Process for the preparation of laundry soap bars with improved storage stability

A soap bar and stabilizer technology, which can be used in detergent materials, detergent compositions, detergent compounding agents, etc., and can solve problems such as loss of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

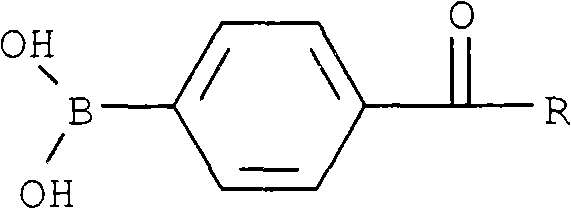

Method used

Image

Examples

preparation example Construction

[0102] Preparation of laundry bars

[0103] The laundry bars of the present invention can be processed in conventional laundry bar manufacturing equipment such as, but not limited to: mixers, plodders (e.g. two-stage vacuum molding machines), extruders, Cutting machines, logo-stampers, cooling tunnels and packaging machines.

[0104] Prepare the premix before adding it to the soap.

[0105] According to the present invention, the method is a method of incorporating an enzyme into a laundry soap bar and also maintaining enzyme activity.

[0106] The method of the present invention is used to prepare laundry soap bar, and it comprises the following steps:

[0107] a) Premixes are prepared by mixing enzymes, stabilizers and polyols as liquid formulations;

[0108] b) mixing the premix of step a) with soap;

[0109] c) refining the mixture of b) into refined soap; and

[0110] d) Compressing the refined soap of step c).

[0111] The premixes of the present invention can be a...

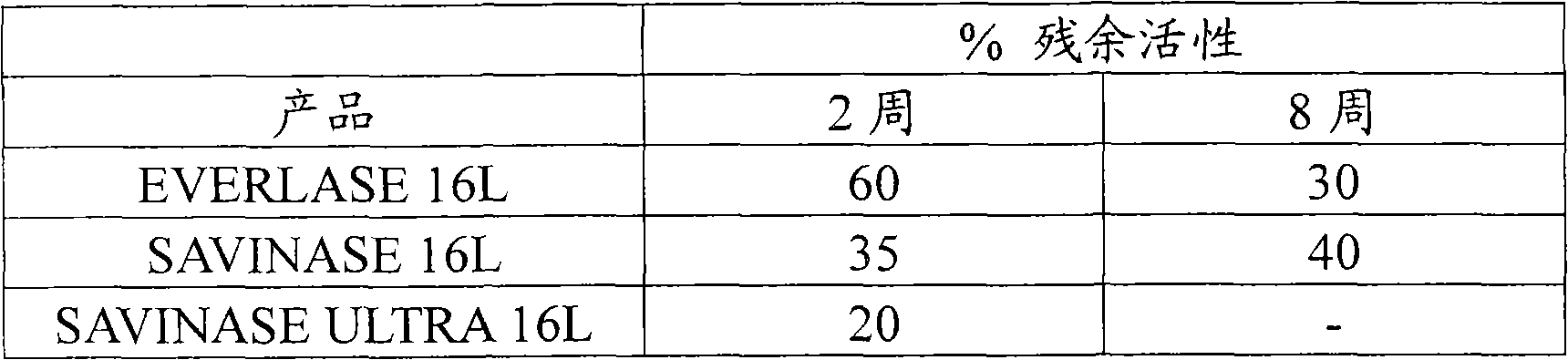

Embodiment 1

[0123] This example shows a general method for making an enzyme-containing soap bar, where the various ingredients are added to the soap separately.

[0124] Each stabilizing ingredient was added to the soap separately.

[0125] Three different proteases were tested:

[0126] 0.2% EVERLASE 16L by weight of the final laundry bar;

[0127] 0.2% SAVINASE 16L by weight of the final laundry bar;

[0128] 0.2% SAVINASE ULTRA 16L by weight of the final laundry bar.

[0129] These proteases were added to the soap at room temperature (RT) and mixed. Separately, 2% glycerin and 0.2% citric acid were added to the soap and mixed.

[0130] 2% sodium borate was added to the mixture containing Everlase 16L and Savinase 16L.

[0131] This mixture is transferred to a refiner, then to a molding press, where it is finally embossed.

[0132] Stability results are shown as percent residual enzyme activity after storage at 35°C for 2, 4, 6 or 8 weeks.

[0133]

[0134] If no loss of activ...

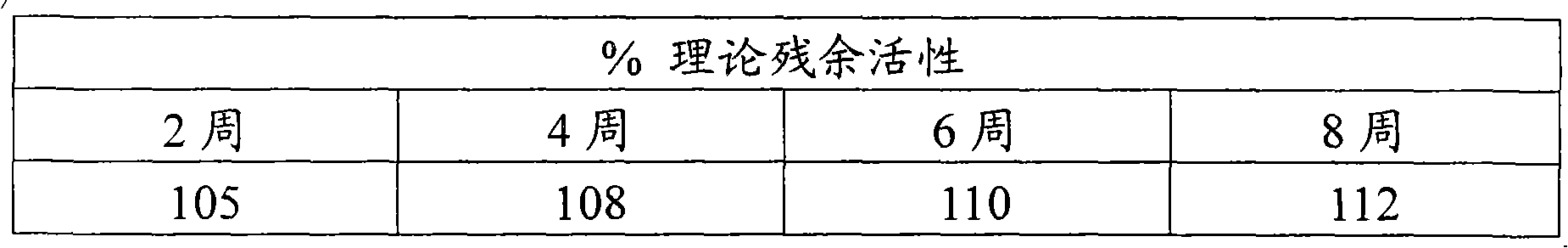

Embodiment 2

[0138] In this example, the stabilizer was added to the premix, which was then mixed with the soap without refining.

[0139] The components of the premix are:

[0140] EVERLASE 16L 0.2%,

[0141] Glycerin 2%,

[0142] Borax 2%,

[0143] Citric acid 0.2%.

[0144] The ingredients of the premix are blended in a mixer to make a slurry, which is then added directly to the soap. This mixture is sent directly to a molding press, whereupon the product is embossed.

[0145]

[0146] These results show that the storage stability is surprisingly high.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap