Process for Damascus

A process method and substrate technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of complex processing and low efficiency, and achieve the effect of improving efficiency and reducing the number of times of development and etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

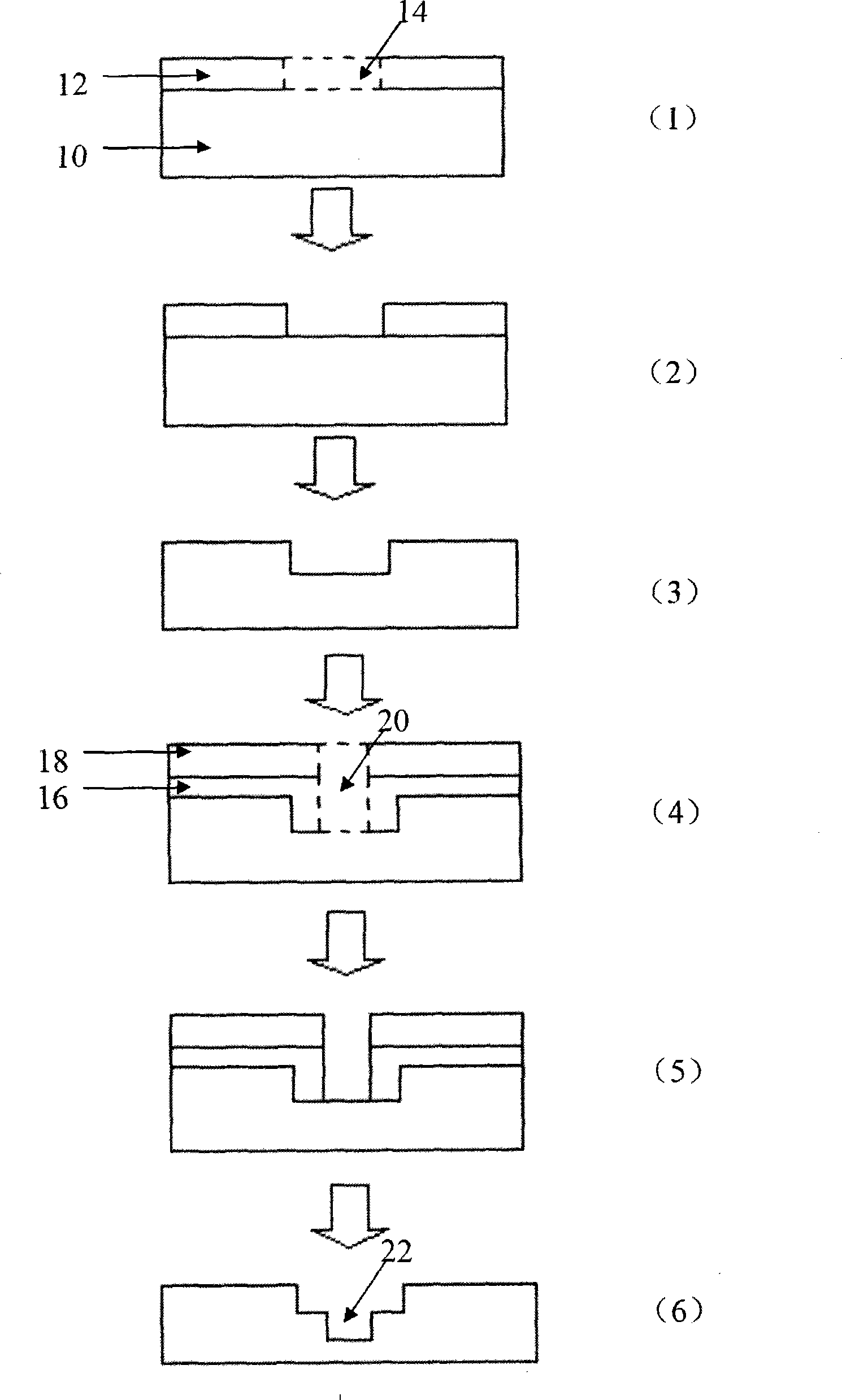

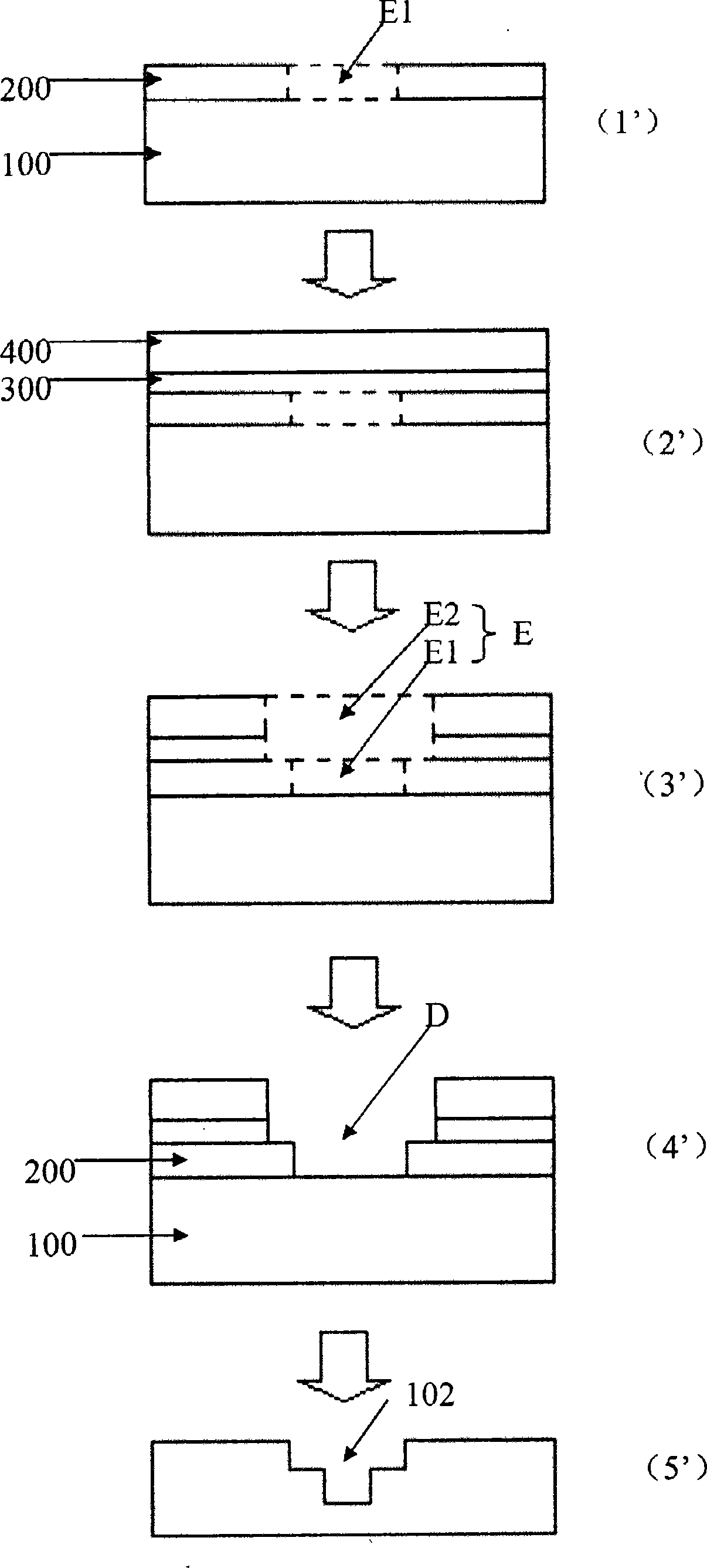

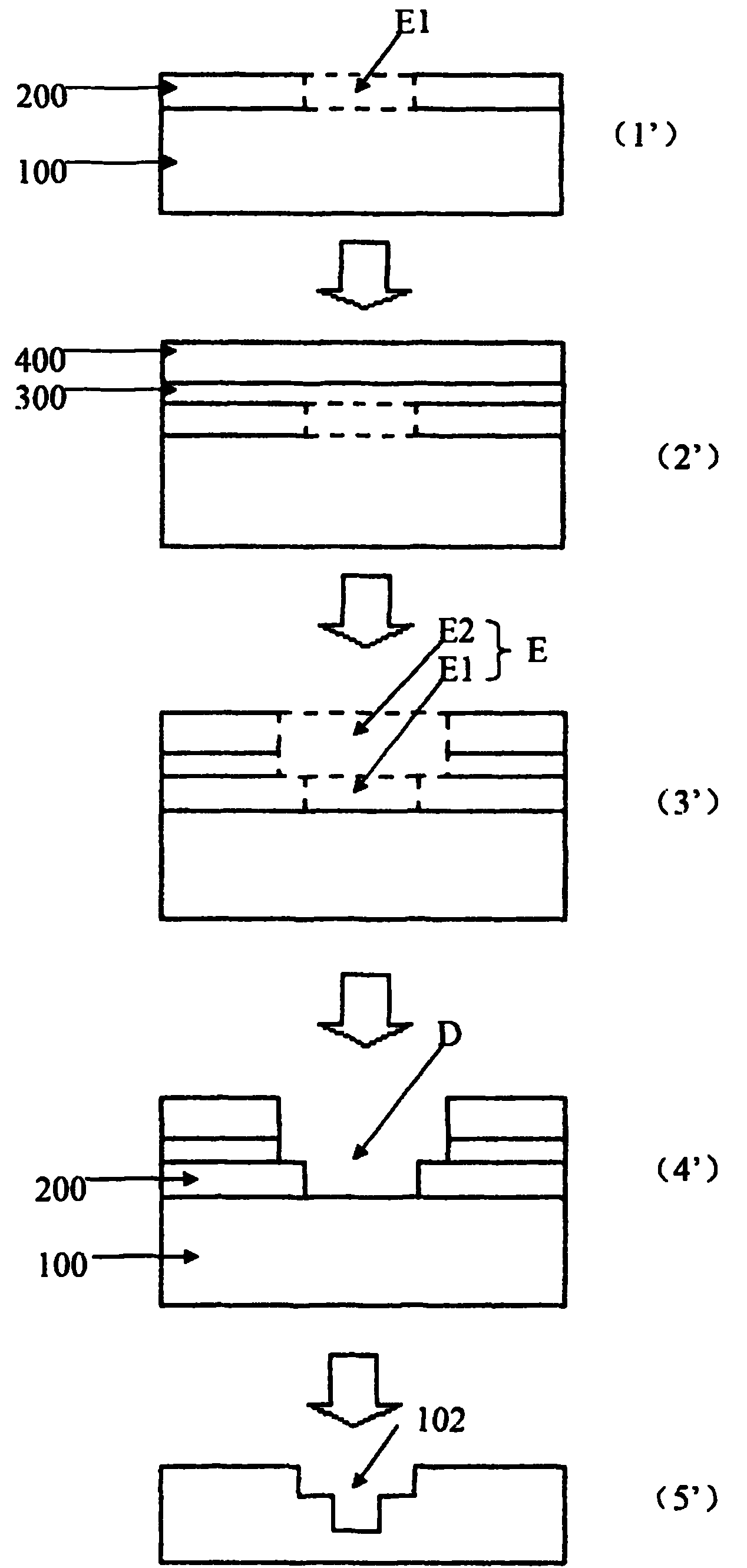

[0022] In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The damascene process method of the present invention can reduce the number of times of development and etching during the formation of the groove on the substrate (or the interlayer via hole on a dielectric layer), and it includes the following steps:

[0024] Continuously performing exposure treatment on a plurality of photoresist layers without developing treatment in between, thereby forming an exposure area;

[0025] performing a developing treatment on the exposed area to obtain a developed area corresponding to the exposed area;

[0026] The base or a dielectric layer is etched through the above-mentioned developing area to form the desired groove or through hole.

[0027] In order to better understand the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com