Automatic current-collecting cart for tyre type container gantry crane

A gantry crane and container technology, which is applied to elevators, transportation and packaging in buildings, can solve the problems of large error reliability, low operation efficiency, loose structure, etc., to prevent interference, high operation efficiency and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

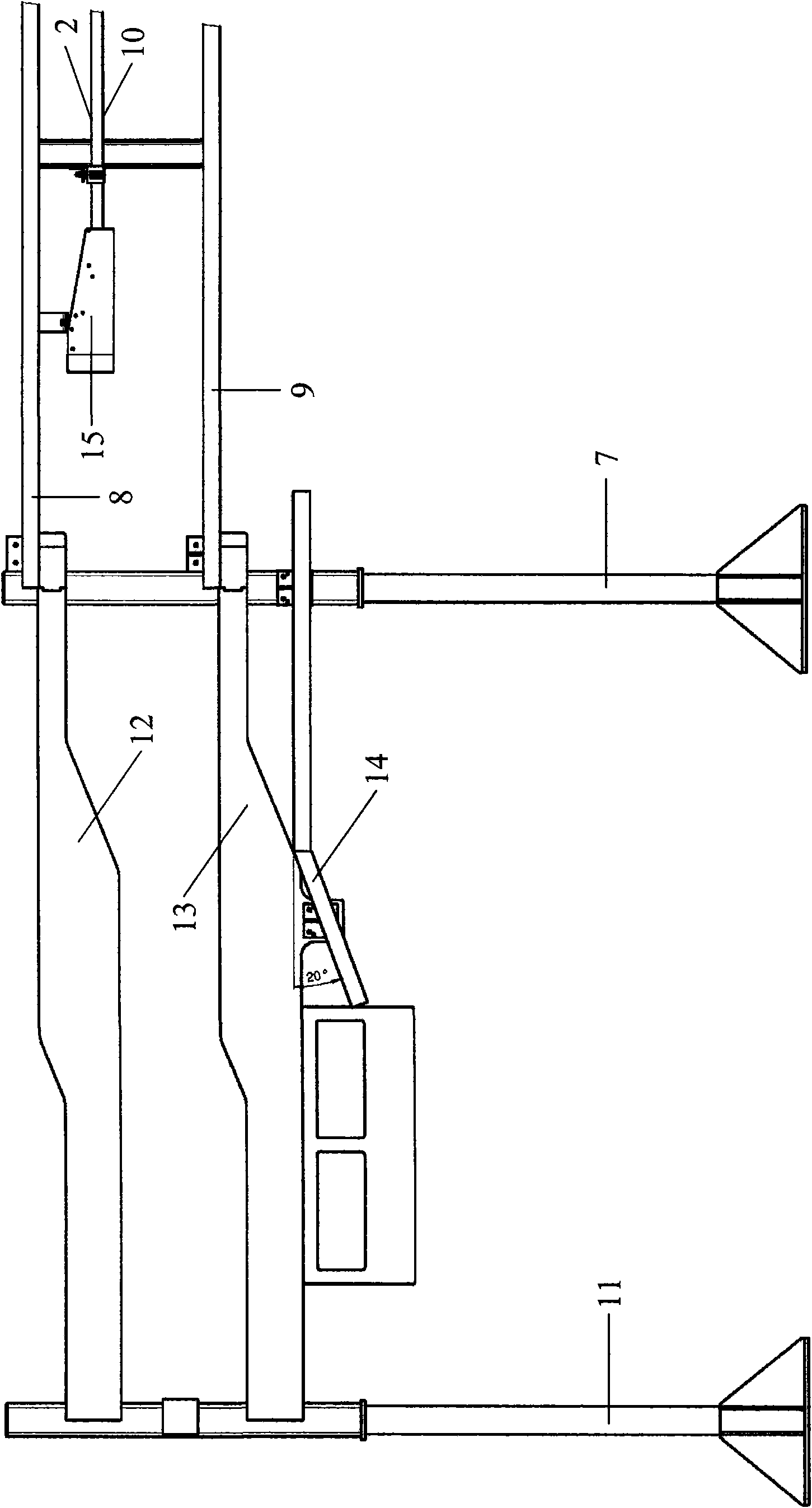

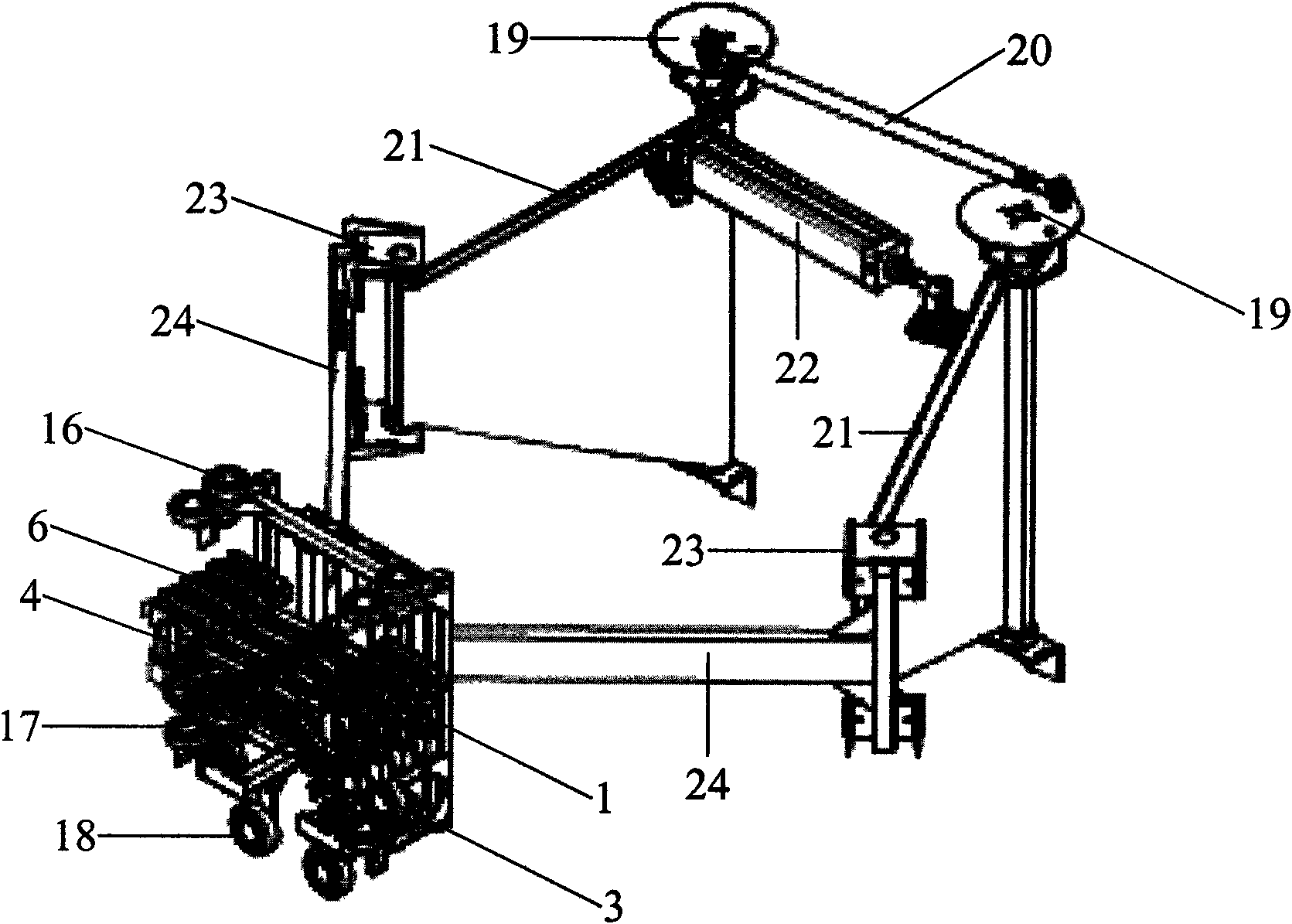

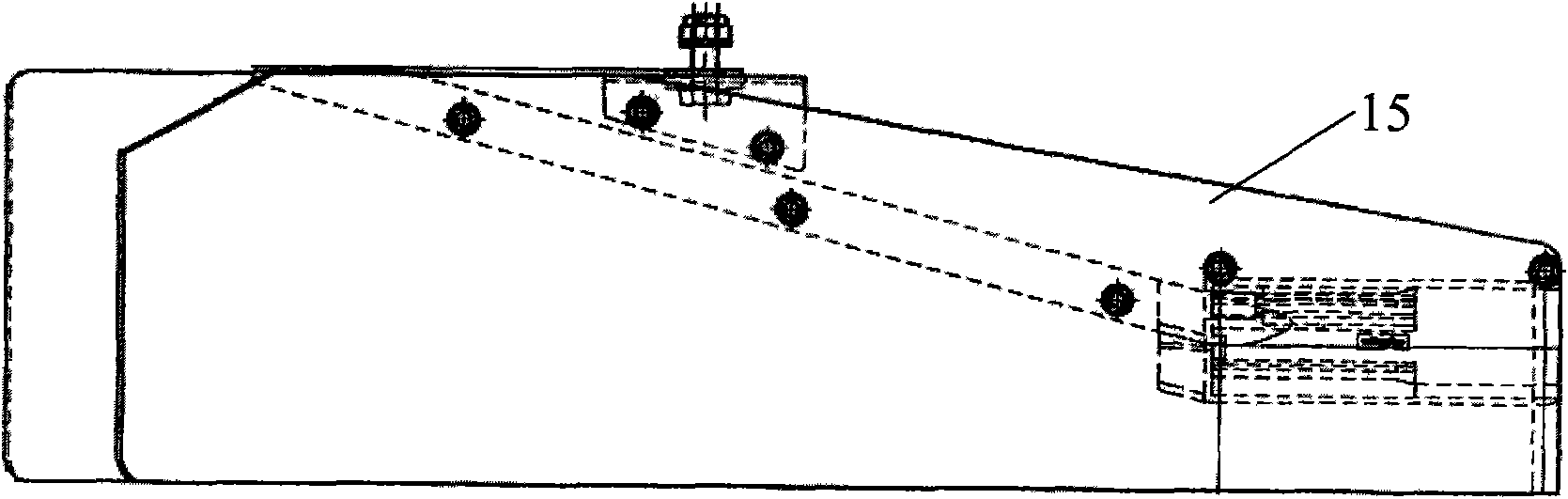

[0031] An automatic current collecting trolley for a tire-type container gantry crane, comprising a traveling trolley 1 and a trolley line 2, a stand 11, an upper backing plate 12, a lower backing plate 13, a guide plate 14, and a guide opening 15, such as figure 1 and figure 2 As shown, the two columns 7 of the gantry frame of the gantry crane are connected by the upper rail groove 8, the bracket 10 and the lower rail groove 9, and the upper rail groove 8, the bracket 10 and the lower rail groove 9 are all placed horizontally and from top to bottom Arranged in sequence, the trolley line 2 is fixed on the bracket 10, and the trolley line 2 is respectively connected to the phase line and the neutral line of the mains power system. The lower part of the trolley 1 is equipped with a travel wheel set 3, and the travel wheel set 3 is on the lower guide rail groove 9. Rolling, fixed collector 4 on the upper part of traveling trolley 1, collector 4 is connected to power supply throu...

Embodiment 2

[0038] In order to enhance the safety and accuracy when taking electricity, limit switch 25, leaning on board indicator light 26, power contactor 27 and carbon brush indicator light 28 can also be increased, as Figure 5 As shown, a limit switch 25 is respectively installed on the upper and lower four corners of the traveling trolley 1, wherein the moving contacts of the upper two limit switches 25 are closed after the upper guide wheel group 16 contacts the upper backing plate 12, and the lower two limit switches 25 are closed. The moving closing contact of limit switch 25 is closed after lower guide wheel group 17 contacts lower backing plate 13, and when the moving closing contact of limit switch 25 is all closed, backing plate indicator light 26 is luminous. Such as Figure 6 As shown, the moving contacts of the power contactor 27 are connected in series on the phase line. When the carbon brushes 6 are all in contact with the trolley line 2, that is, when the moving contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com