Corner post-free carriage for a railway vehicle

A railway freight car and corner post technology is applied in the field of the carriage structure of the railway freight car, which can solve the problems of increasing the manufacturing complexity and product cost, increasing the manufacturing cost of the carriage, and increasing the processing cost of the carriage, so as to reduce the total weight of the carriage and reduce the energy consumption of the locomotive. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

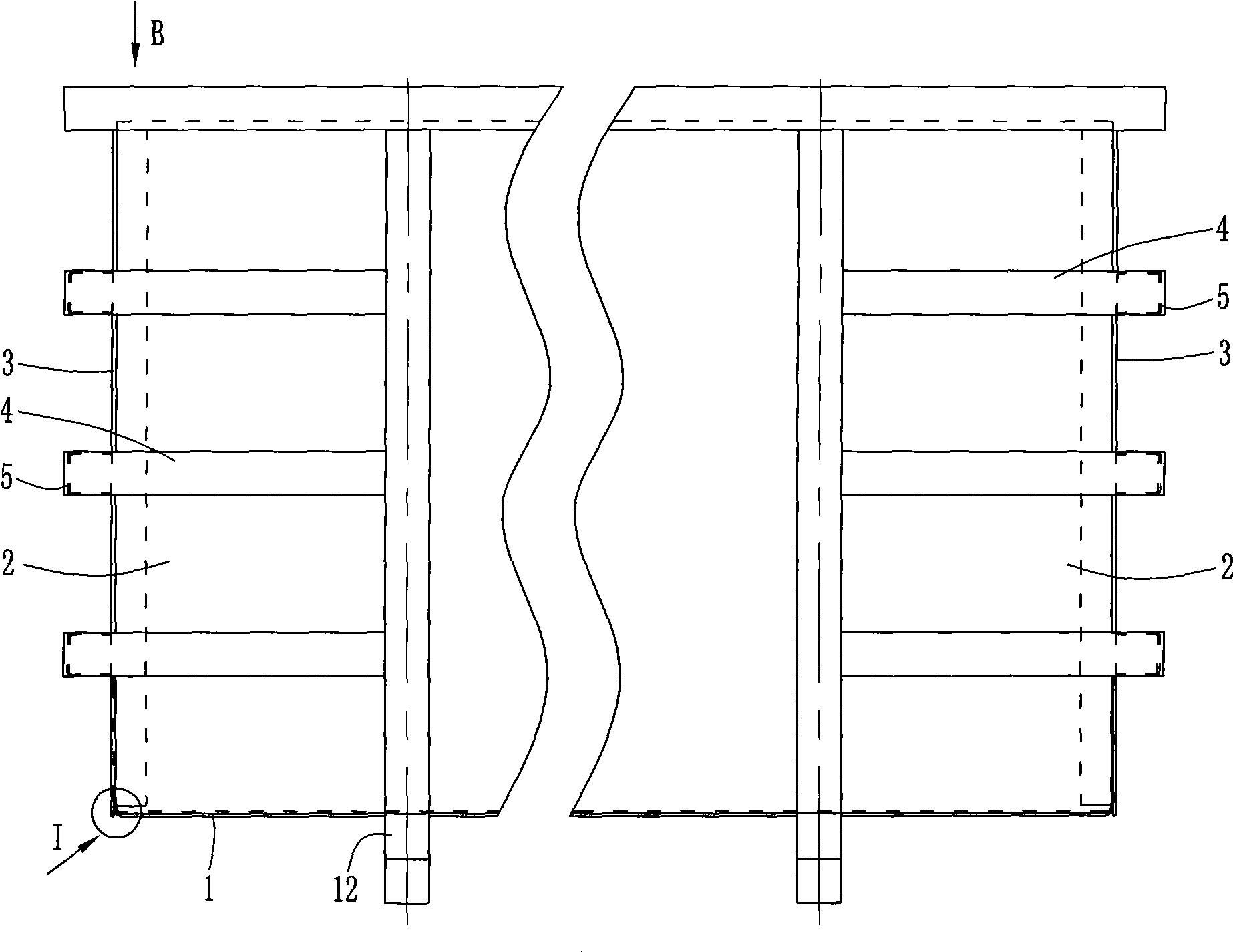

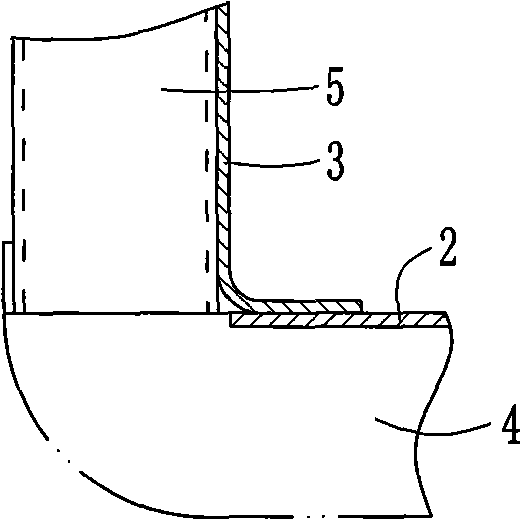

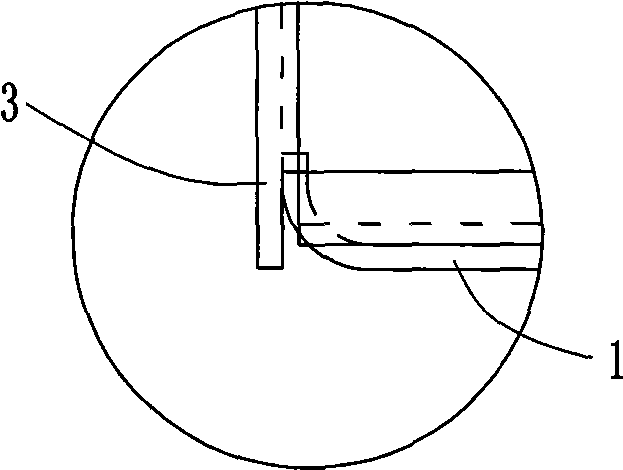

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is composed of floor 1, side wall panels 2, end wall panels 3, side transverse strips 4, end transverse strips 5, beams 10, center beams 11, side columns 12 and longitudinal beams 13, among which the side walls The board 2 is located on both sides of the floor 1, and the bottom edge of the side wall board 2 is bent inward, and the bent part overlaps with the corresponding side of the floor 1, and is fixed by welding (see Figure 4 ). The end wall panels 3 are located at both ends of the floor 1. The end wall panels 3 present a trapezoidal cross-sectional shape with a large top and a small bottom. side, the flange is lapped and welded with the corresponding end of the side wall panel 2 (see figure 2 ). The two ends of the floor 1 are bent upwards to form an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com