Heat exchange device

A technology of heat exchange device and heat exchanger, which is applied to thermoelectric device components, thermoelectric devices that only use Peltier or Seebeck effect, etc., and can solve problems such as difficulty in fully releasing thermal stress and reduced reliability of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail by way of example with reference to the accompanying drawings.

[0025] 1. The first embodiment

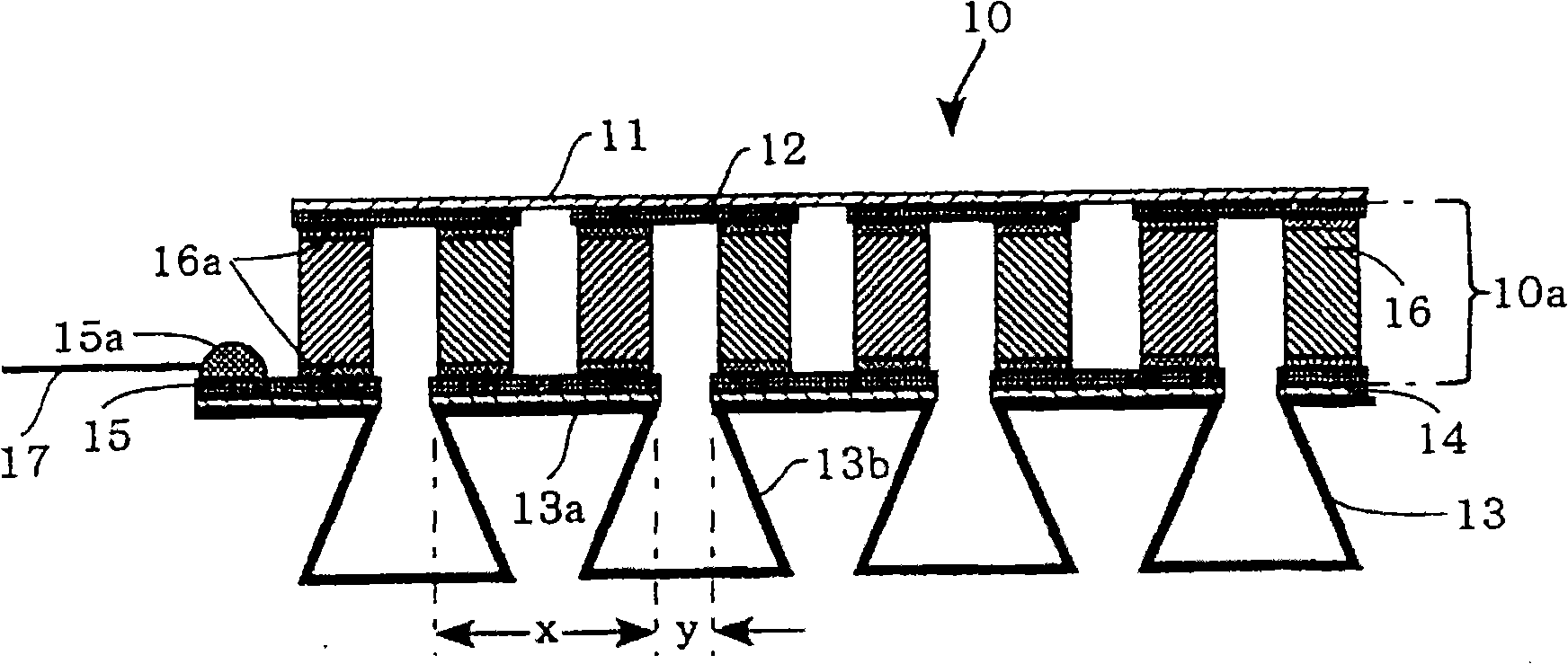

[0026] figure 1 is a cross-sectional view showing the configuration of the heat exchange device 10 according to the first embodiment of the present invention. The heat exchanging device 10 includes a substrate 11, a heat dissipating electrode 12 formed under the substrate 11, a plurality of corrugated fins 13 (commonly serving as a heat exchanger on the heat absorbing side), via a A permanent insulating resin layer 14 is connected to a heat absorbing electrode 15 on the upper surface of the corrugated fin 13, and a plurality of thermoelectric elements 16 electrically connected in series between the electrodes 12 and 15 via a solder layer (or metal) 16a.

[0027] A pair of terminals 15 a is formed on one end of the heat absorbing electrode 15 to establish electrical connection with the lead wire 17 . The thermoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com