Device and method for removing liquid from a surface of a disc-like article

一种物品、液体的技术,应用在半导体/固态器件制造、电气元件、电路等方向,能够解决无法清除液体等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

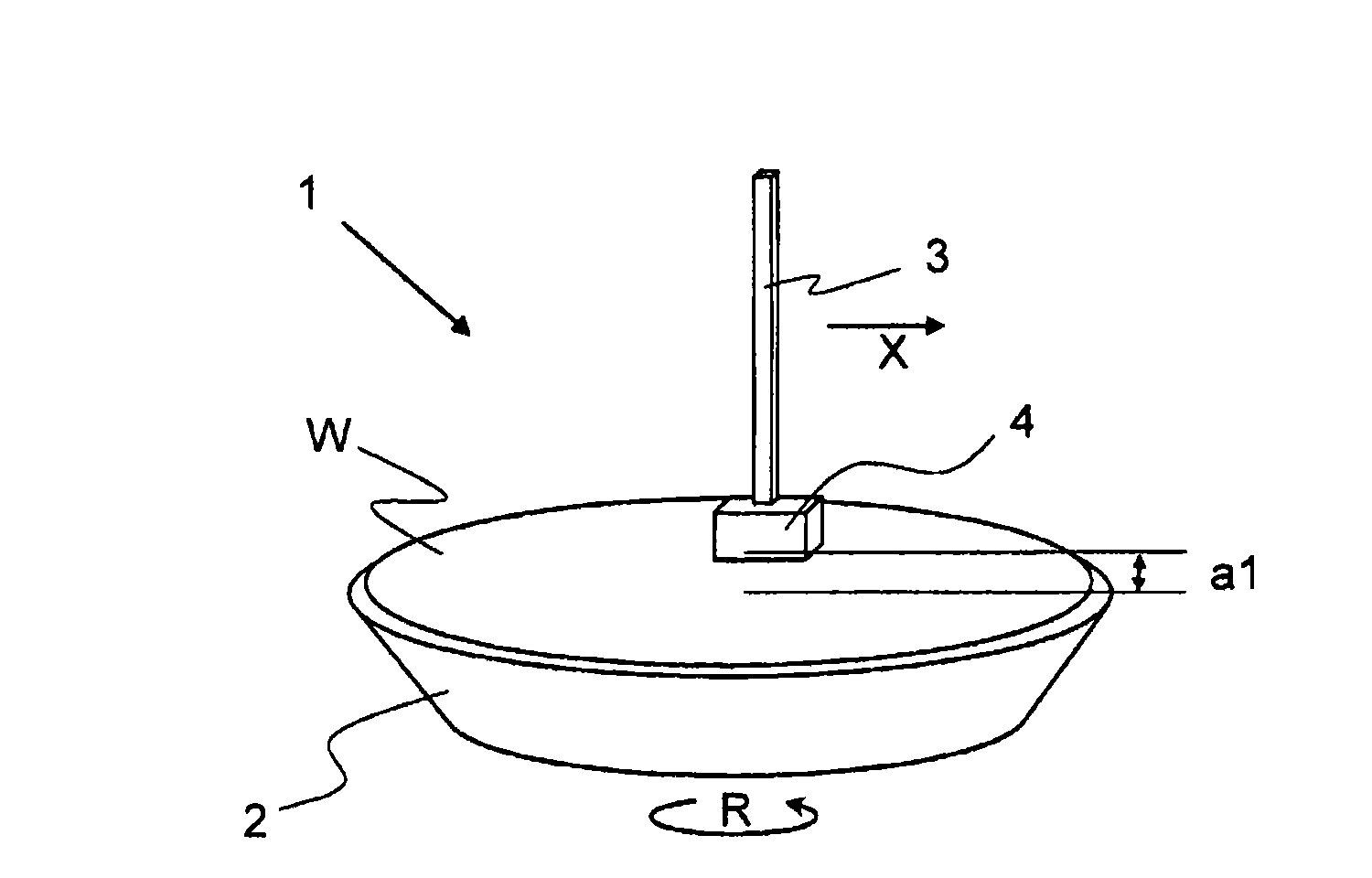

[0054] figure 1 A device 1 for removing liquid from the surface of a pan-shaped article W is shown according to a preferred embodiment of the invention. The device comprises a rotating chuck 2 for holding a disc-shaped article W and an arm 3 on which a nozzle assembly 4 is mounted. In this case, the disc-shaped article is a semiconductor wafer (wafer). The rotary chuck 2 can rotate (as shown by arrow R). Nozzle assembly 4 includes a plurality of nozzles with downward facing holes. Through these nozzles, different fluids are discharged towards the upward facing surface of the wafer. The arm 3 and nozzle assembly are connected to a motion mechanism (not shown) to move the nozzle assembly 4 across the surface of the wafer. The arm 3 can also move in a straight line (eg across a radius as indicated by arrow X), or can perform a rotational movement. As the nozzle assembly moves across the wafer, only a fixed distance a1 is maintained between the nozzle assembly and the wafer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com