Dual-axis driving device

A dual-axis drive and drive mechanism technology, which is applied to drive devices, metal processing mechanical parts, metal processing equipment, etc., can solve problems such as breakage, short circuit breakage, damage to electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

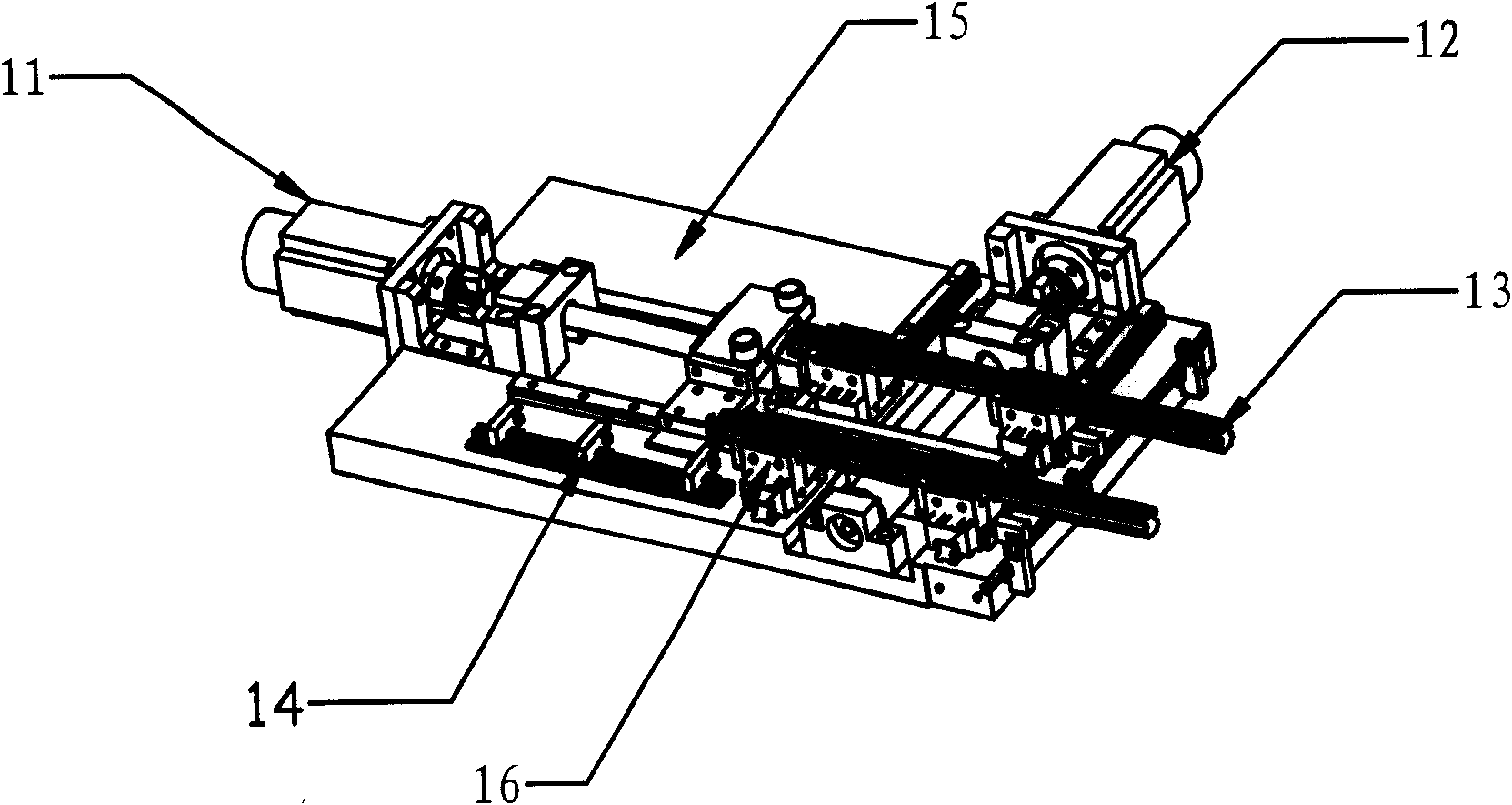

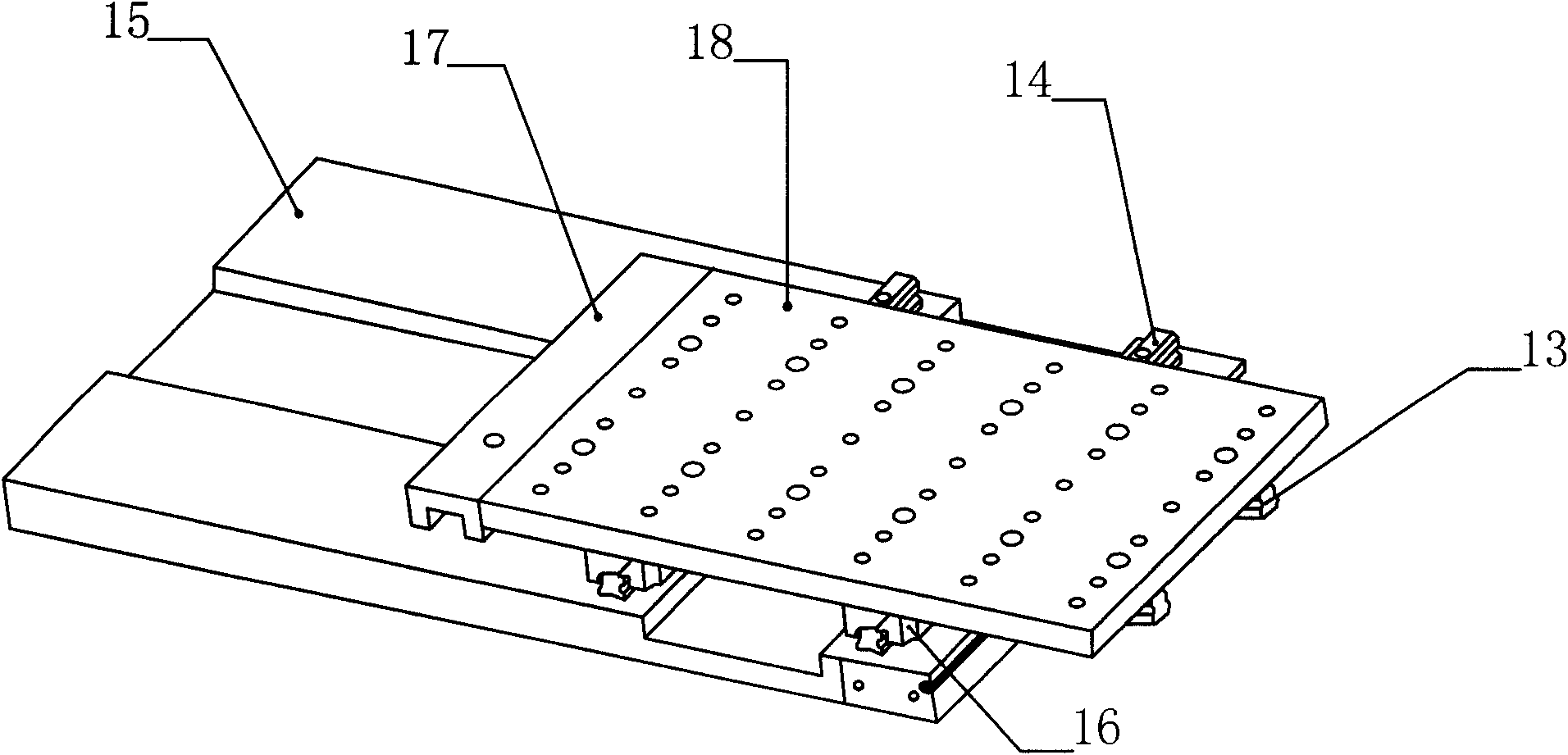

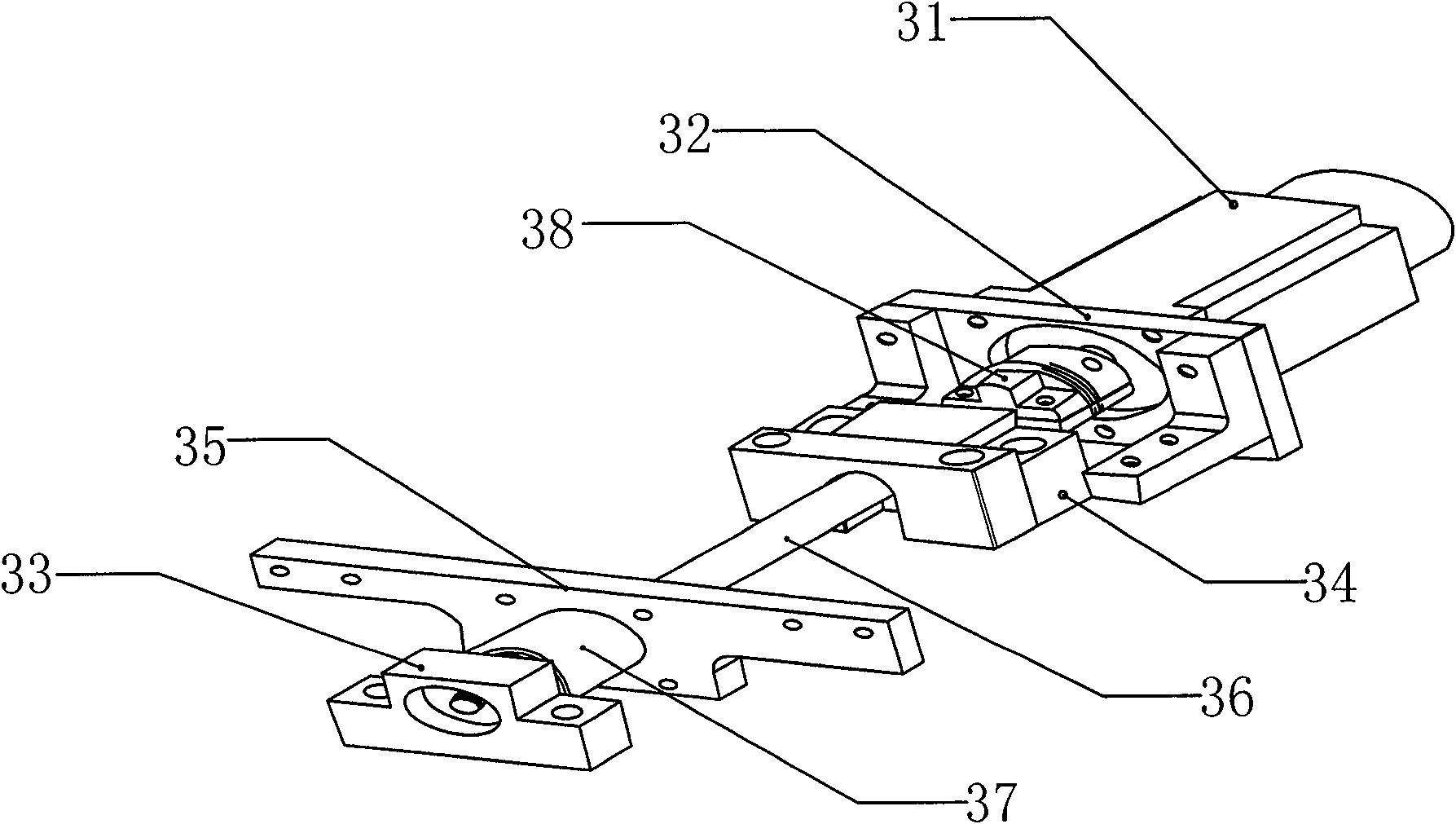

[0015] Such as figure 1 , 2 The embodiment of the present invention shown shows that the first driving mechanism 12 and the second driving mechanism 11 are respectively fixed on the base plate 15, and the directions are perpendicular to each other. The driving directions of the two linear guide rails are consistent, and there are two sliders on each of the lower linear guide rails 14. The first driving mechanism 12 is connected with the slider on the lower linear guide rail 14 through the connecting plate, thereby driving the sliders to move; the two upper linear guide rails 13 are fixed on the working On the platform 18, the direction is perpendicular to the direction of the lower linear guide rail 14, and each of the upper linear guide rails 13 has two sliders, the sliders on the upper linear guide rail 13 correspond to the sliders on the lower linear guide rail 14, and are connected to each other as a whole The slider group 16, the connecting plate 17 and the working platf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap