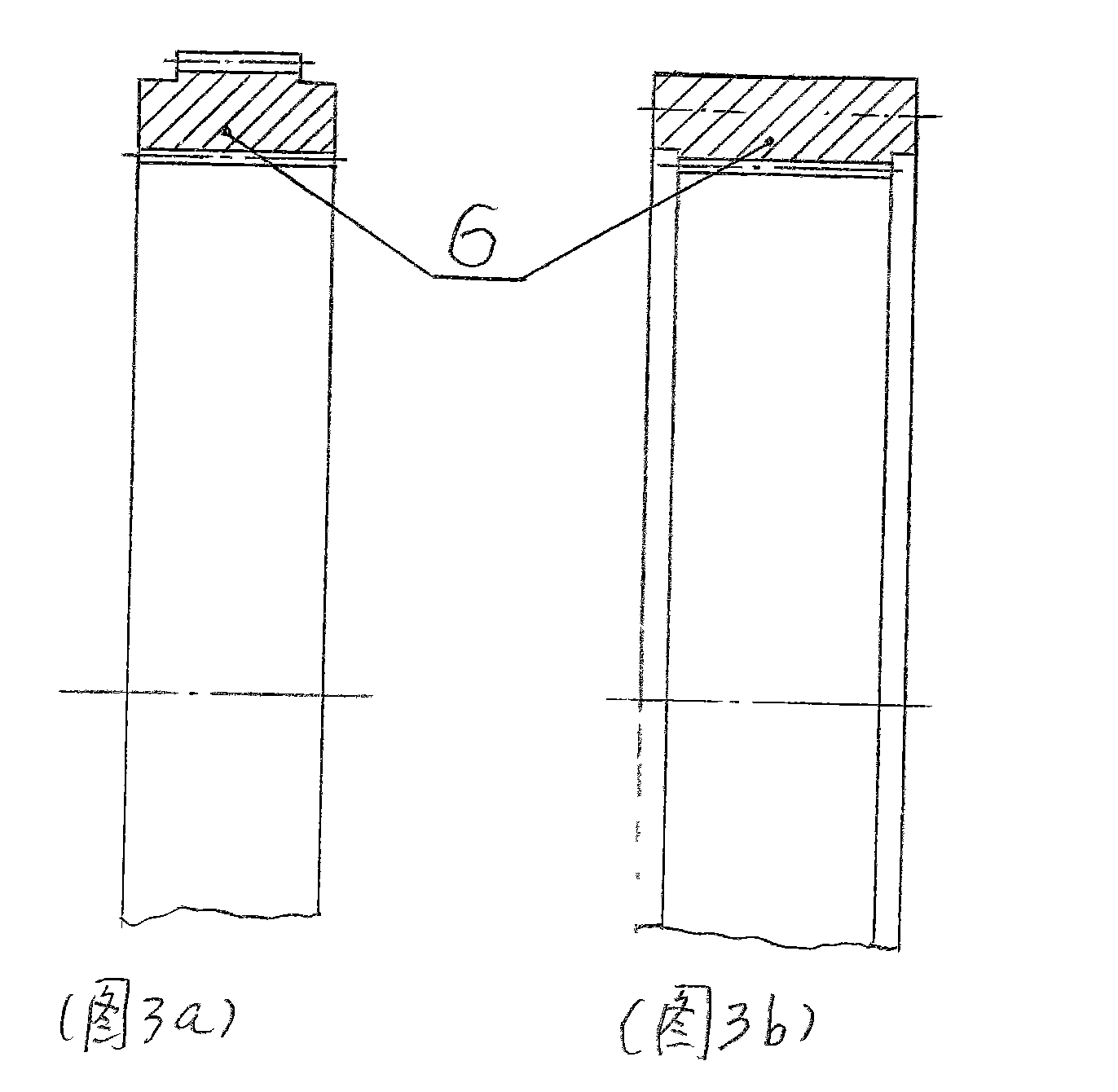

The invention relates to a megawatt multi-split wind power speed-increasing gearbox, in particular to a fixed shaft type multi-split speed-increasing gearbox taking the fixed axle transmission principle as the basis and a movable axle planetary structure as the framework, belonging to the technical field of wind power speed-increasing gearboxes. The speed-increasing gearbox comprises a machine seat, an input shaft, an internal tooth ring, duplicate gears, a central gear or a third-stage speed-increasing gear pair and is characterized in that 3-6 duplicate gears are evenly distributed on the fixed stand, two idle gears are arranged between a shaft gear in each duplicate gear and the internal tooth ring, the transmission gear is meshed with the central gear, and 6-12 split flows or 3-6 split flows are respectively formed. The invention has the advantages that: (1) the weight is lighter by 35 to 45 percent than that of the prior product home and aboard, and the contour is reduced by 40 to 50 percent; (2) the single part is light, and the assembly, the disassembly and the maintenance are convenient; and (3) the domestically produced gear shaper, the gear grinding machine and other devices can be processed into a 3-5MW extra-large machine type, therefore, the manufacturing cost is greatly reduced.

Description

[technical field] The invention relates to the technical field of wind power speed-up, and relates to a megawatt-level multi-shunt wind power speed-up box. [Background technique] Wind energy is an inexhaustible, non-polluting, renewable energy source. It is predicted that by 2020, wind power will become the third largest energy source in my country, so the wind power speed-up box contains a huge market of tens of billions. The gearbox is one of the three core technologies of wind turbines, and the current mainstream models in the world are 1.5-2MW. Since the wind power gearbox is located in a harsh environment and at an altitude of 60 to 70 meters in remote areas, strict requirements are put forward for the gearbox: the service life is 20 years, the bearing life is 130,000 hours, it is as small as possible and light as possible, and it is easy to assemble, disassemble and maintain. Several large enterprises in China have the following patents: (1) NGC's "Wind Power Generat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F03D11/00F16H57/02F16H57/04F16H55/17F03D15/10F16H57/023F16H57/025

CPCF16H1/227F16H37/041Y02B10/30F03D15/00F05B2260/40311

Inventor 吴小杰

Owner 吴小杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com