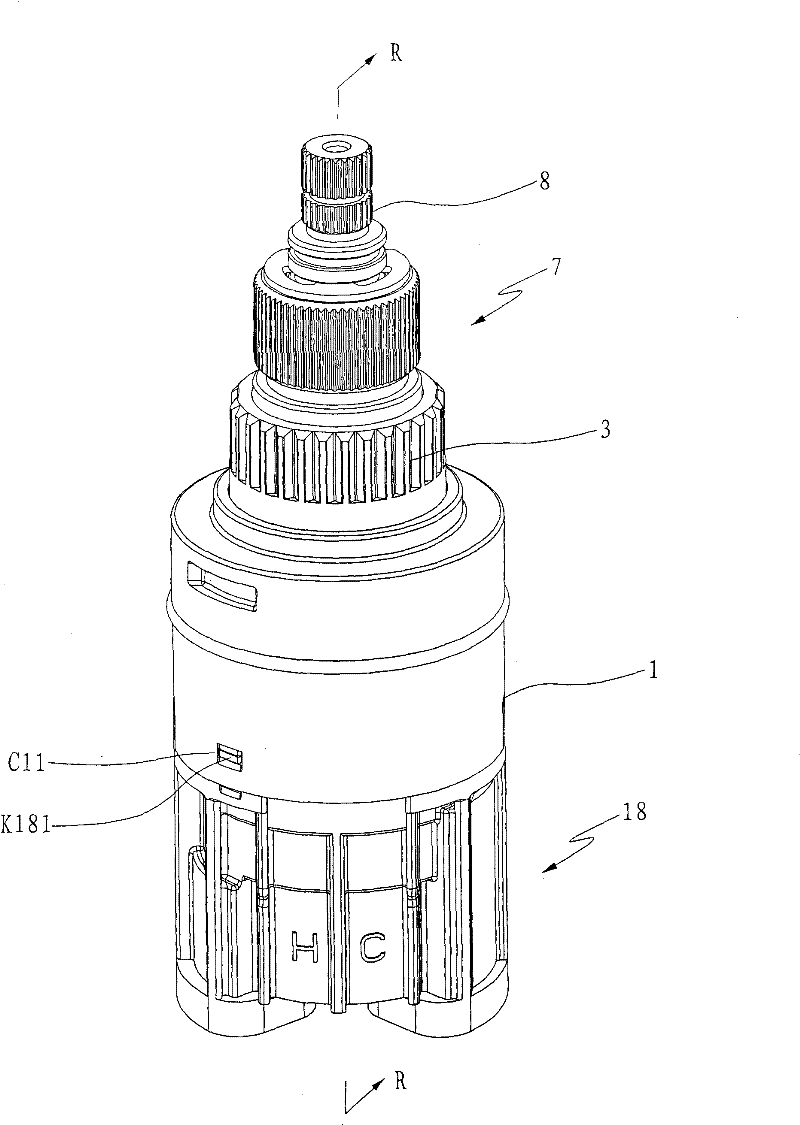

Constant temperature mixed valve core

A mixing valve, constant temperature technology, applied in the direction of sliding valve, valve detail, multi-way valve, etc., to achieve the effect of internal pressure balance, stable and reliable outlet water temperature, accurate and reliable temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

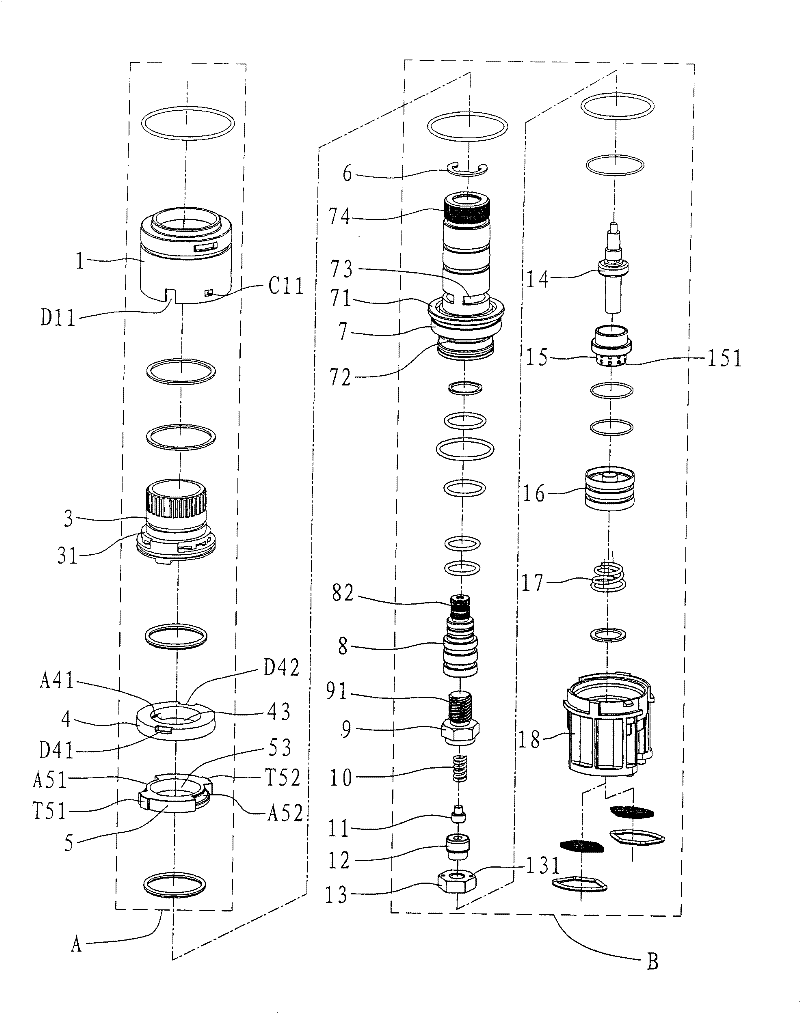

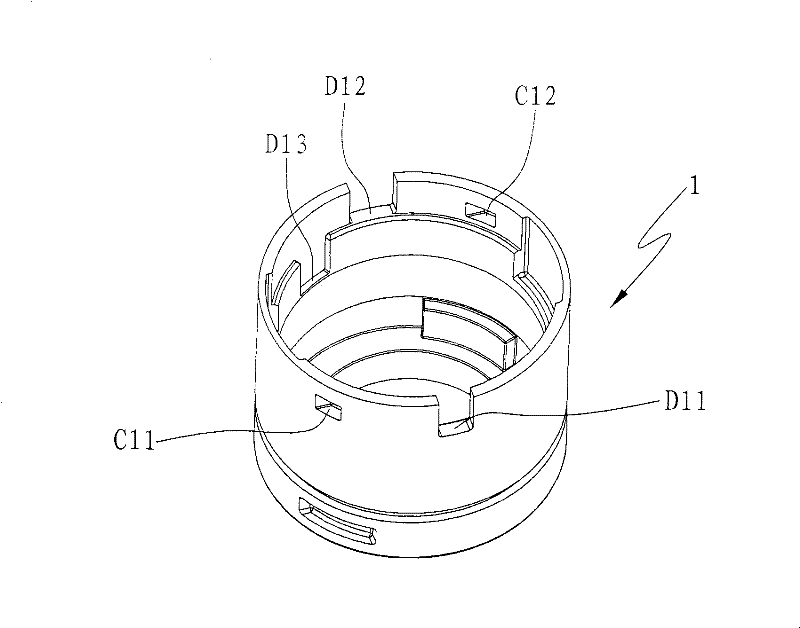

[0049] like Figure 3a-1 , Figure 3a-2 and cooperate Figure 3bAs shown, two positioning blocks D31 and D32 are arranged upward near the outer edge of the lower part of the ceramic sheet upper seat 3, while the other two positioning bumps T31 and T32 are formed on the lower end face downward; The two positioning blocks D31, D32 of the chip seat 3 are fitted between the two positioning blocks E11, E12 of the housing 1 respectively, so that the rotation angle of the ceramic chip seat 3 relative to the housing 1 is limited between 0→90°.

[0050] like Figure 3c-1 and Figure 3c-2 As shown, the middle part of the upper ceramic sheet 4 is provided with a central sleeve hole 43 of a set temperature adjustment mechanism, and one side of the upper ceramic sheet 4 is provided with two water outlet slots A41, A42 and an inner edge 44 combined therewith; One side is provided with the groove D41, D42 that cooperates mutually with two positioning lugs T31, T32 of ceramic sheet upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com