Three-stage dust chamber structure of spray-type dust collection tower

A technology for dust removal towers and dust removal chambers, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of long dust removal pipes, easy blockage of dust removal devices, and high prices, and achieves good dust removal efficiency and dust removal. Efficiency No clogging, quick removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

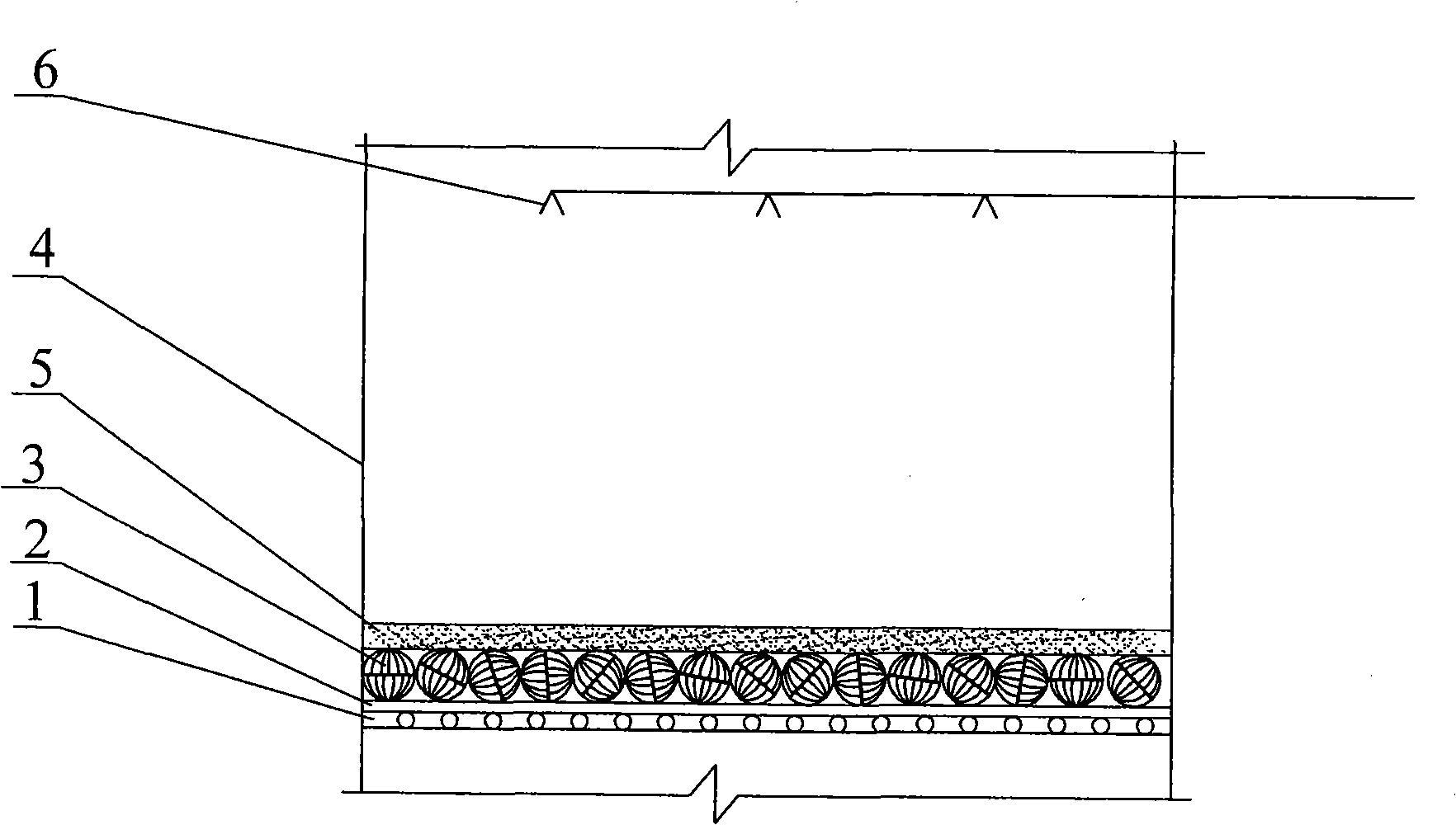

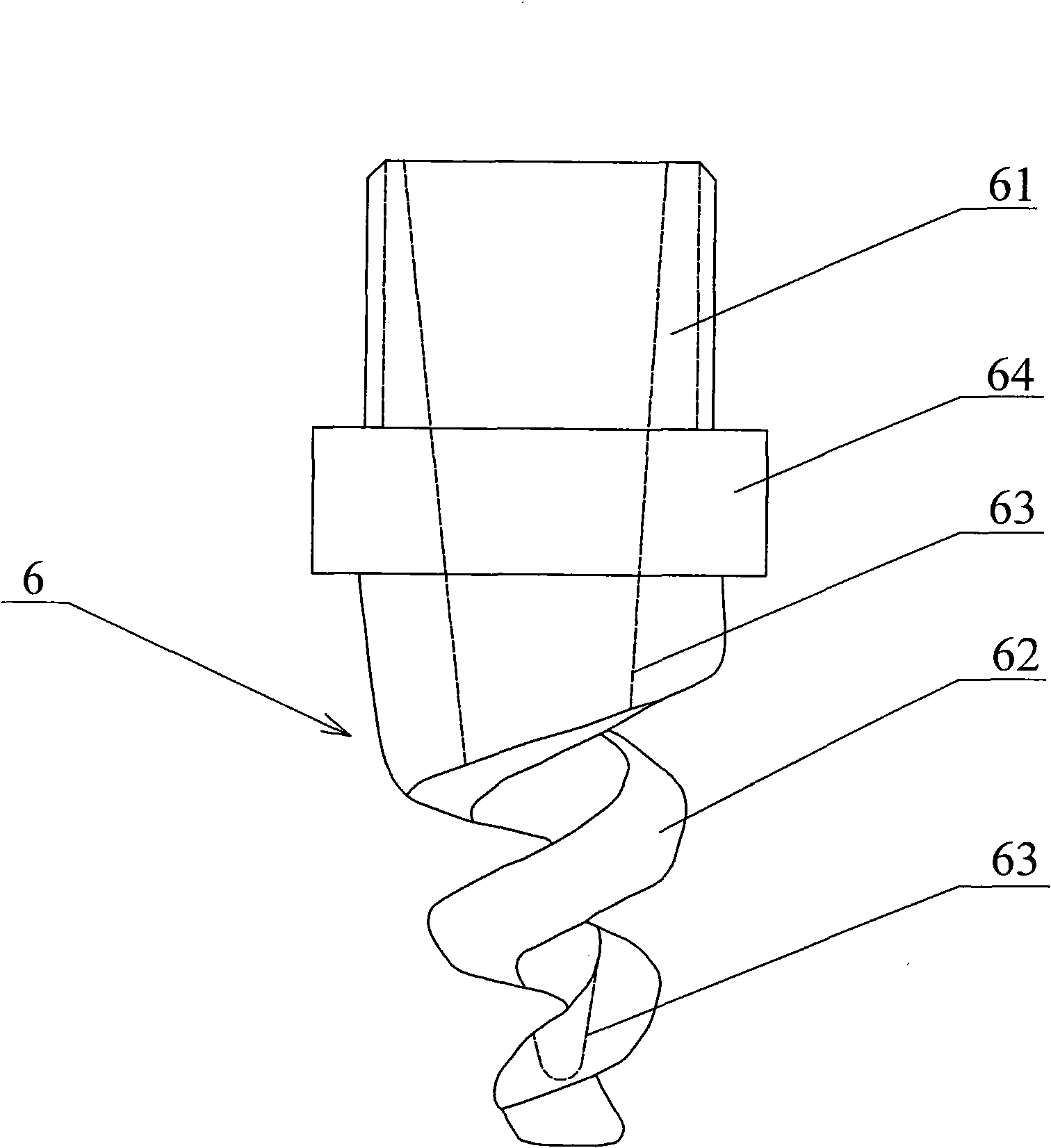

[0016] As shown in the figure: the structure of the three-stage dedusting room of the spray dedusting tower, which includes a support frame 1 fixed on the inner wall of the dedusting tower 4, the support frame 1 is covered with a corrosion-resistant net layer 2, and the corrosion-resistant net layer 2, the dust removal carrier ball 3 is laid, and the dust removal carrier ball 3 is covered with a spongy filter layer 5, and several spray heads 6 are erected in the dust removal tower 1 above the spongy filter layer 5.

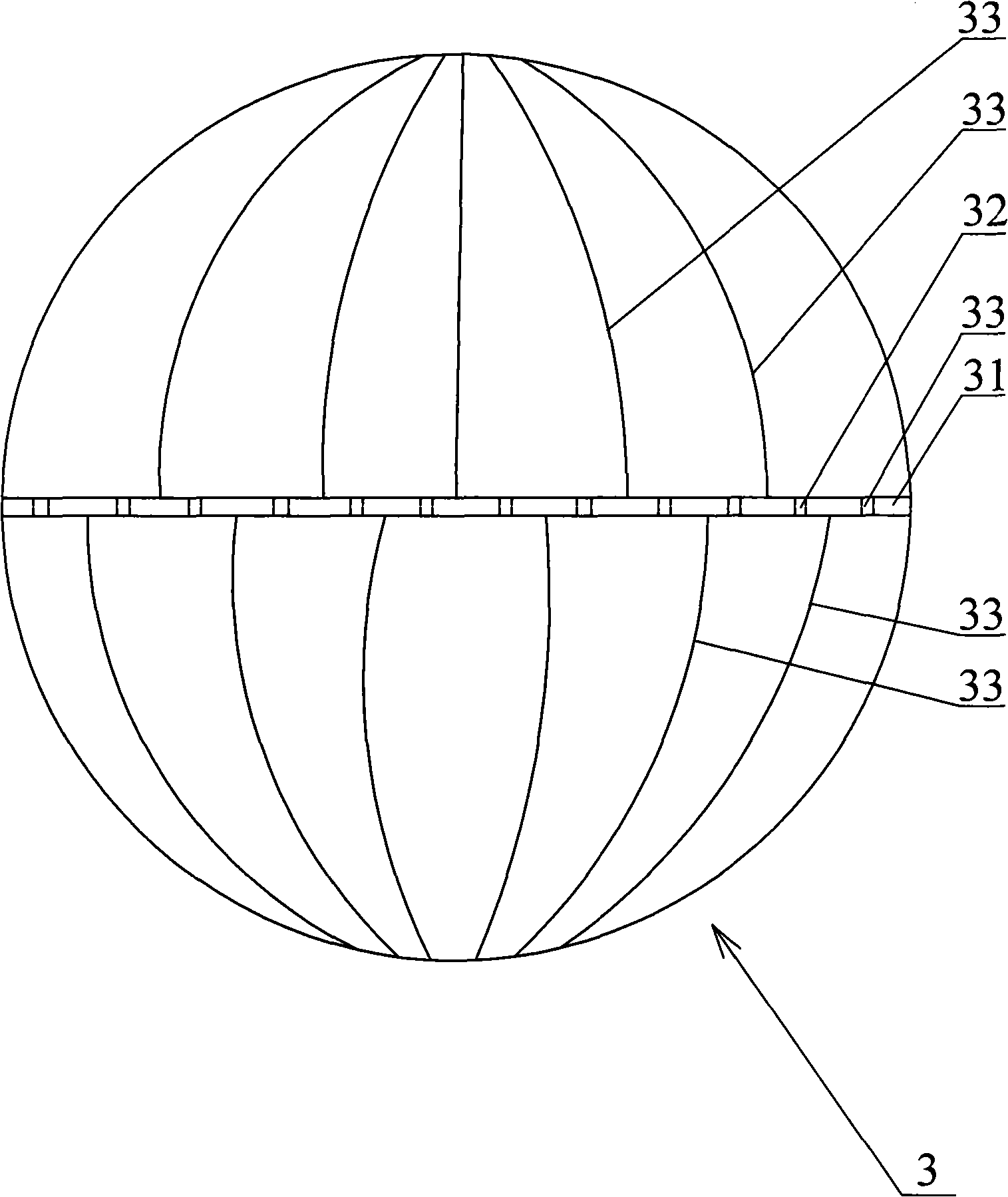

[0017] Described dedusting carrier ball 3 comprises the ventilation hole 32 that offers on the mounting plate 31, and several blades 33 are fixed on the upper and lower surfaces of the mounting plate 31, and the blades 33 roots on the upper and lower surfaces of the same mounting plate 31 are misplaced, and the air holes 32 The axis has a point of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com