Turbine disc and gas turbine

A turbine disk and cooling hole technology, which is applied to the cooling of turbine/propulsion devices, mechanical equipment, engine functions, etc., can solve the problems of thicker thickness, high cost, and insufficient durability of turbine disks, etc., to alleviate stress concentration , realize the effect of reducing weight and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

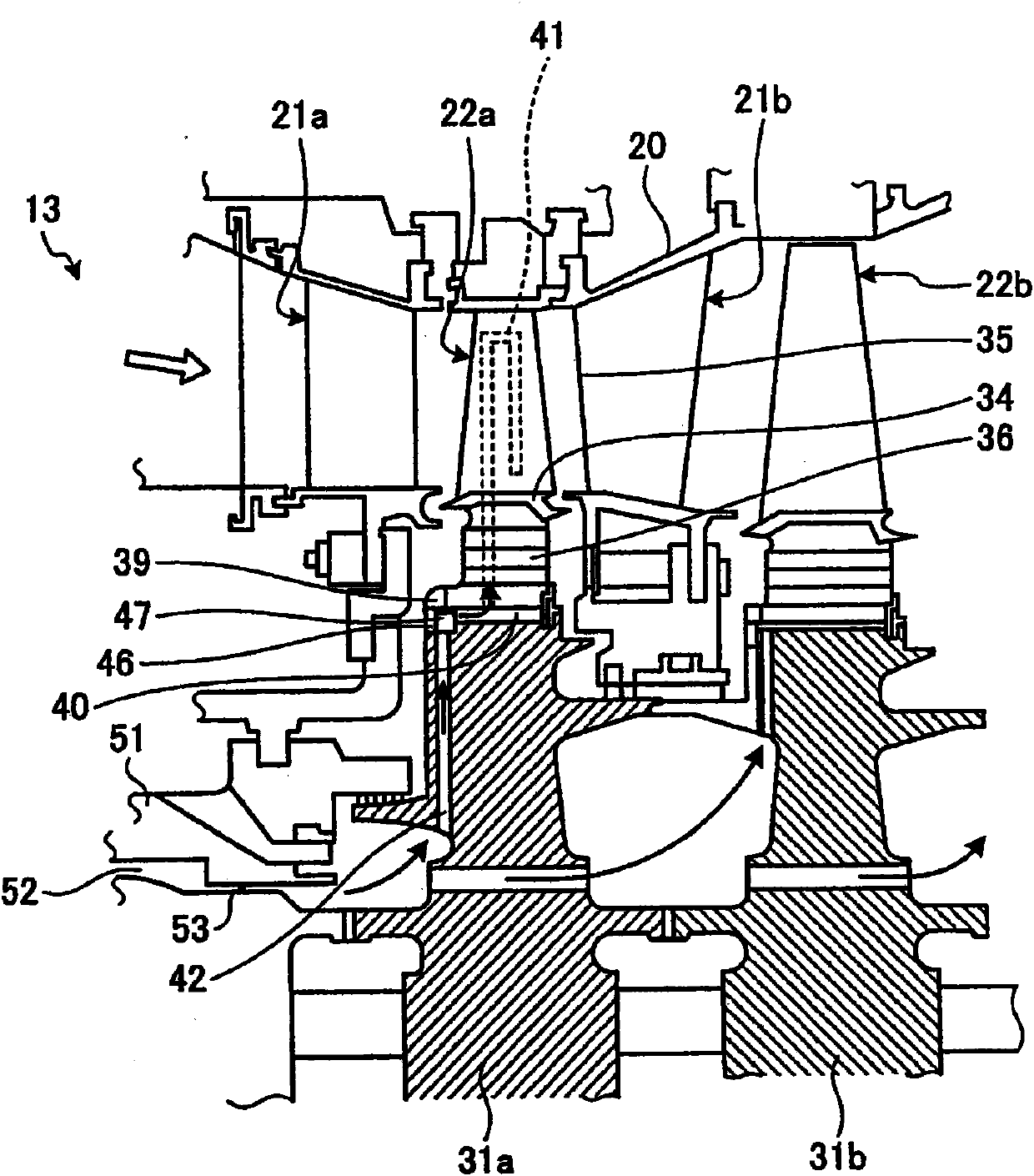

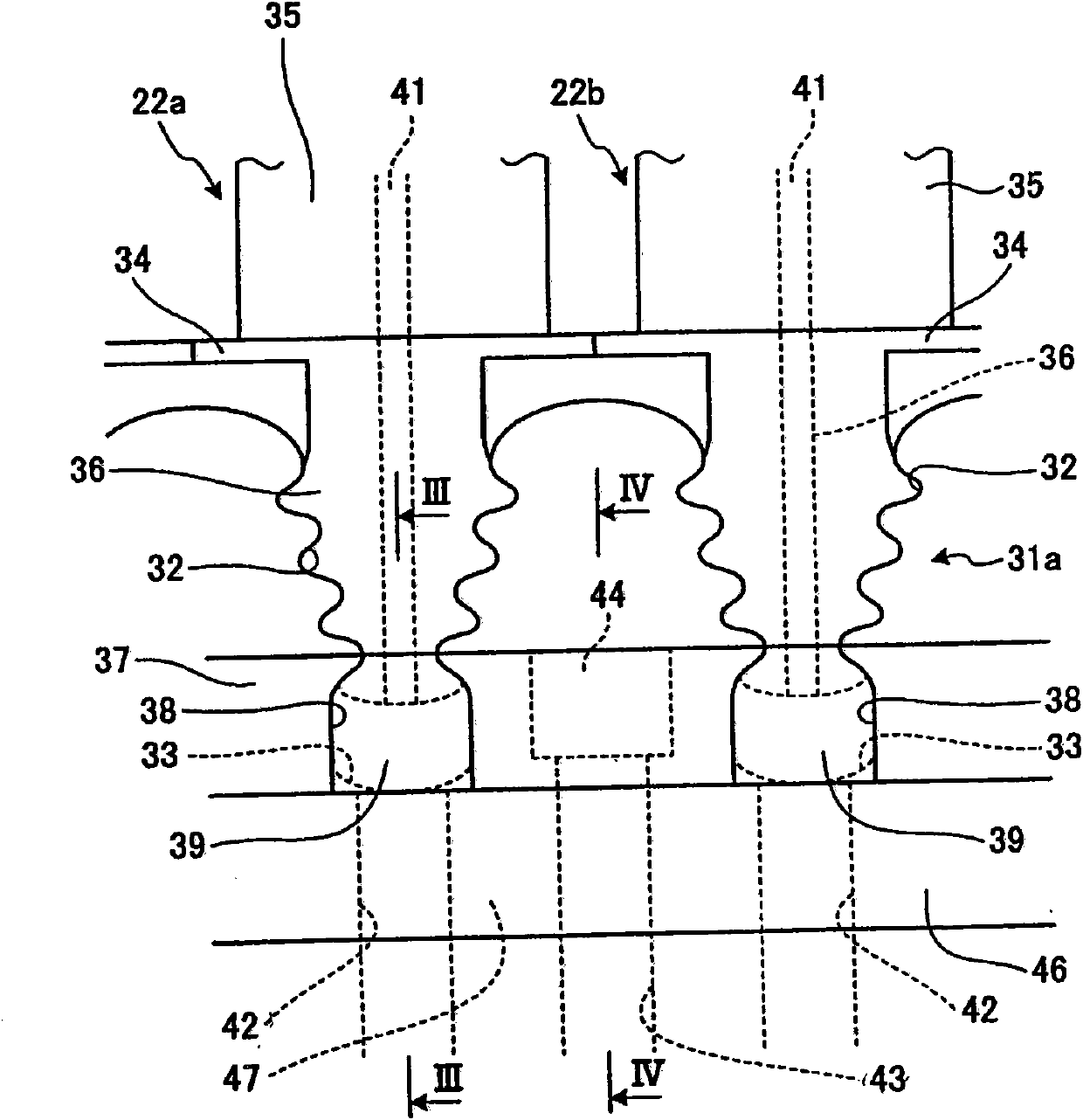

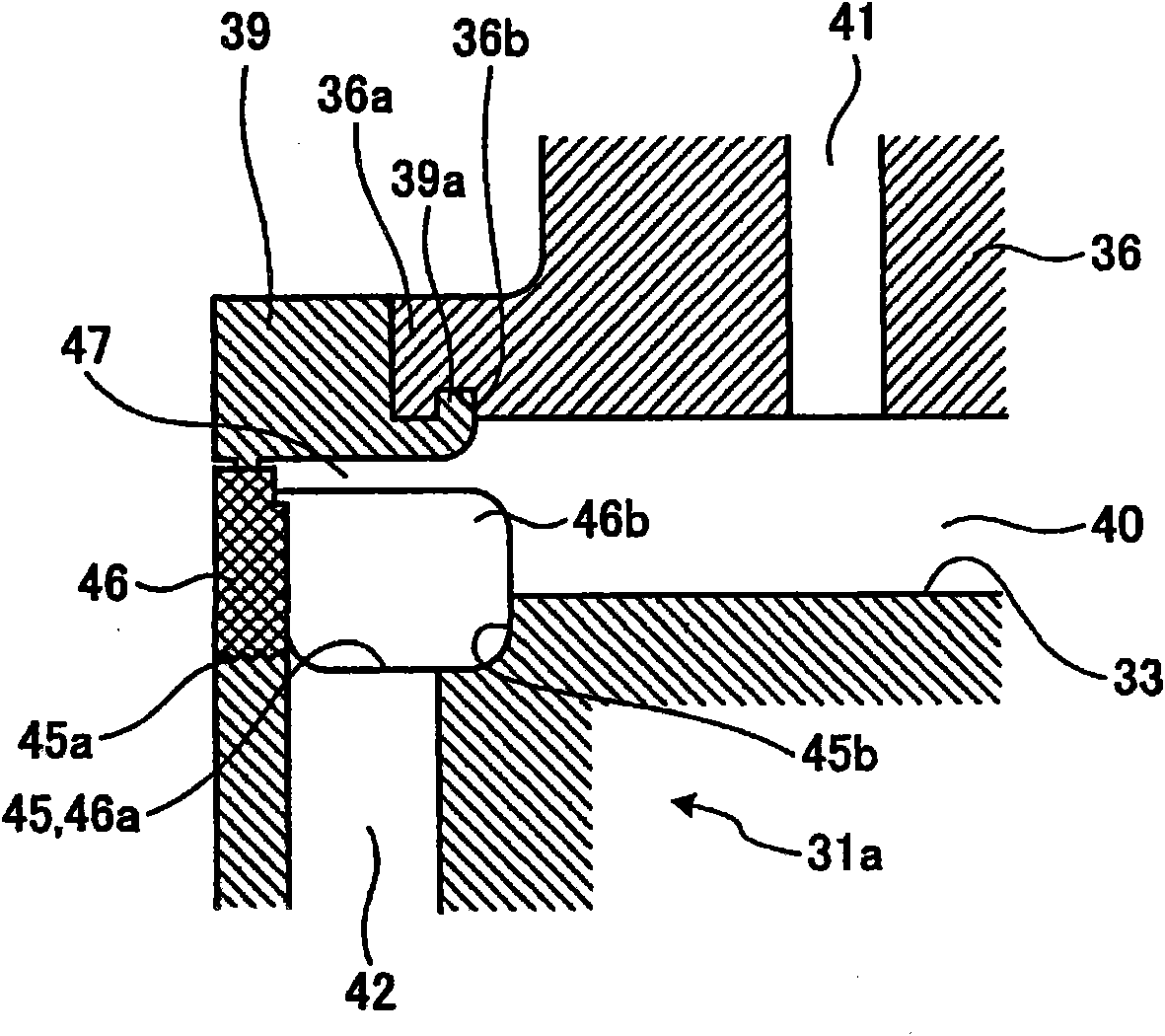

[0051] figure 1 It is a schematic diagram of a turbine upstream part in a gas turbine according to an embodiment of the present invention. figure 2 It is a front view of main parts of the turbine disk of the gas turbine according to the present embodiment. image 3 yes figure 2 Sectional view of III-III. Figure 4 yes figure 2 Sectional view of IV-IV. Figure 5 It is an exploded perspective view of the rotor blade of the gas turbine of this embodiment. Figure 6 It is an explanatory diagram showing the relationship among the diameter, interval, and stress concentration factor of cooling holes. Figure 7 It is a graph showing the stress concentration factor with respect to the diameter and spacing of cooling holes. Figure 8 is a schematic configuration diagram of the gas turbine of this embodiment. Figure 9 is a schematic diagram showing a modified example of the turbine disk of the gas turbine of the present embodiment.

[0052] The gas turbine of this embodiment, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com