Neon-light electronic transformer

A technology for electronic transformers and neon lights, applied in transformers, inductors, circuits, etc., can solve the problems of protection failure, troubled neon lights, and easy protection by mistake, and achieve the effect of improving operation stability, simplifying circuit structure, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

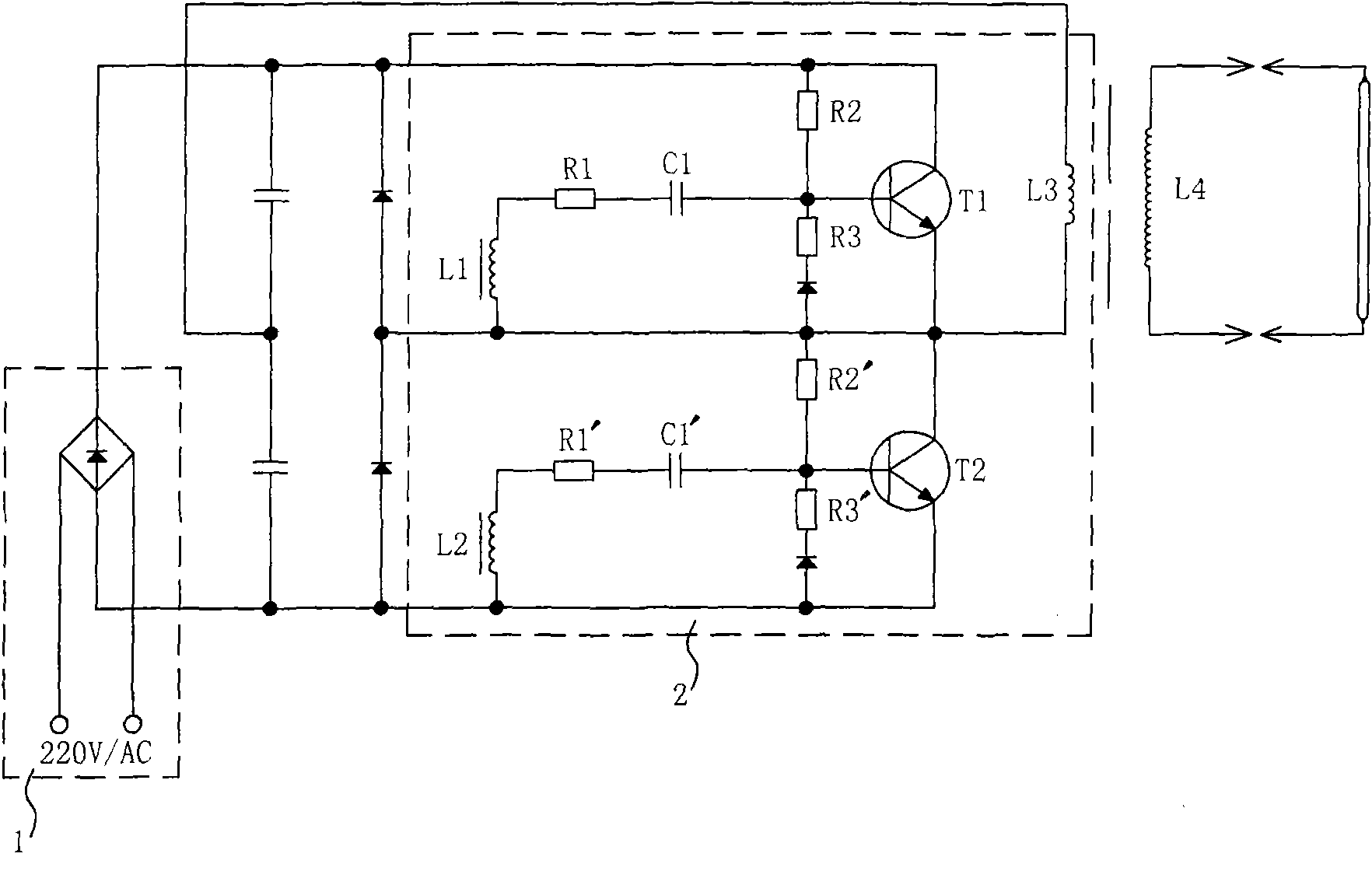

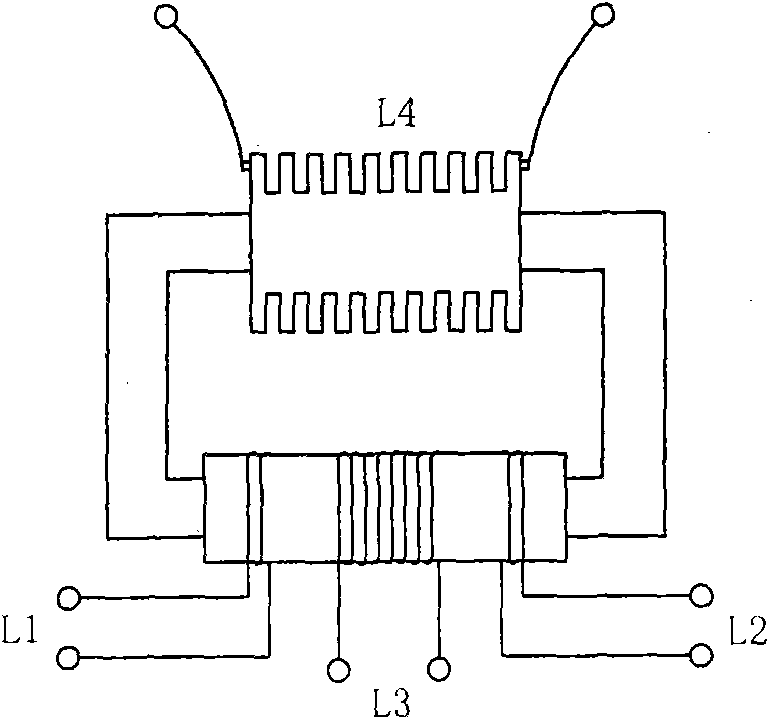

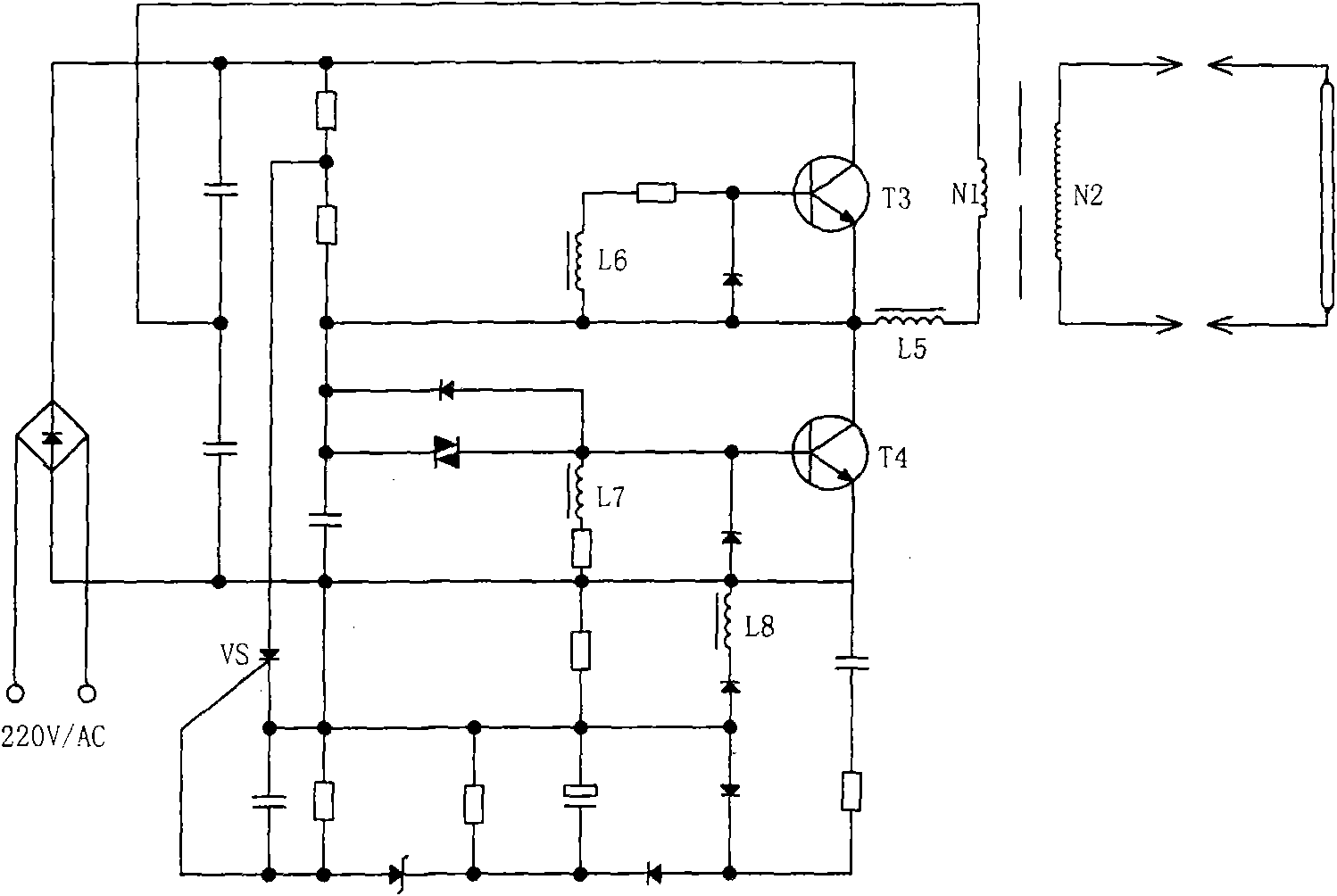

[0012] refer to figure 1 , figure 2 As shown, the neon electronic transformer of the present invention includes a power input circuit 1, a self-excited oscillation circuit 2 and an output coil L4, and the self-excited oscillation circuit 2 includes bias current resistors R2, R2', feedback coils L1, L2, secondary coils L3, Capacitors C1, C1', current-limiting resistors R1, R1', feedback coils L1, L2, secondary coil L3, output coil L4 are wound on the same magnetic core, feedback coils L1, L2 have 2 to 4 turns optional, secondary The primary coil L3 is selected between 90 and 100 turns; one end of the bias current resistor R2, R2' is respectively connected to the collectors of the two triodes T1, T2, and the other end is respectively connected to the feedback capacitor C1 and the coil L1, the capacitor C1' and the feedback coil L2 The formed series circuit is connected in parallel to the bases of transistors T1 and T2, and the current-limiting resistors R1 and R1' are respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number of turns | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com