Batch dishwasher with waste water heat recovery

A dishwasher, batch technology, applied in the direction of tableware washing machine/rinsing machine, dishwasher application, water heater, etc., can solve the problems of easy staining, lack of controllability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

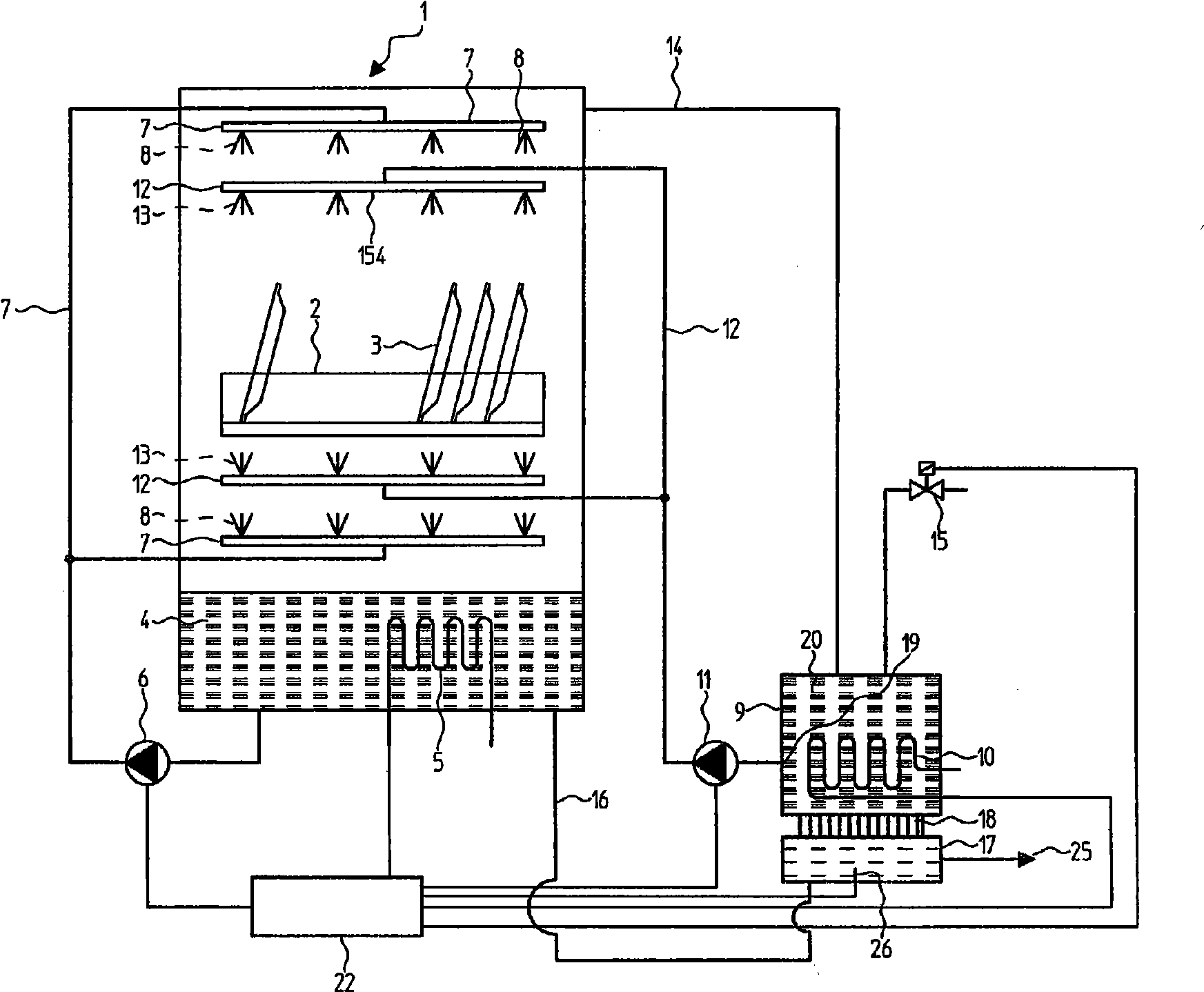

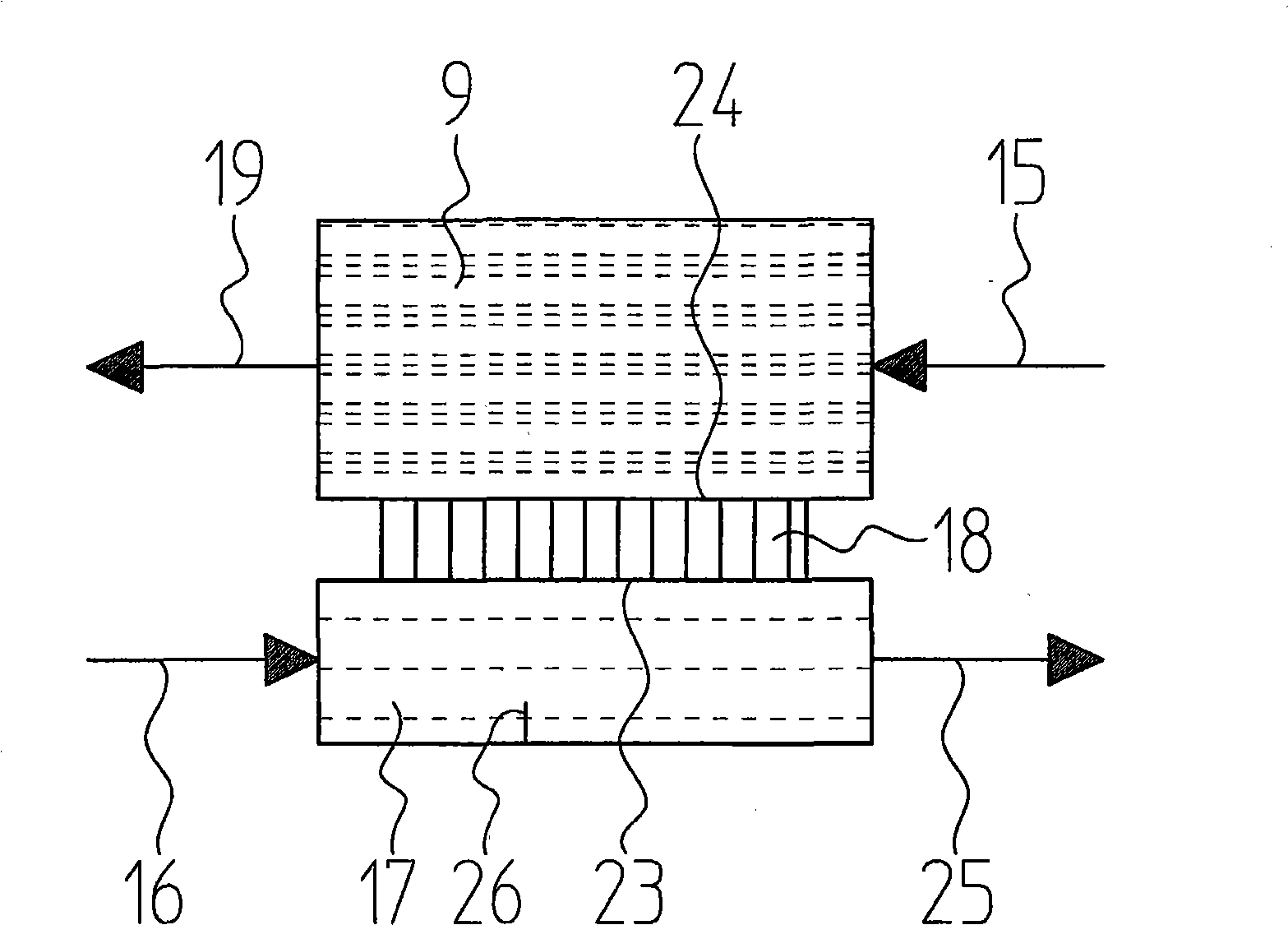

[0024] According to attached figure 1 , which shows a washing machine, in particular a batch dishwasher with a single chamber. A bracket 2 for accommodating the washing utensils 3 to be cleaned is arranged in the single chamber of the washing machine, and the bracket is fixed in the washing chamber by suitable assembly. The schematically shown dishwasher 1 can be in the form of a front loading unit, a top loading unit or various other through-units. The batch dishwasher 1 comprises a tank 4 for holding a cleaning solution. A heater 5 is provided in the tank 4 to heat the cleaning solution. The cleaning solution contained in the tank 4 is mixed with the detergent and heated to the corresponding required temperature by means of the heater 5 .

[0025] The batch dishwasher 1 also includes a controller 22 for controlling the washing programs to be executed accordingly. The controller drives, for example, a pump 6 to circulate the cleaning fluid, which pump delivers the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com