Composite sheet and absorbent article comprising composite sheet

A composite sheet, stretchable technology, applied in the direction of absorbent pads, fabrics, layered products, etc., can solve the problems of increased production costs, larger gaps between fibers, and exudation of adhesives, and achieves the effect of good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, examples of the present invention will be described, but these examples are merely illustrations suitable for describing the present invention, and do not limit the present invention in any way.

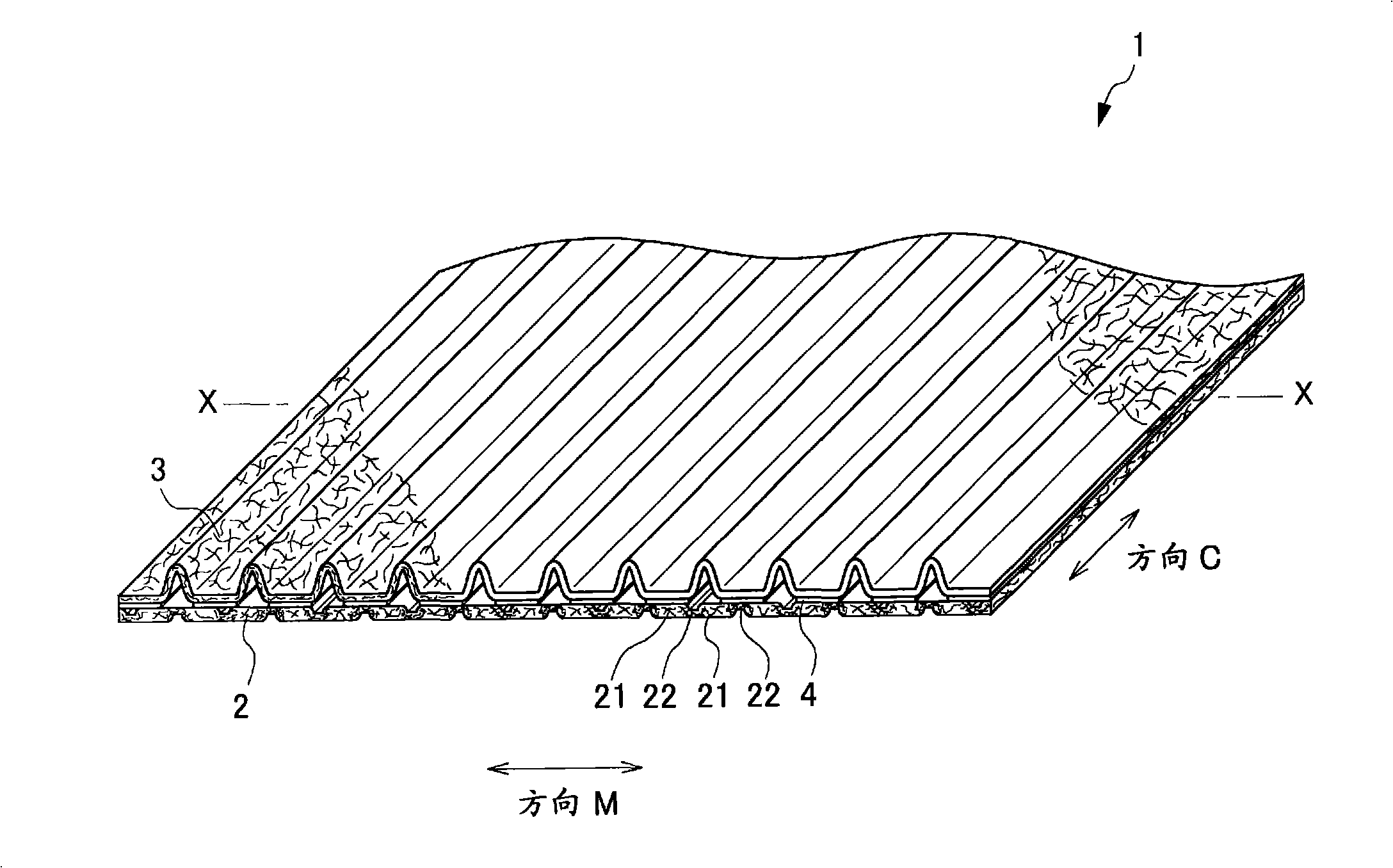

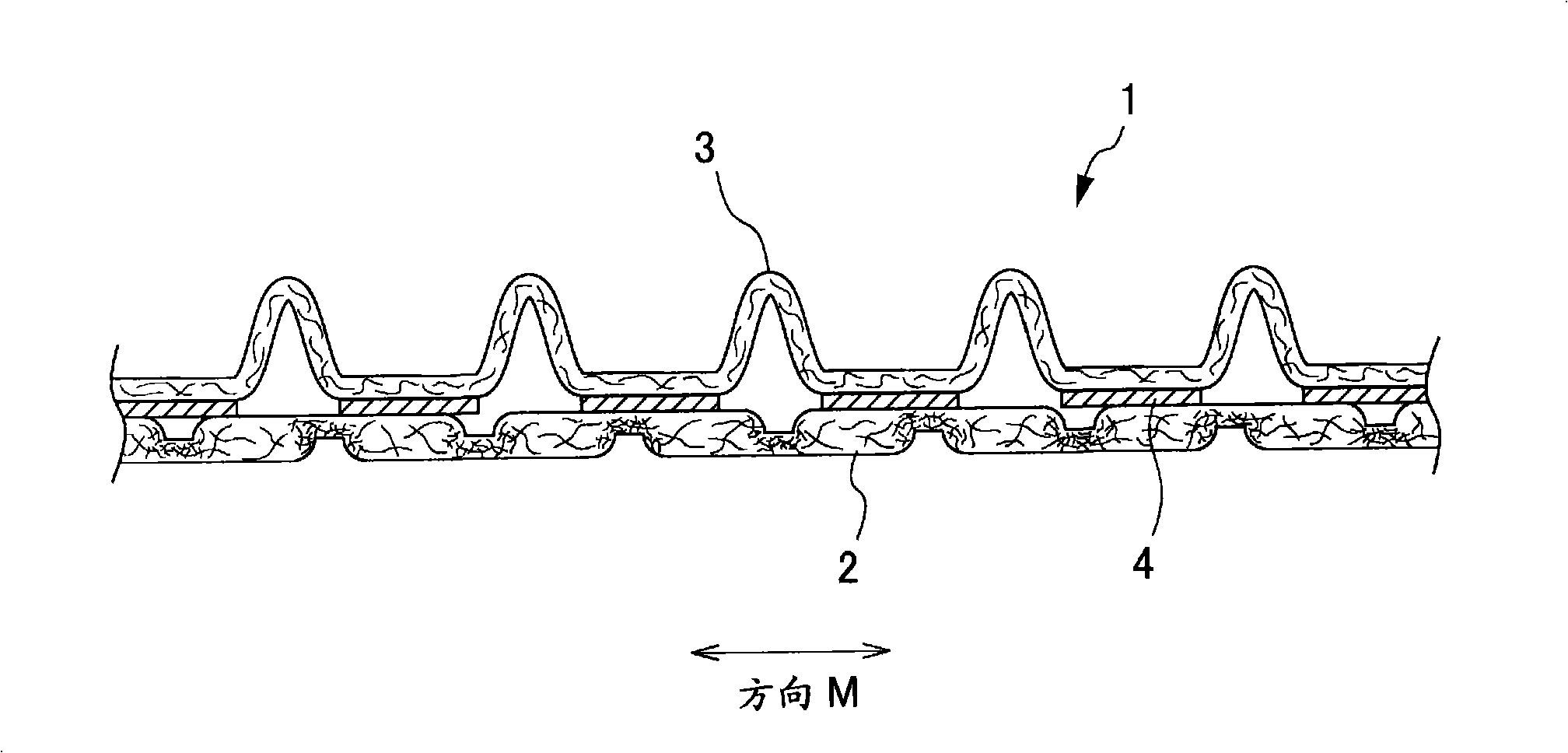

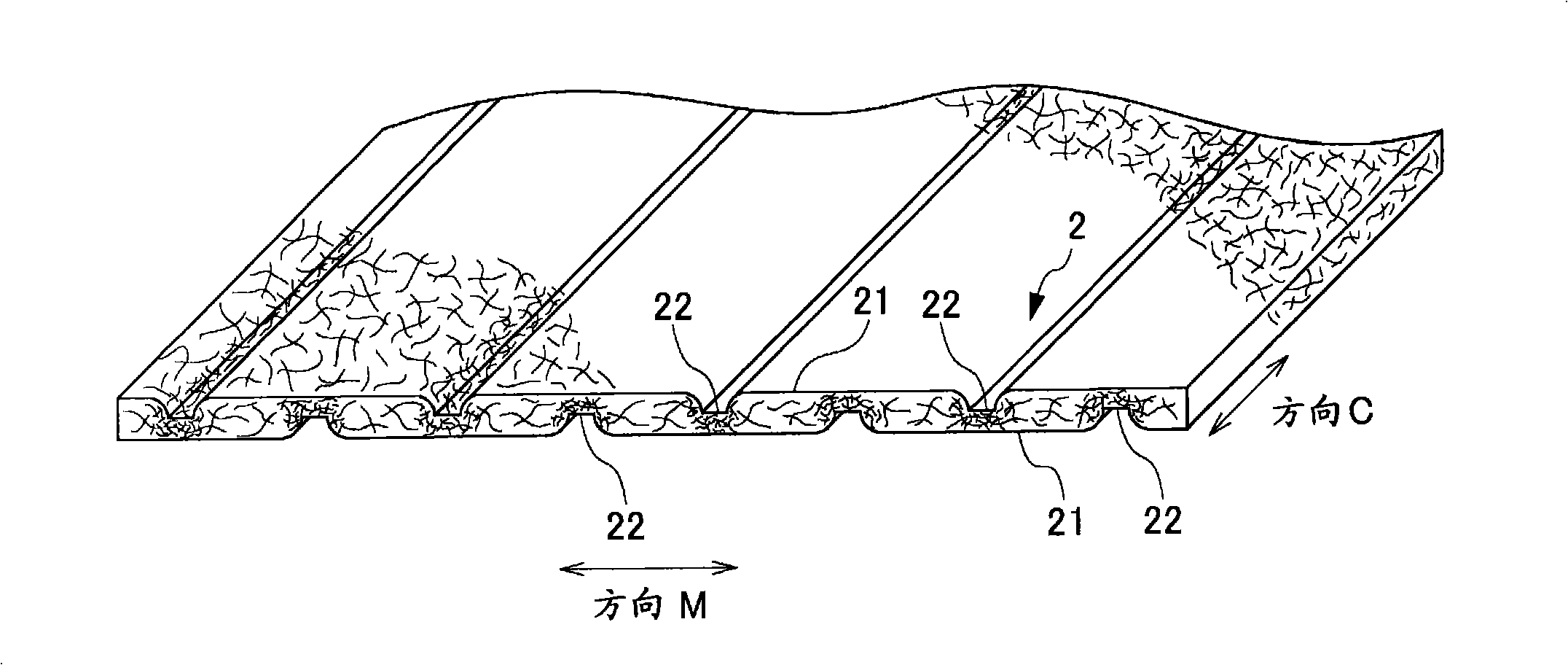

[0098] The stretchable nonwoven raw fabric 5 was prepared by setting the mixing ratio (weight ratio) of polypropylene fibers (PP) and polyurethane fibers (TPU) to 55:45. Next, the stretchable nonwoven raw fabric 5 is gear-drawn by shaping rollers 10, 10' to obtain a stretchable nonwoven fabric 2. The basis weight of stretchable non-woven fabric 5 is 35g / m 2 , the basis weight of the stretchable nonwoven fabric 2 in a relaxed state is 38g / m 2 .

[0099] Then, the stretchable nonwoven fabric 2 was thermally welded to the nonstretchable nonwoven fabric 3 in a state stretched by 1.88 times. In addition, the coating pattern of the adhesive is spiral coating, and the basis weight of the hot melt adhesive is 5g / m 2 (as Example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| base weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com