Bubble generator in air floatation rotary-splitting coupling technique

A technology of bubble generator and process, which is applied in mixing methods, chemical instruments and methods, and dissolution, etc. It can solve the problems that the time for the bubbles to fully combine with the mixed liquid is difficult to be guaranteed, the bubbles are not uniform and fine, and the air flotation effect is not good. , to achieve the effect of simple structure, good backwashing effect and good air flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

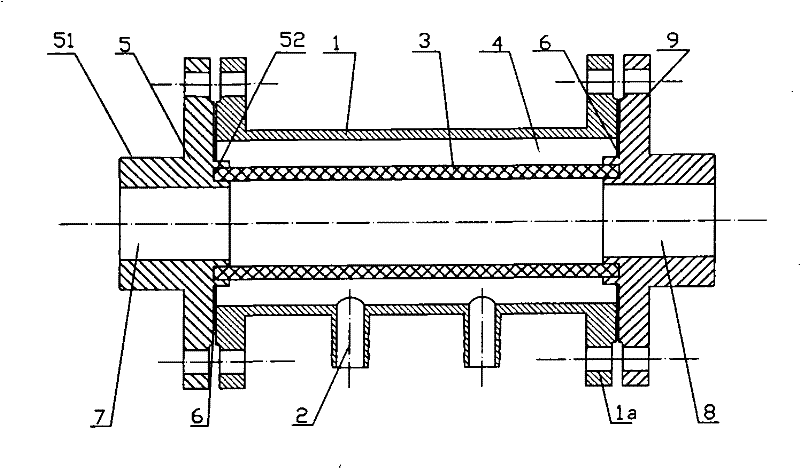

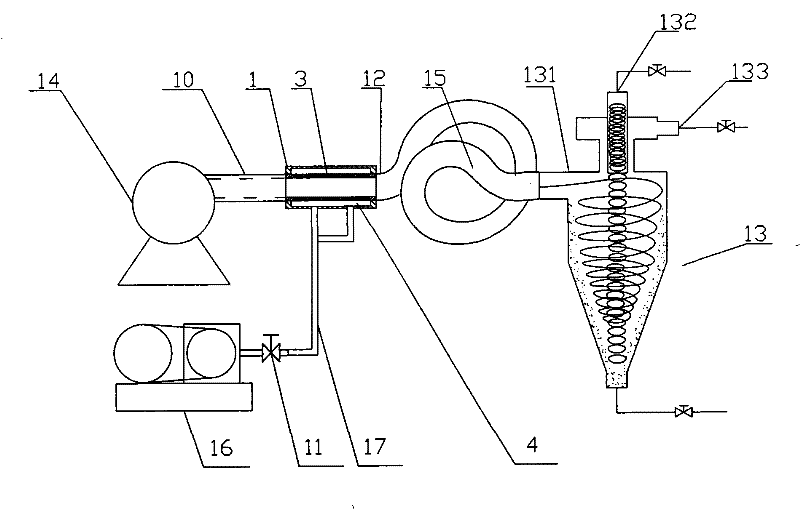

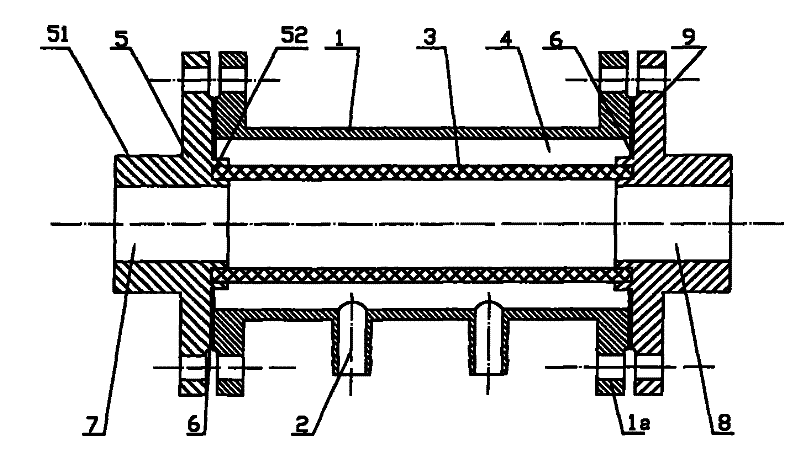

[0014] Such as figure 1 Shown: the bubble generator in the air flotation cyclone separation coupling separation process provided by the present invention, which includes an outer tube 1, a microporous membrane tube 3, the outer tube 1 is provided with an inflation interface 2, and the microporous membrane tube 3 is inserted into the outer tube 1 and sealed with the outer tube 1, an annular cavity 4 is formed between the microporous membrane tube 3 and the outer tube 1, which communicates with the lumen of the microporous membrane tube 3 through the micropores on the wall of the microporous membrane tube , the charging port 2 communicates with the annular cavity 4 .

[0015] The sealed connection structure between the microporous membrane tube 3 and the outer tube 1 is: comprise two pipe joints 5, which include a section of pipe, the pipeline is opposite to the microporous membrane tube 3 and both pipe diameters are equivalent, the pipe joint 5 and The nozzle end face of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com