Method for operating a reagent metering valve and apparatus for carrying out the method

A technology of metering valves and reagents, which is applied in the direction of noise reduction devices, exhaust devices, separation methods, etc., can solve the problems of incomplete reduction of nitrogen oxides, odor interference, high reagent consumption, etc., to avoid high temperature, low cost, and realize The effect of component protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

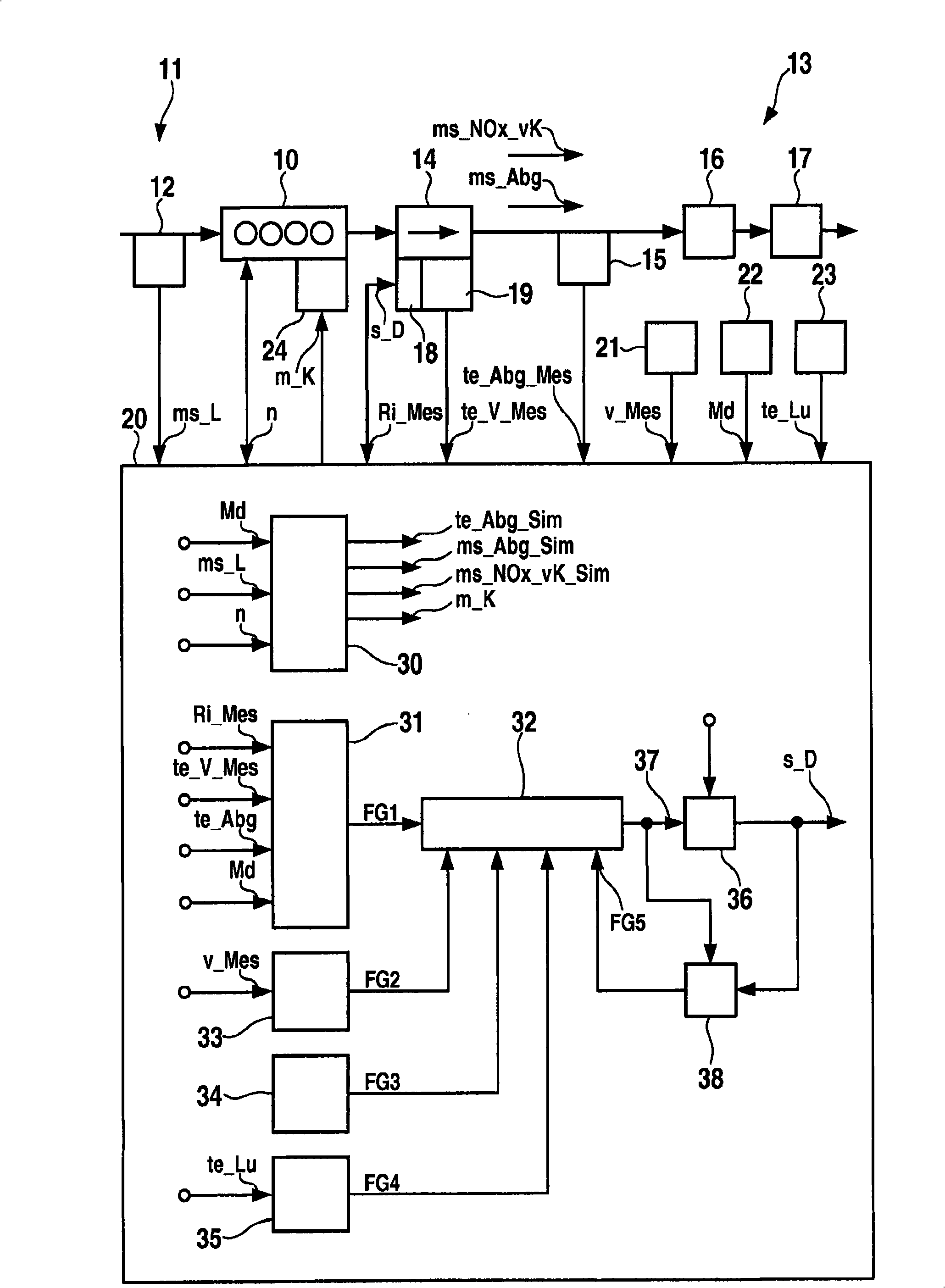

[0024] figure 1 An internal combustion engine 10 is shown, an air detector 12 is arranged in its intake region 11 and a metering device 14 , an exhaust gas temperature sensor 15 , a catalytic converter 16 and a particle filter 17 are arranged in its exhaust region 13 .

[0025] The exhaust gas mass flow ms_abg occurs in the exhaust region and the NOx mass flow ms_NOx_vK occurs upstream of the catalytic converter 16 .

[0026] The metering device 14 includes a solenoid valve 18 and a metering valve temperature sensor 19 .

[0027] Air detector 12 supplies air signal ms_L to control device 20 , internal combustion engine 10 supplies rotation signal n and exhaust gas temperature sensor 15 supplies measured exhaust gas temperature te_abg_Mes.

[0028] The solenoid valve 18 supplies the control unit 20 with a coil internal resistance Ri_Mes, and the metering valve temperature sensor 19 supplies the measured metering valve temperature te_V_Mes.

[0029] In addition, a speed sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com