Solid-state structure comprising a battery and a variable capacitor having a capacitance which is controlled by the state-of charge of the battery

A technology of capacitors and capacitor plates, applied in the direction of variable capacitors, electrolytic capacitors, capacitors that change capacitance mechanically, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

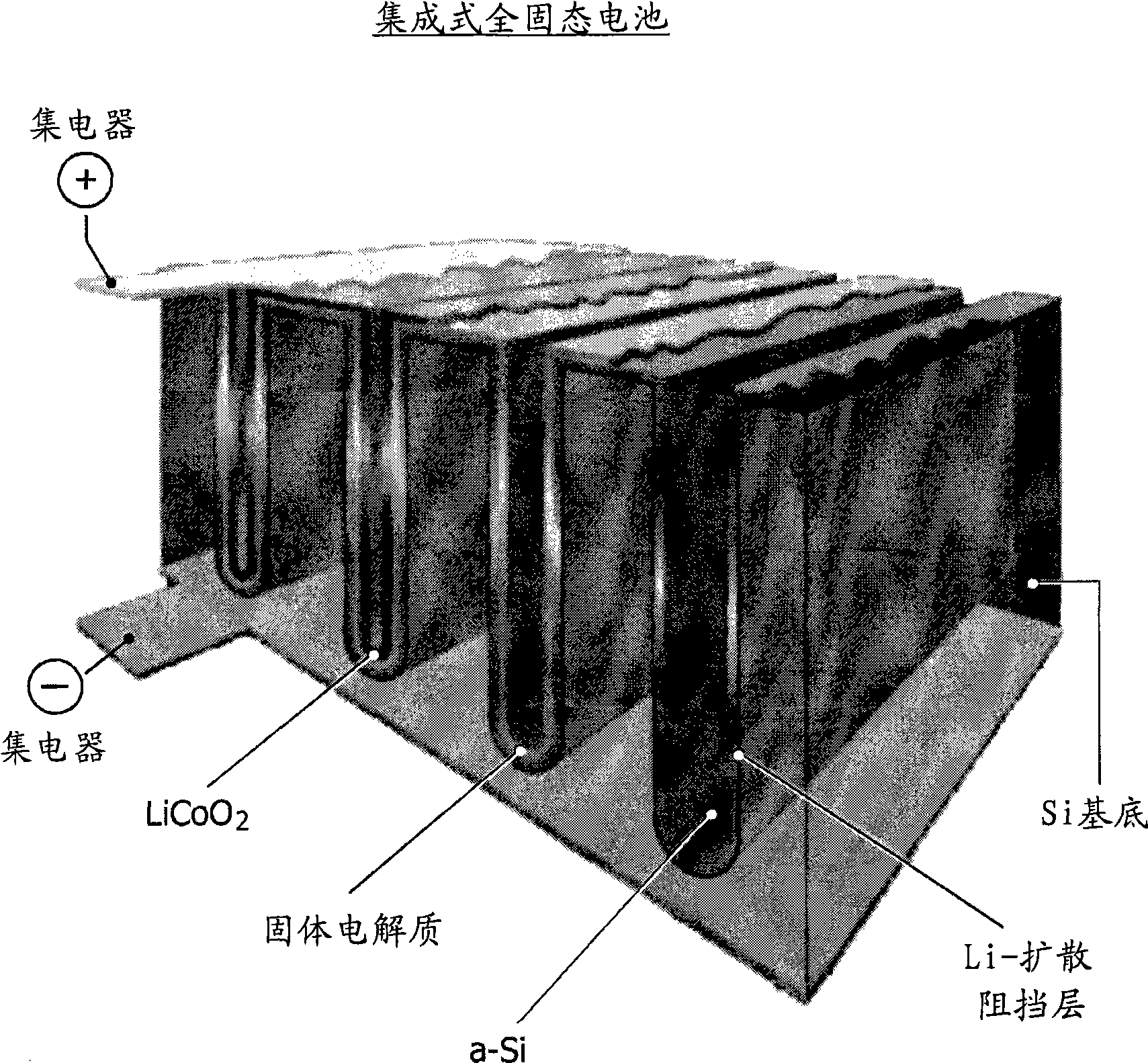

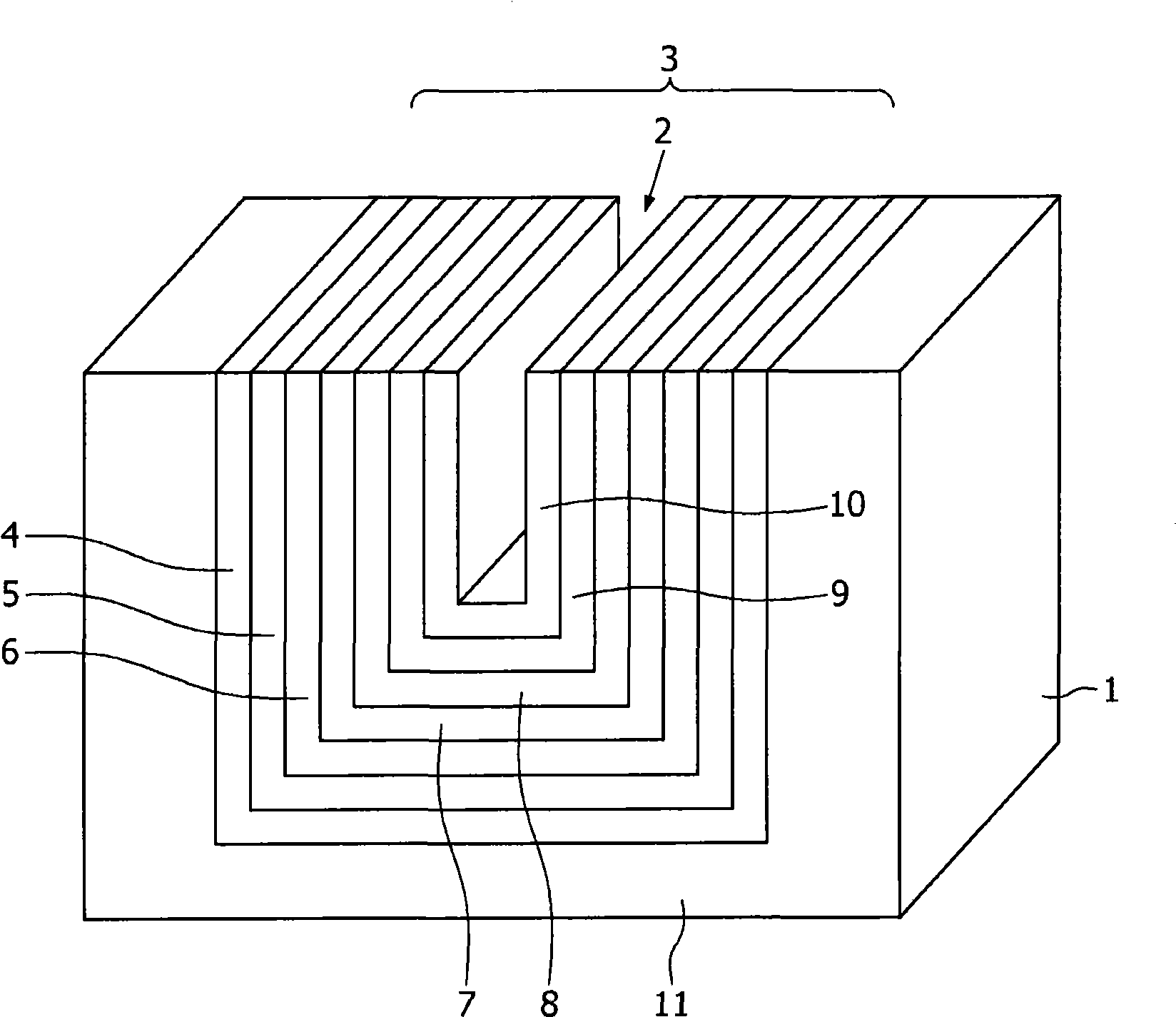

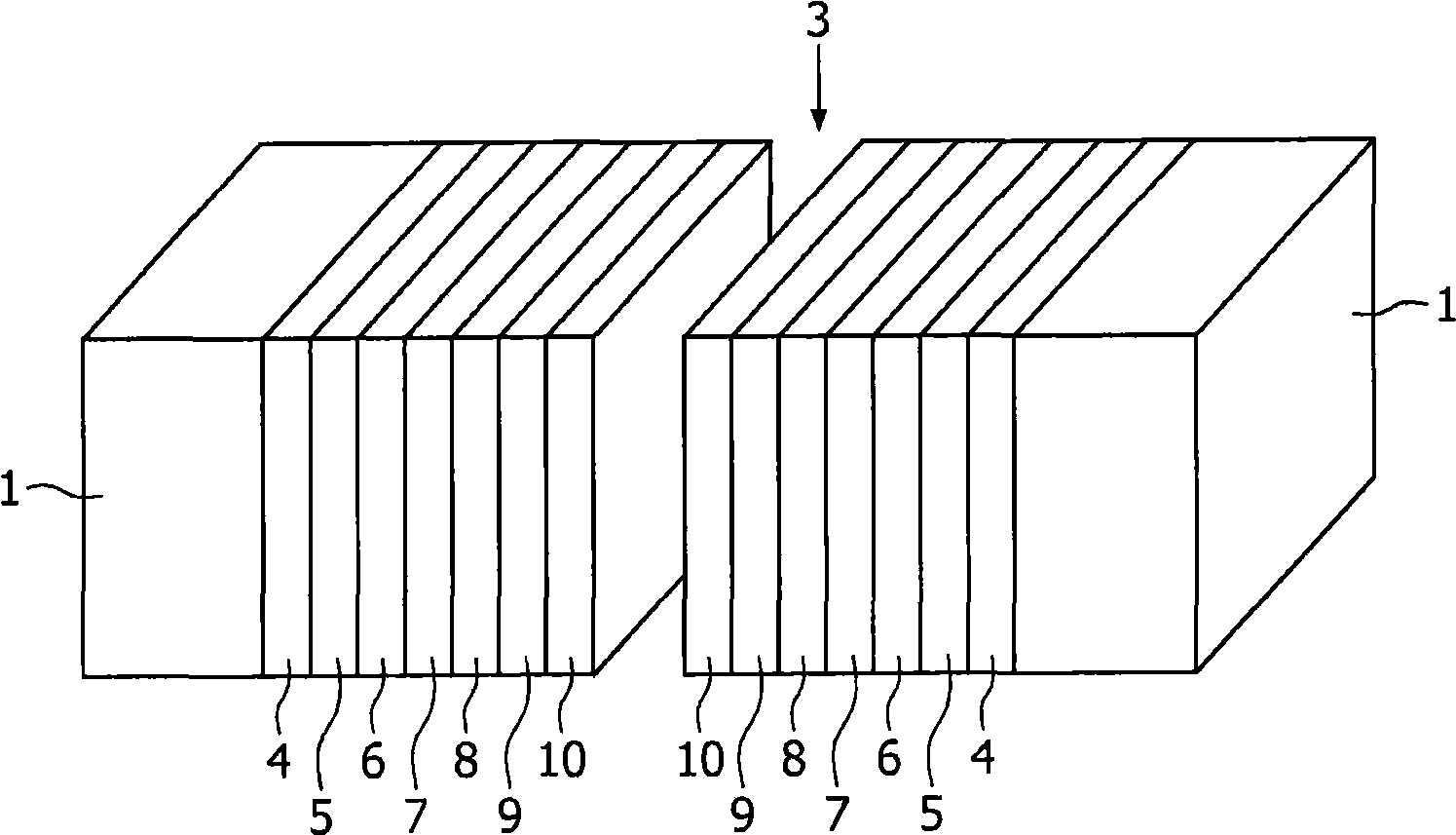

[0042] figure 1 An all-solid-state thin-film battery disclosed in document WO2005 / O27245A2 is shown. Using the deposition and integration techniques described in this prior art document, it is possible to make stacks that can be used to fabricate electrochemically tunable capacitors. The stack is in figure 2 shown in . In this figure there is shown a schematic view of a single trench in a substrate 1 in which a trench 2 is formed in which a cell stack, generally indicated at 3 , is deposited according to the prior art method described above.

[0043] This battery stack 3 applied to a substrate 1 comprises a current collector layer 4 , a cathode layer 5 , a solid electrolyte layer 6 and an anode layer 7 . On top of the anode layer 7 a current collector layer 8 is deposited. On the cell stack 3 thus formed is deposited a dielectric layer 9 on which is located a conductive layer 10 which will serve as a capacitor plate away from the current collector layer 8 . The dielectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com