Automatic scissors apparatus of eletricity stranded wire

A shearing device and stranding technology, applied in shearing devices, shearing machines, presses, etc., can solve the problems of easy regrinding of blades, incompetence, short service life of blades, etc., and achieve easy regrinding and versatility of blades. Large, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

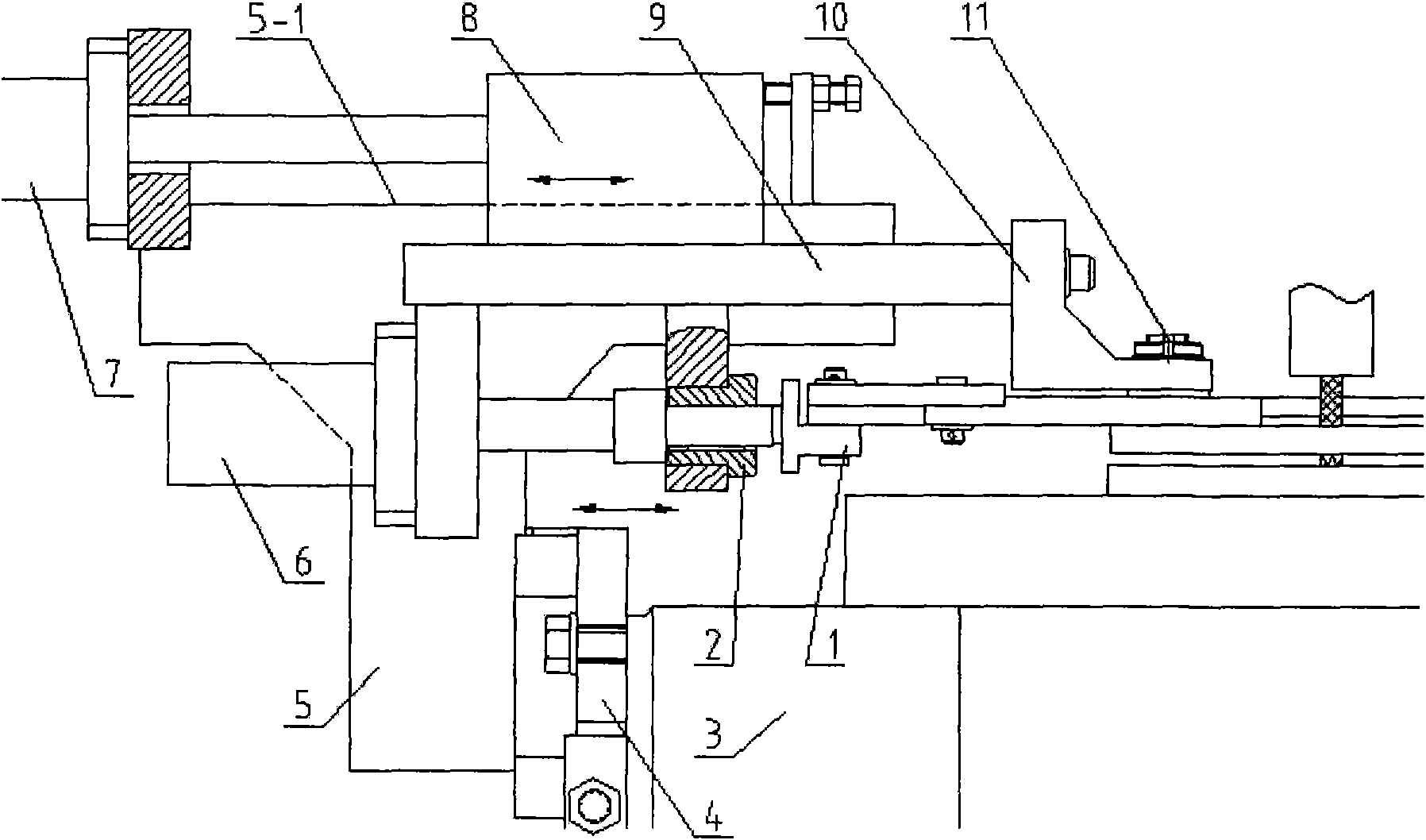

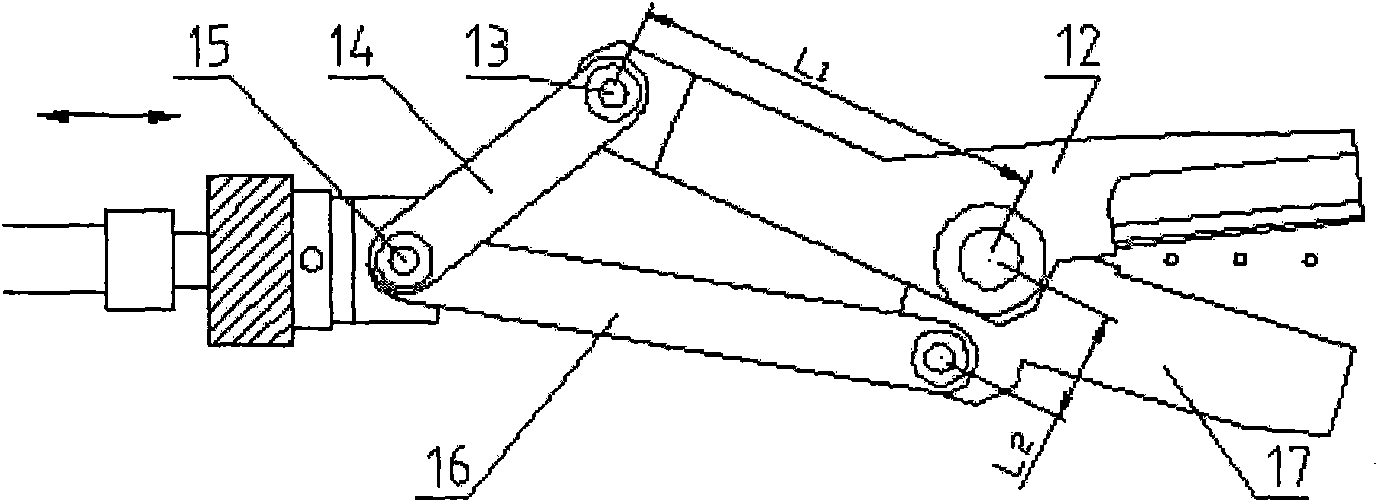

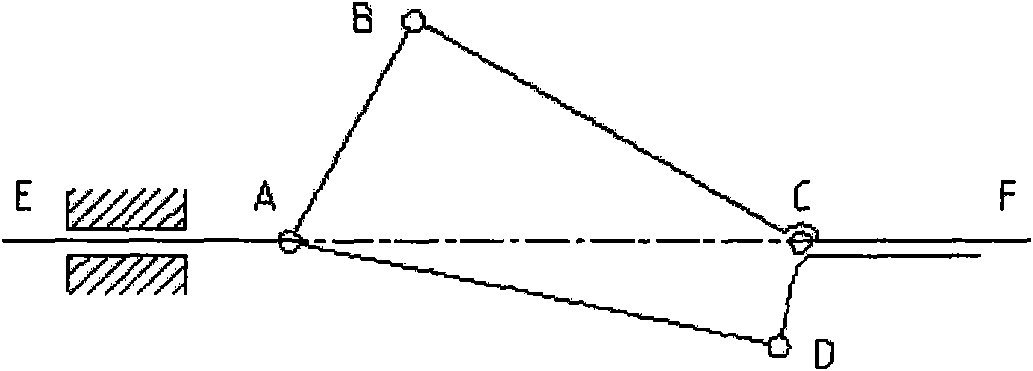

[0026] refer to figure 1 , the electric twisted wire automatic scissors device includes a forming machine base 3, a rectangular transition plate 4 is set on the left side wall of the forming machine base 3, the transition plate 4 can change its position horizontally back and forth on the side wall plane, and the transition plate 4 is provided with The T-shaped bracket 5 that can do vertical movement, the T-shaped bracket 5 is composed of two T-shaped plates symmetrically distributed, the upper part of the T-shaped bracket 5 is processed with a bracket guide rail 5-1, and the left end of the bracket guide rail 5-1 is provided with a drive for sending shears in place The device sends the shear cylinder 7 and the shearing device arranged on it. The piston rod of the shear cylinder 7 is connected with the slide plate 8. The lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com