Water-bath steam heating gasification furnace

A heating type, gasifier technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of gasification temperature deviation from the design value, vibration aggravation, etc., to achieve reliable welding connection, The effect of avoiding water hammer and vibration and reducing the size of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

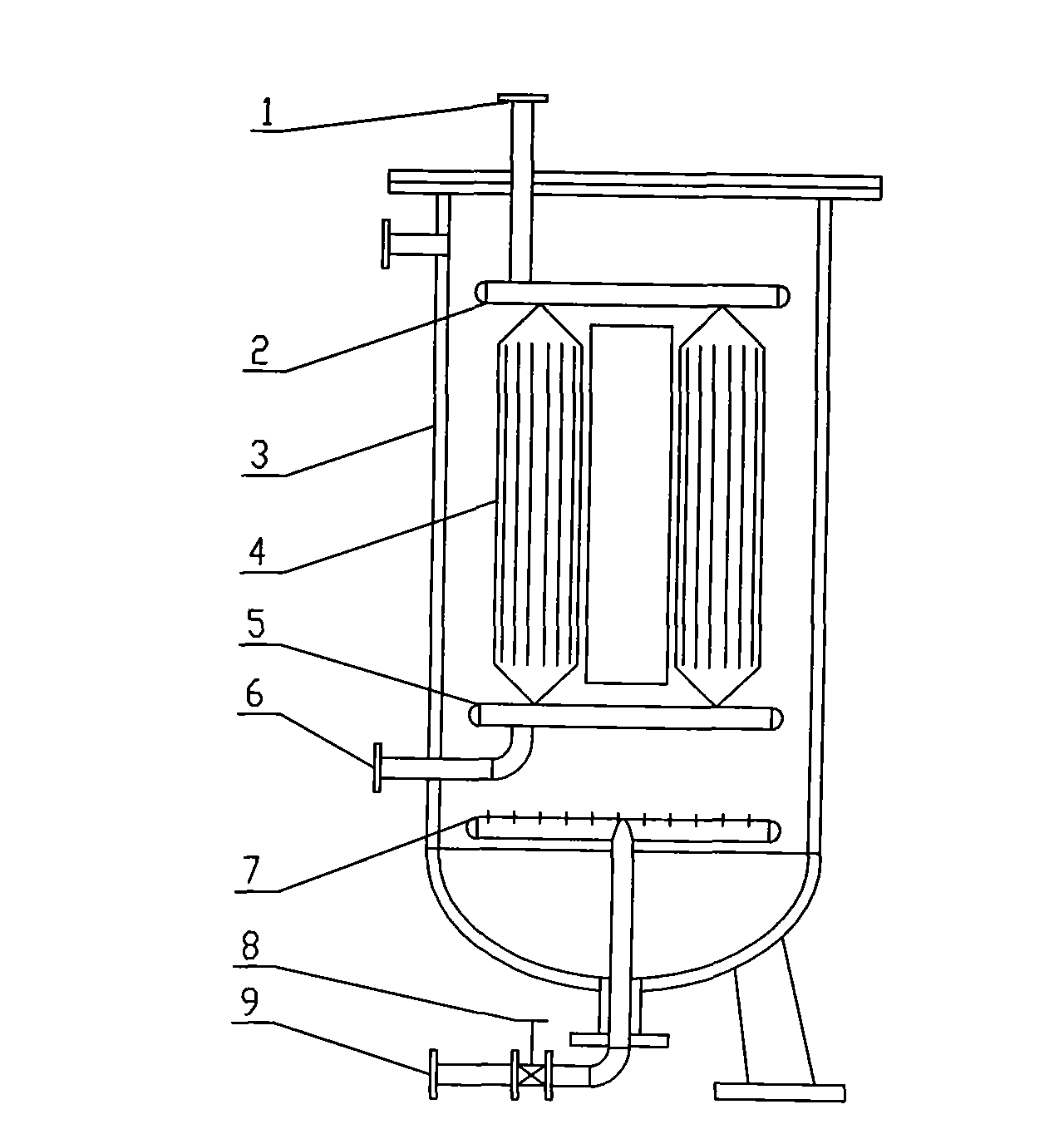

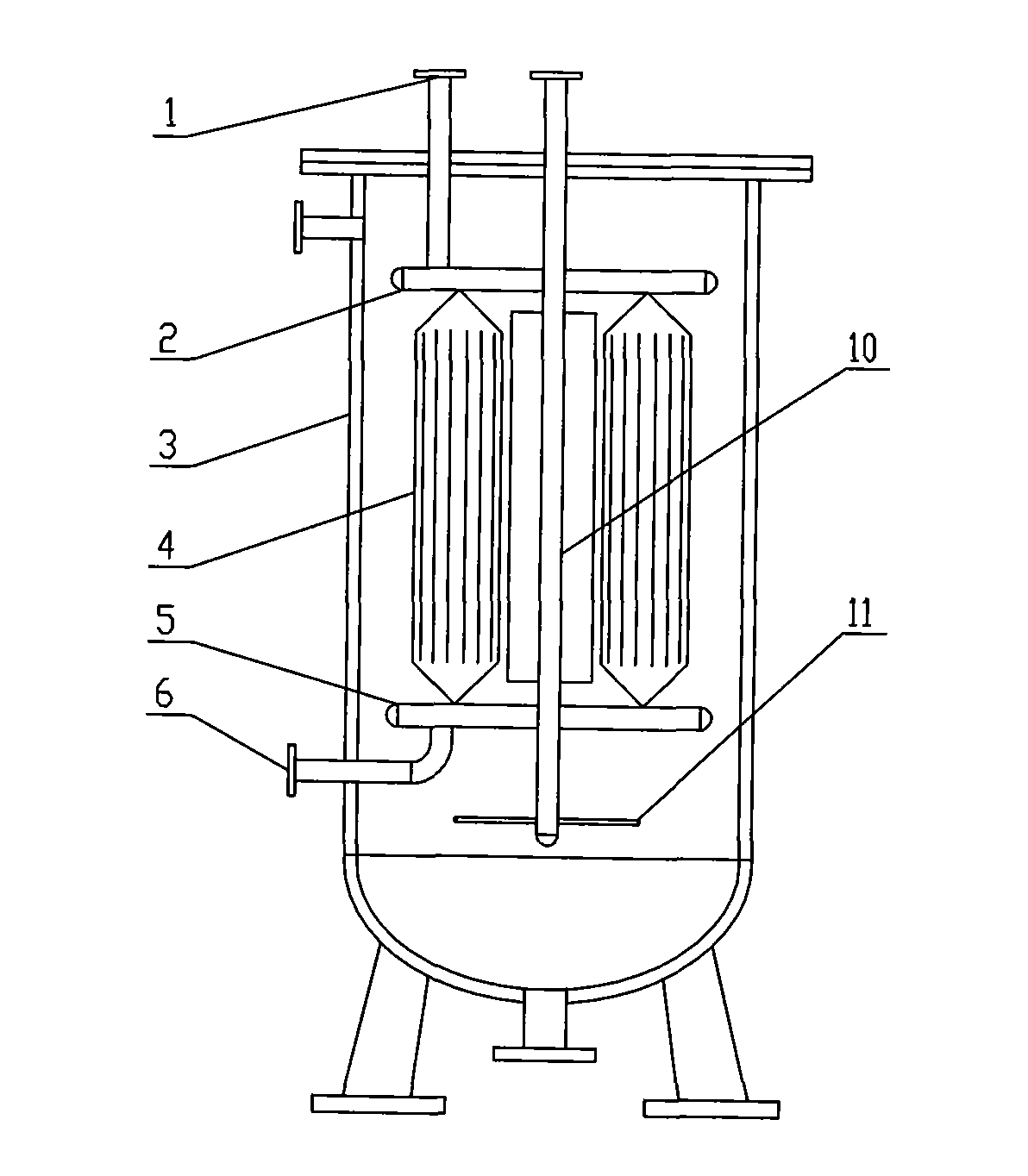

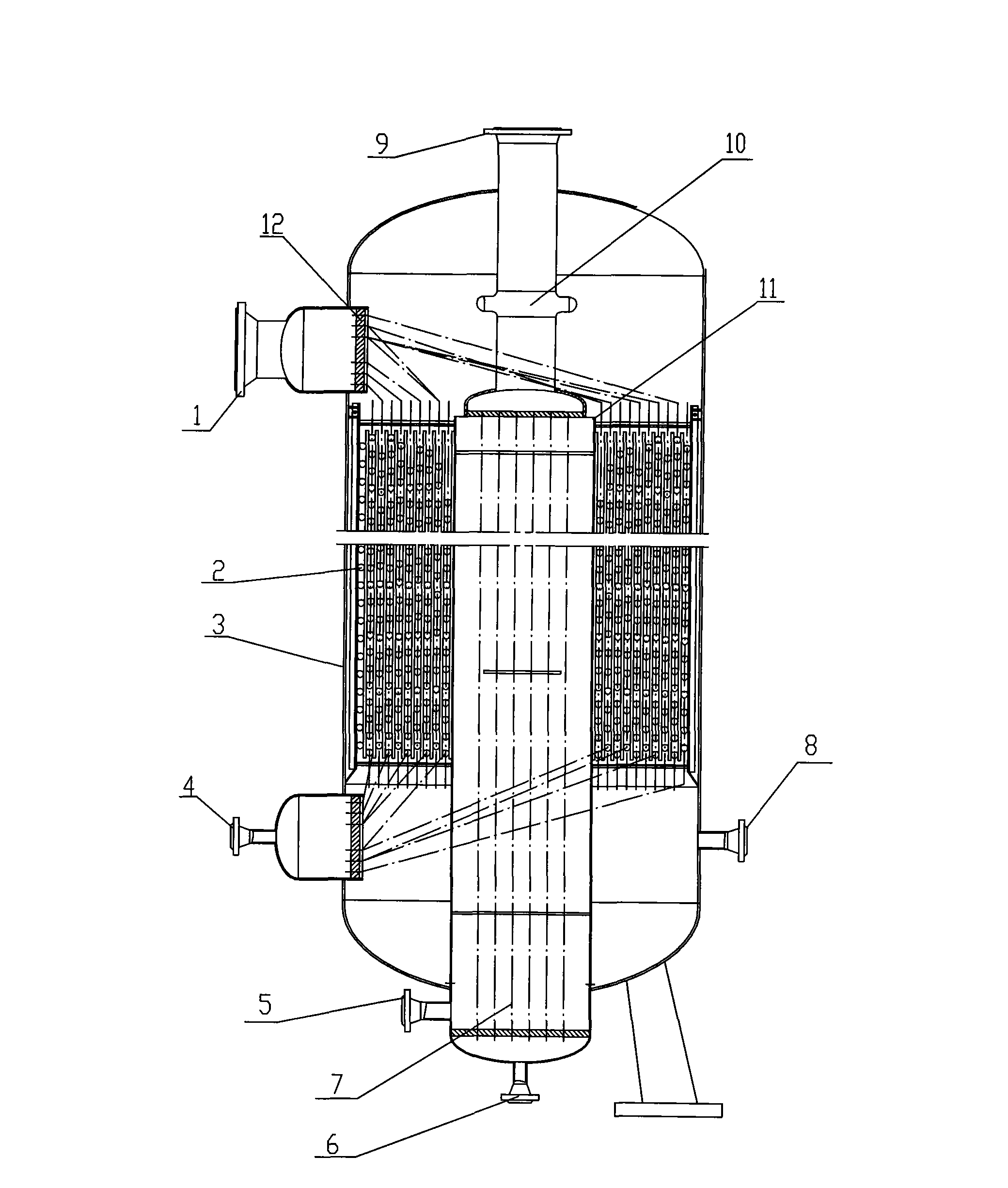

[0021] Referring to Fig. 3, in this embodiment, in the cylinder body 3, a floating tube-sheet heat exchanger 7 is arranged, the water vapor inlet pipe 9 is arranged on the top of the floating tube-sheet heat exchanger 7, and the low-temperature water inlet pipe 5 is arranged on the floating pipe The lower part of the plate heat exchanger 7, the water entering the floating tube sheet heat exchanger 7 from the low temperature water inlet pipe 5 uses the shell 11 of the floating tube sheet heat exchanger 7 as the flow channel, and flows from the floating tube sheet heat exchanger 7 The upper gap is introduced into the cylinder 3;

[0022] A coiled tube heat exchanger 2 is arranged in the cylinder body 3, and a low-temperature liquid inlet tube box 4 and a gas outlet tube box 1 are respectively arranged at the bottom and top of the coiled tube heat exchanger 2 .

[0023] In specific implementation, the corresponding structural settings also include:

[0024] An expansion joint 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com