Durable return air warming furnace

A kind of heating stove, durable technology, applied in the direction of household stove/stove, lighting and heating equipment, solid heating fuel, etc., can solve the problems of the furnace and the furnace bridge are not smooth, the use of fuel is very limited, and the air intake channel of the furnace is blocked. , to achieve the effect of convenient and reliable opening, full utilization of fuel heat, and simplified use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

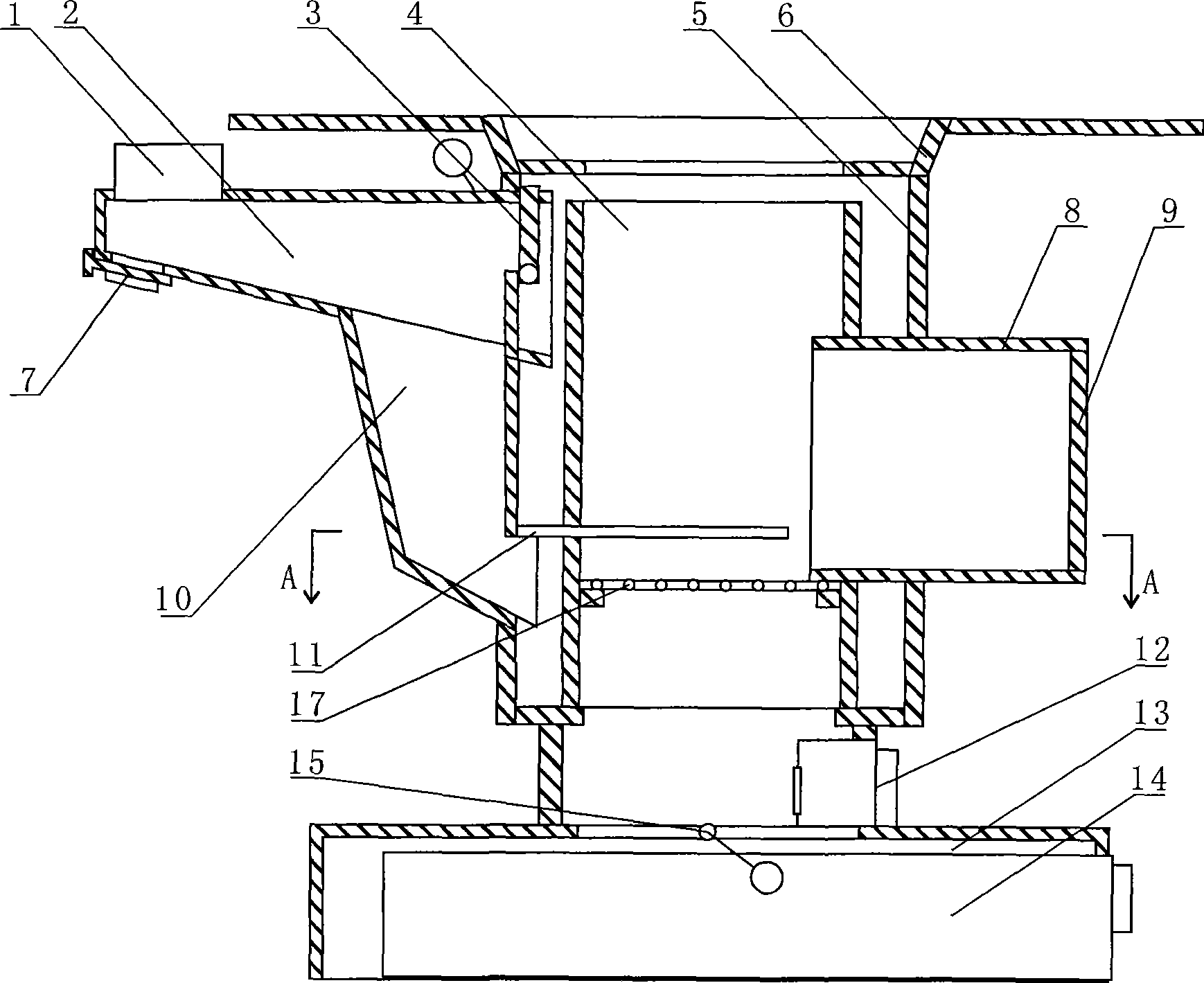

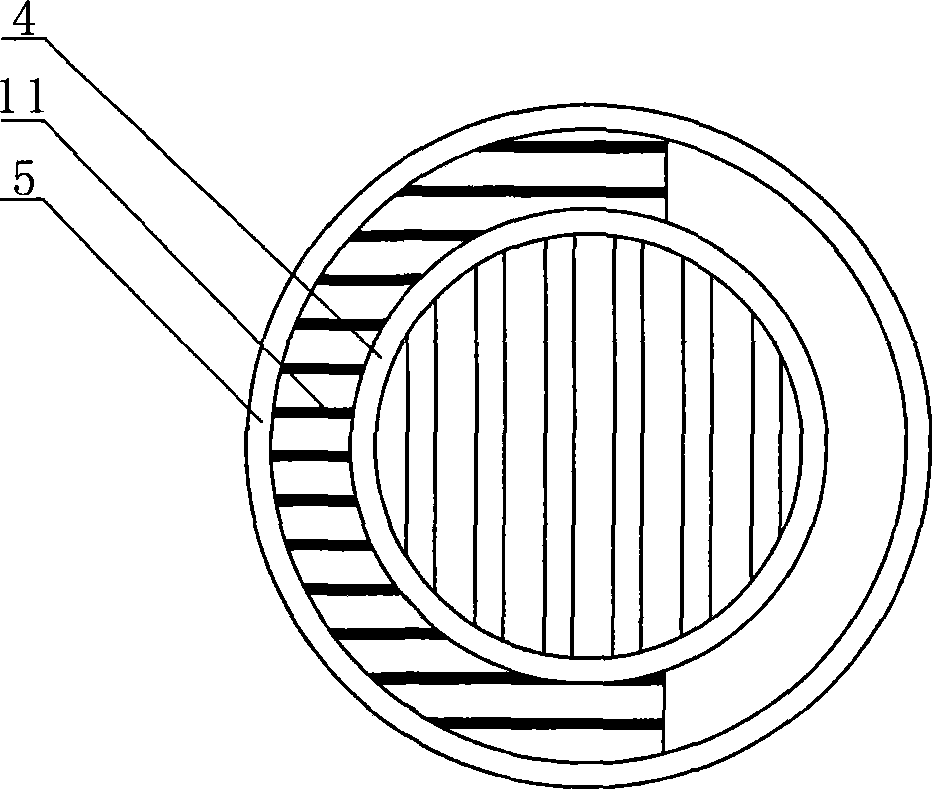

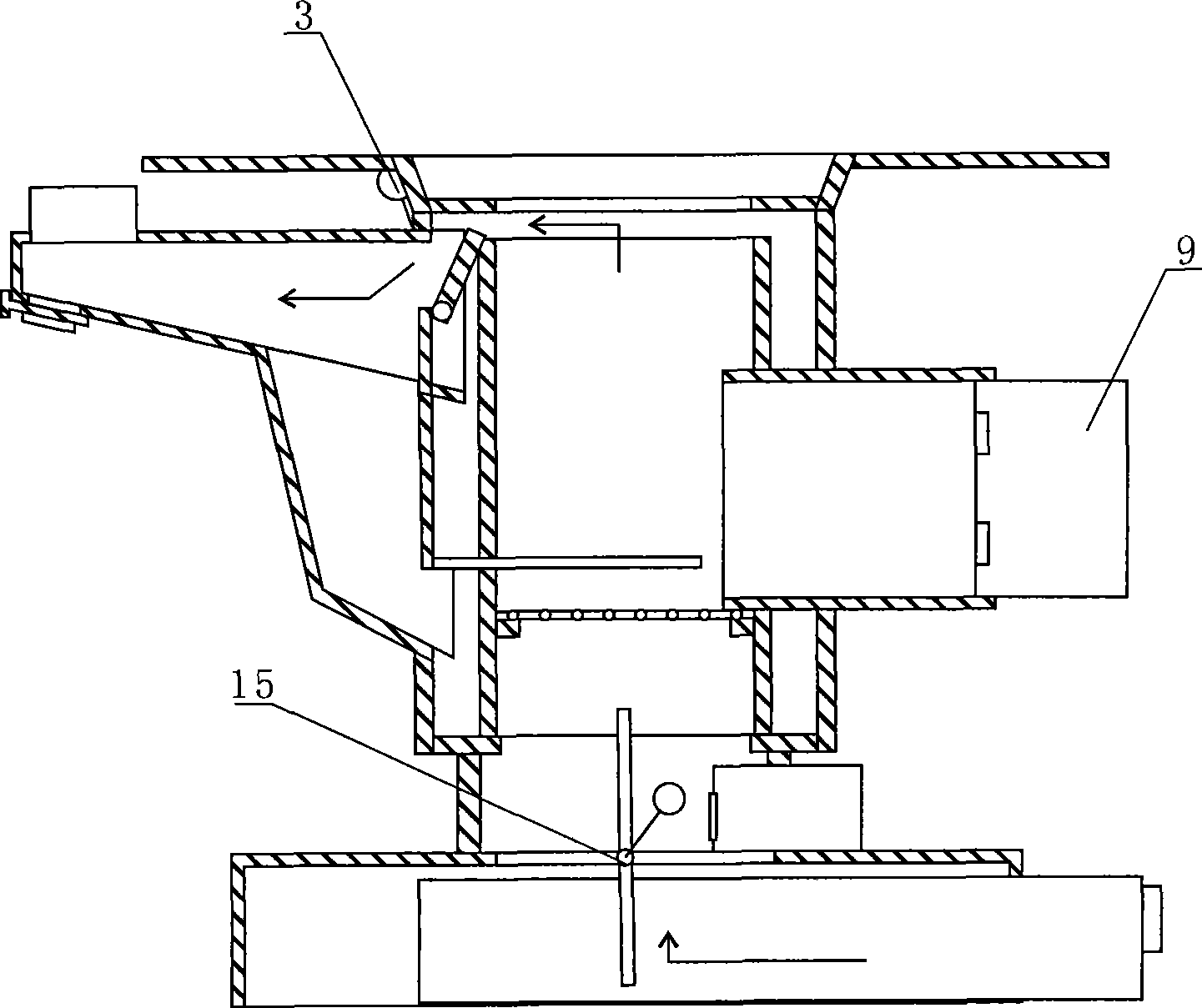

[0018] Such as figure 1 , figure 2 Among them, a durable return air heating furnace includes a furnace body 5, an ignition flue 2 and a tempering flue 10 are installed on one side of the furnace body 5, the ignition flue 2 is connected to the chimney 1, and the feeding port 8 is installed on the furnace body 5 On the other side, a base 13 is installed under the furnace body 5, and the ash hopper 14 is installed in the base 13. It is characterized in that the furnace 4 is movably installed in the furnace body 5, and the middle part between the furnace 4 and the furnace body 5 is close to the tempering The flue 10 is provided with a semi-circular smoke baffle 11, the lower part of the furnace body 5 is provided with a damper 12, and the furnace bridge 17 is installed at three quarters of the lower part of the furnace 4, 0-5 cm away from the lower edge of the feed port 8. An ignition switch 3 is installed in the ignition flue 2 . Furnace hearth 4 is movably installed in body o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com