Pressure control valve

A pressure control and valve core technology, applied in the field of pressure control valves, can solve the problems of reduced cooling capacity, compressor shutdown, compressor capacity reduction, etc., and achieves the effect of reducing the passage area and achieving good control reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

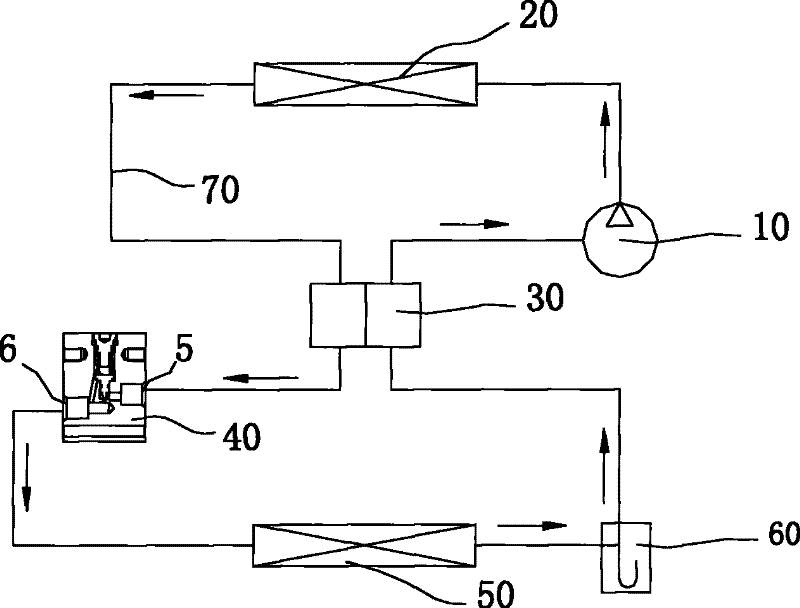

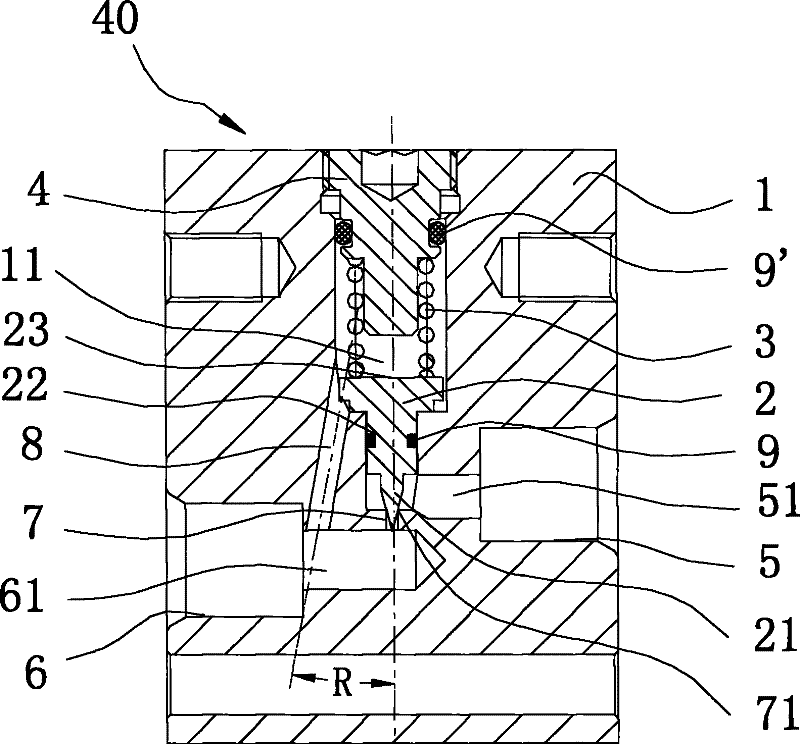

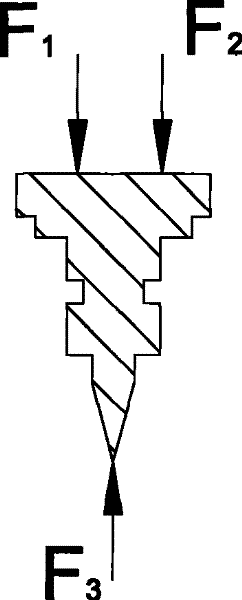

[0051] figure 2 It is a structural schematic diagram of the pressure control valve of the preferred solution of the present invention. Such as figure 2 As shown, the pressure control valve 40 includes: a valve body 1; a high-pressure chamber 51 and a low-pressure chamber 61 arranged in the valve body 1, the high-pressure chamber 51 and the low-pressure chamber 61 are connected by a throttling passage 7, and the high-pressure chamber The high-pressure port 5 of the chamber 51 is connected to the outlet side of the cooler 20 through the heat exchanger 30, the low-pressure port 6 of the low-pressure chamber 61 is connected to the inlet side of the evaporator 50, and a sealing member is provided between the high-pressure chamber 51 and the inner chamber 11; The inner chamber 11 of the valve body 1 is provided with a valve core 2; the valve port 71 is located on the throttling passage 7 and opens to the high-pressure chamber 51; when the valve core 2 moves back and forth relativ...

Embodiment 2

[0064] This embodiment combines the attached Figure 5 Preferred embodiments of the pressure control valve are disclosed. Such as Figure 5 Schematic diagram of the structure of the pressure control valve shown.

[0065] A bypass through hole 8' is provided between the low-pressure chamber 61 and the inner cavity 11, and the pressure in the low-pressure chamber 61 is introduced into the inner cavity 11 to act on the valve core 2. The axis of the bypass through hole 8' is in line with the valve core. The axes of the cores 2 intersect with an angle R between them. The difference from the pressure control valve shown in Embodiment 1 is that in Embodiment 1, one end of the bypass through hole 8 opens to the inner cavity 11, and its opening faces the valve core 2 no matter where the valve core 2 moves, while In this embodiment, when the valve port 71 is fully opened, the opening of the bypass hole 8 to the inner cavity 11 is higher than the end surface 23 of the valve core 2, no...

Embodiment 3

[0069] This embodiment combines the attached Figure 7 Preferred embodiments of the pressure control valve are disclosed. Such as Figure 7 Schematic diagram of the structure of the pressure control valve shown.

[0070] A bypass through hole 8" is provided between the low-pressure chamber 61 and the inner cavity 11, so that the pressure in the low-pressure chamber 61 is the same as that of the inner cavity 11. The structure of the pressure control valve described in this embodiment is the same as that described above. The main difference of the embodiment is that the axis of the bypass hole 8" is parallel to the axis of the spool, and the distance between the axis of the bypass hole 8" and the axis of the spool 2 is greater than the maximum radius of the spool 2 , Correspondingly, the cross-sectional size of the inner chamber 11 is also increased compared with the above two embodiments. Other structures of the pressure control valve are basically similar to the previous emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com