Chemical mechanical polishing solution

A chemical machinery and polishing liquid technology, applied in polishing compositions, other chemical processes, chemical instruments and methods, etc., can solve the problem of uncommon surface friction coefficient, and achieve the effect of reducing surface friction coefficient and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

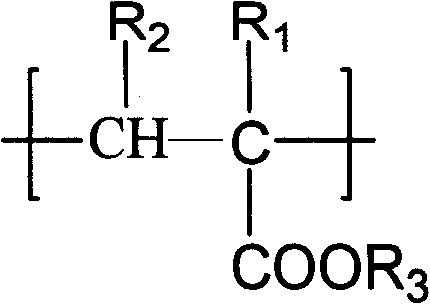

Method used

Image

Examples

Embodiment 1~34

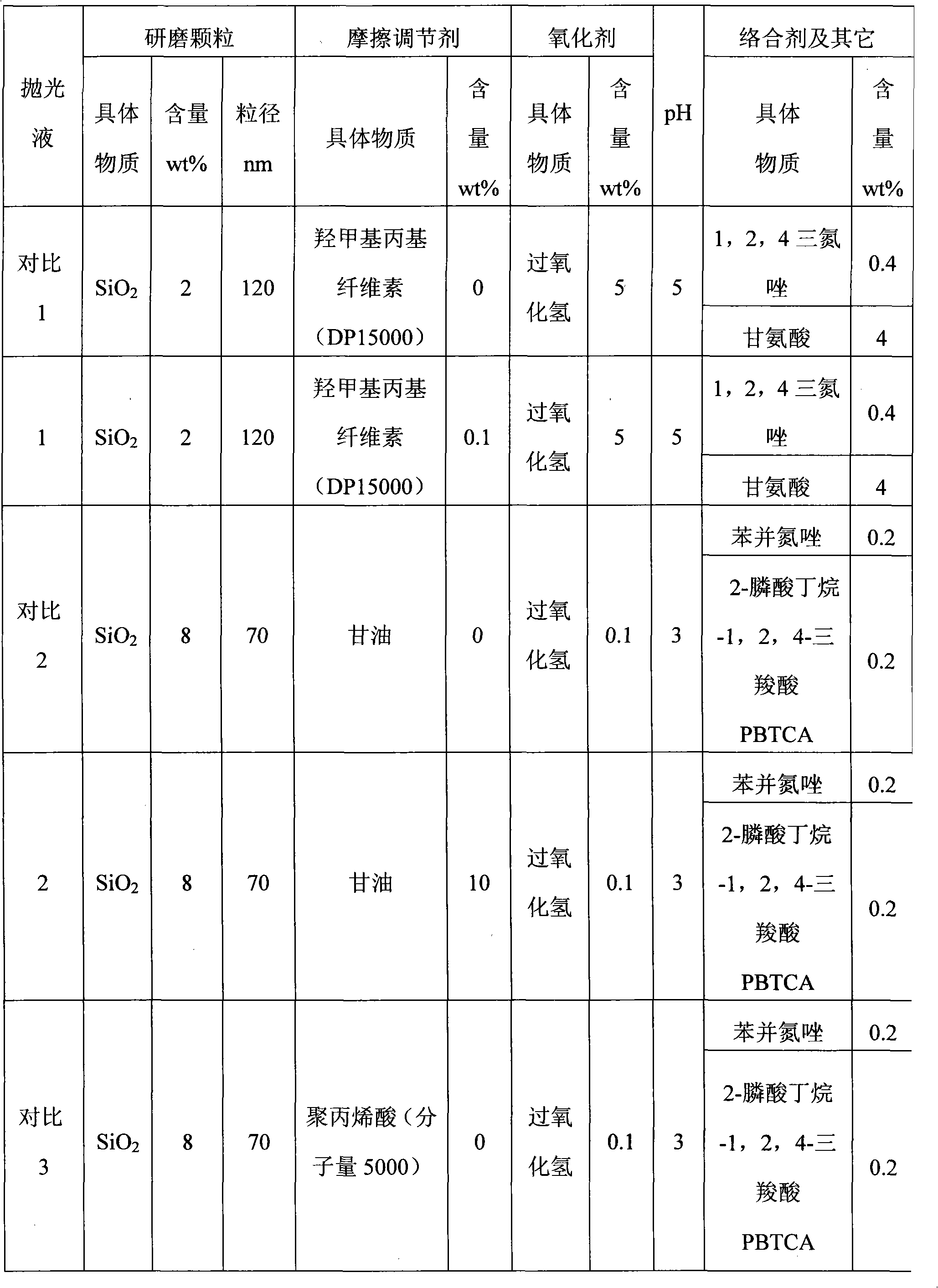

[0026] Table 1 shows the examples 1 to 34 of the chemical mechanical polishing liquid of the present invention. According to the formula in the table, the ingredients are mixed uniformly, deionized water is the balance, and finally a pH adjuster (20% KOH or dilute HNO 3 , Choose according to the needs of pH value) Adjust to the required pH value, continue to stir to a uniform fluid, and stand still for 30 minutes to obtain various chemical mechanical polishing liquids.

[0027] Table 1 Examples 1 to 34 of the chemical mechanical polishing liquid of the present invention

[0028] Throw

[0029]

[0030]

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com