Electric welding machine

A welding machine and main circuit technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as wasting power and affecting the life of electric welding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

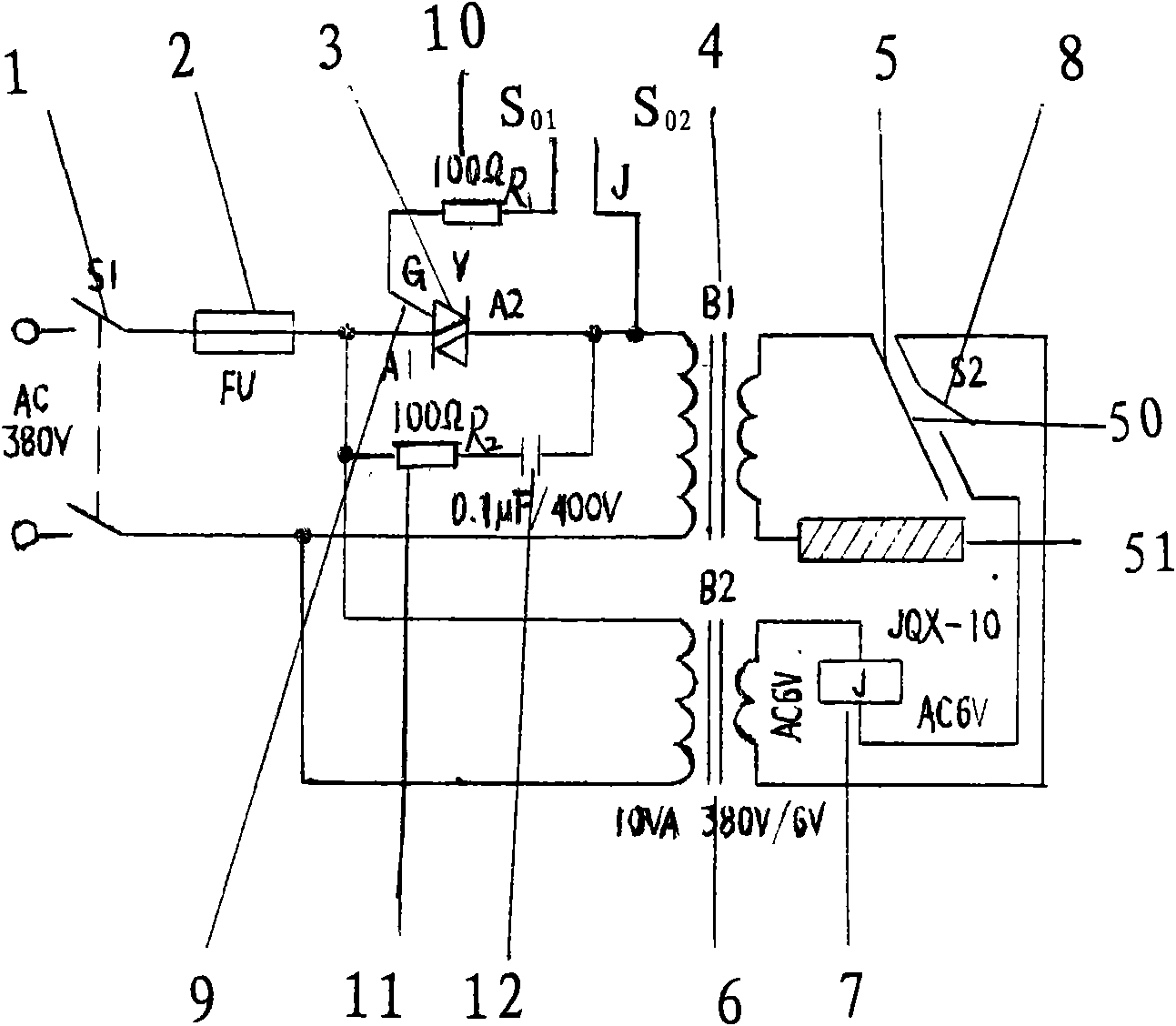

[0008] The present invention is described in detail below in conjunction with accompanying drawing: the circuit control of the present invention is mainly made up of main circuit and control circuit, and main circuit comprises power switch S 1 1. Fuse FU2, triac V3, small transformer B 1 4. Electric welding machine 5, etc.; the control circuit includes a small transformer B 2 6. Relay 7. Micro switch S 2 8. The trigger control pole G9 of the bidirectional thyristor and the current limiting resistor R 1 10 and contact S 01 , S 02 Bypass resistor R 2 11. Capacitor C12, etc.; power switch S 1 1. Connect to 380V AC power supply, fuse FU2 in the FireWire branch device, the outlet of fuse FU2 is connected to A of bidirectional thyristor V3 1 The terminals are connected, and the trigger control pole G9 of the bidirectional thyristor V3 is connected to a current-limiting resistor R 1 10, then connect its contact S 01 , while other contacts S 02 with the other end of the triac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com