Overload protective device for strength tension test of structure of thin-wall case of high-speed aerocraft

A high-speed aircraft, tensile test technology, used in the testing of machine/structural components, measuring devices, instruments, etc., can solve instantaneous pressure overload, ceramic or composite thin-walled warheads are expensive, and thin-walled warheads are damaged. Sexual accidents and other problems, to achieve the effect of reliable guarantee of safety, simple structure, convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

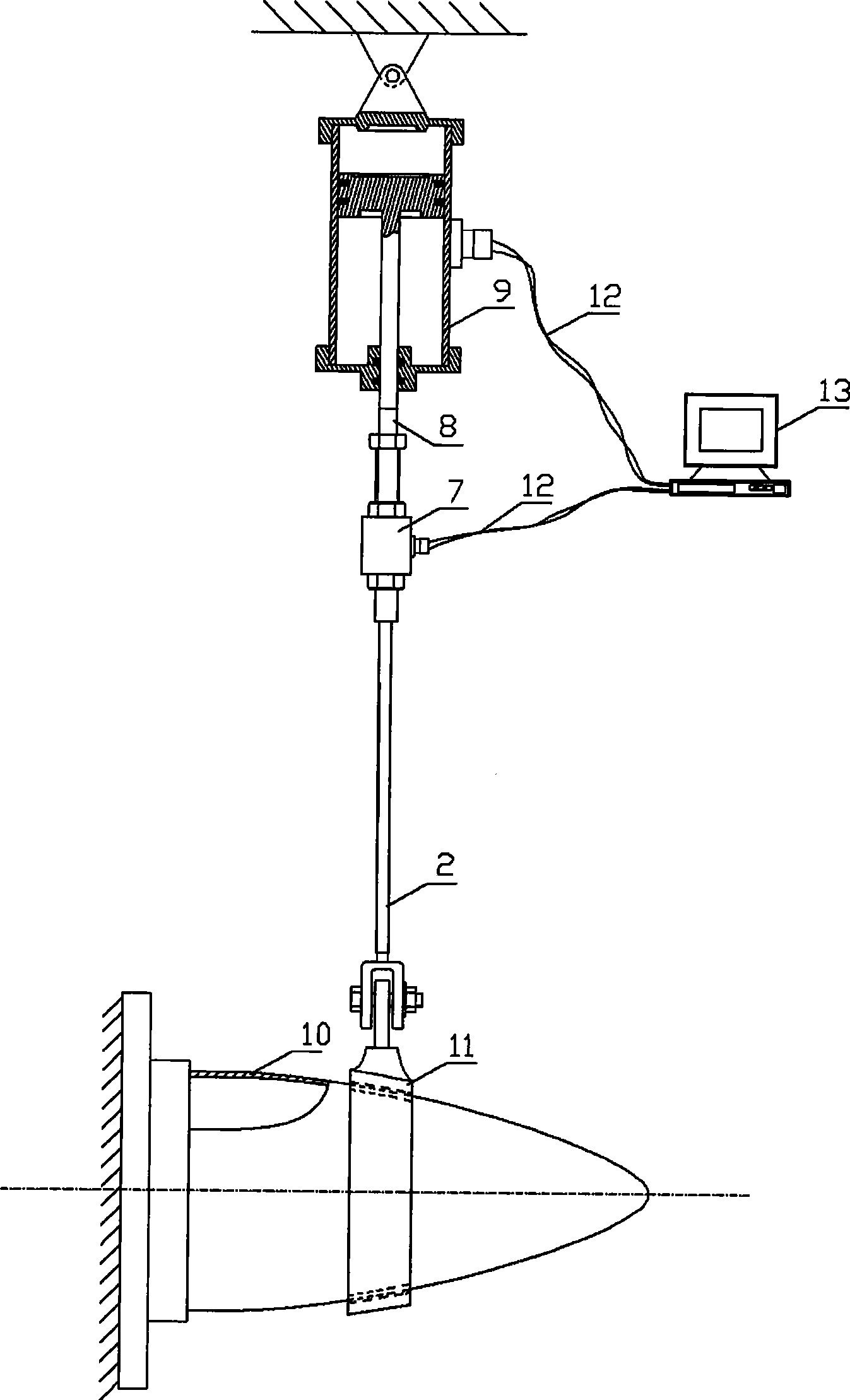

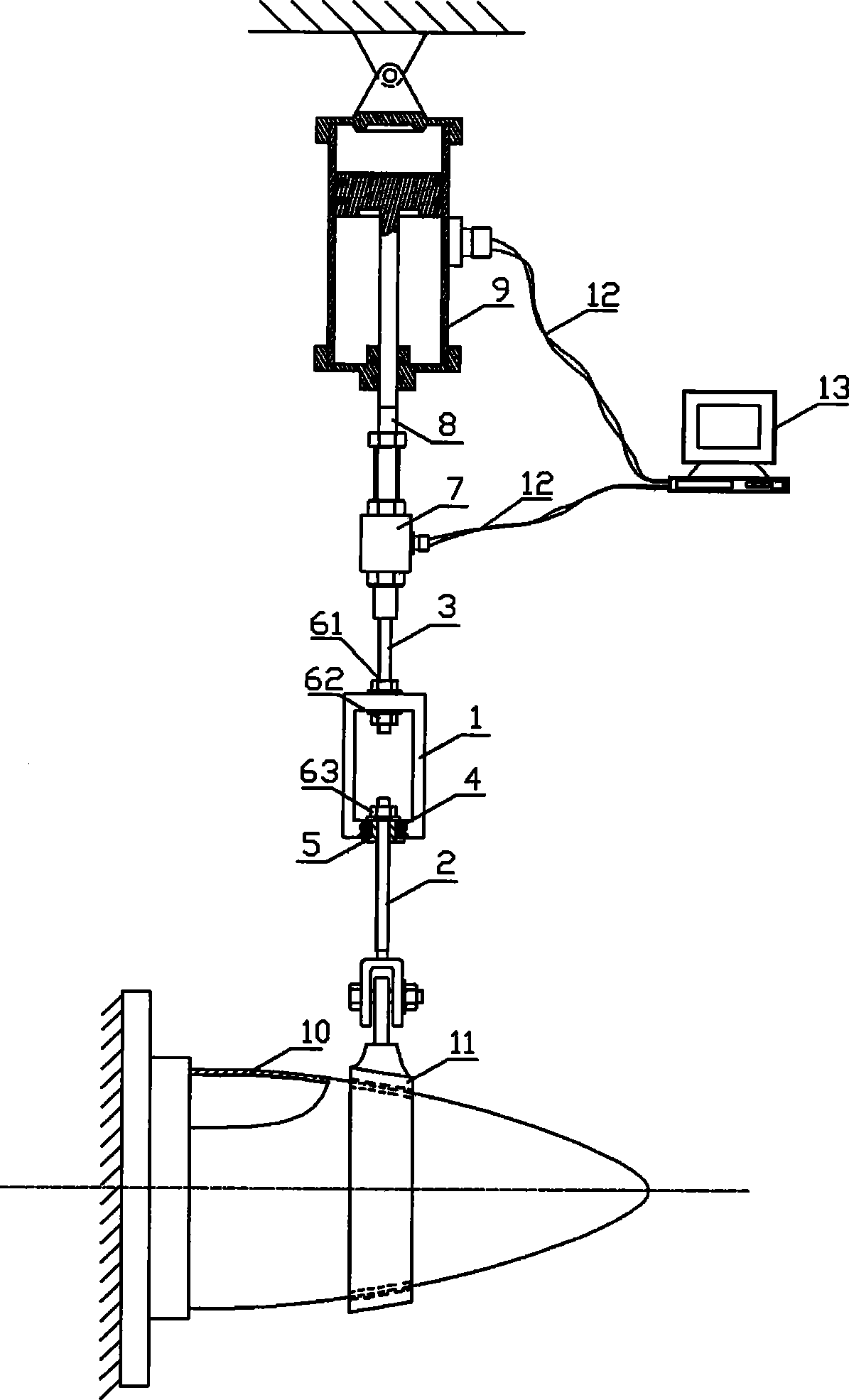

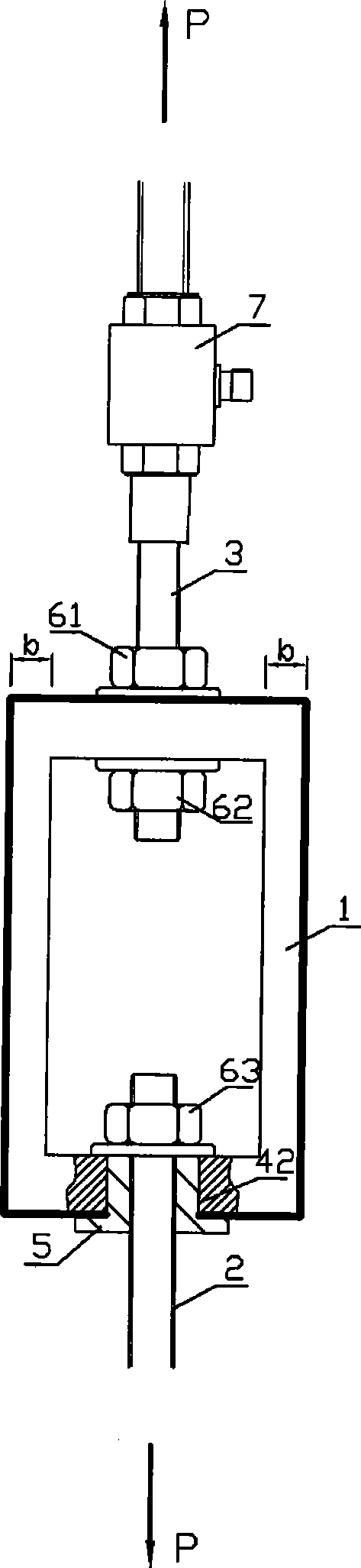

[0031] The main idea of the present invention is to change the two-way fixed connection mode into a one-way (only in the stretching direction) fixed connection loading mode, and a load transition frame is designed and installed. During the loading process, when the force-added shaft of the actuator quickly returns to zero, due to the inertial force, when the force-added shaft of the actuator goes down beyond the zero position, the one-way limit movable connection rod can slide upward freely in the load transition frame, Thereby, the inertial compression load of the afterburner shaft of the actuator is not added to the thin-walled shell test piece of the missile, avoiding the accidental damage of the thin-walled shell test piece of high-speed aircraft such as the expensive missile warhead and projectile due to compression overload and the test fails.

[0032] The above and other technical features and advantages of the present invention will be described in more detail below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com