High-performance magnetostrictive transducer of using multi-layer winding coil

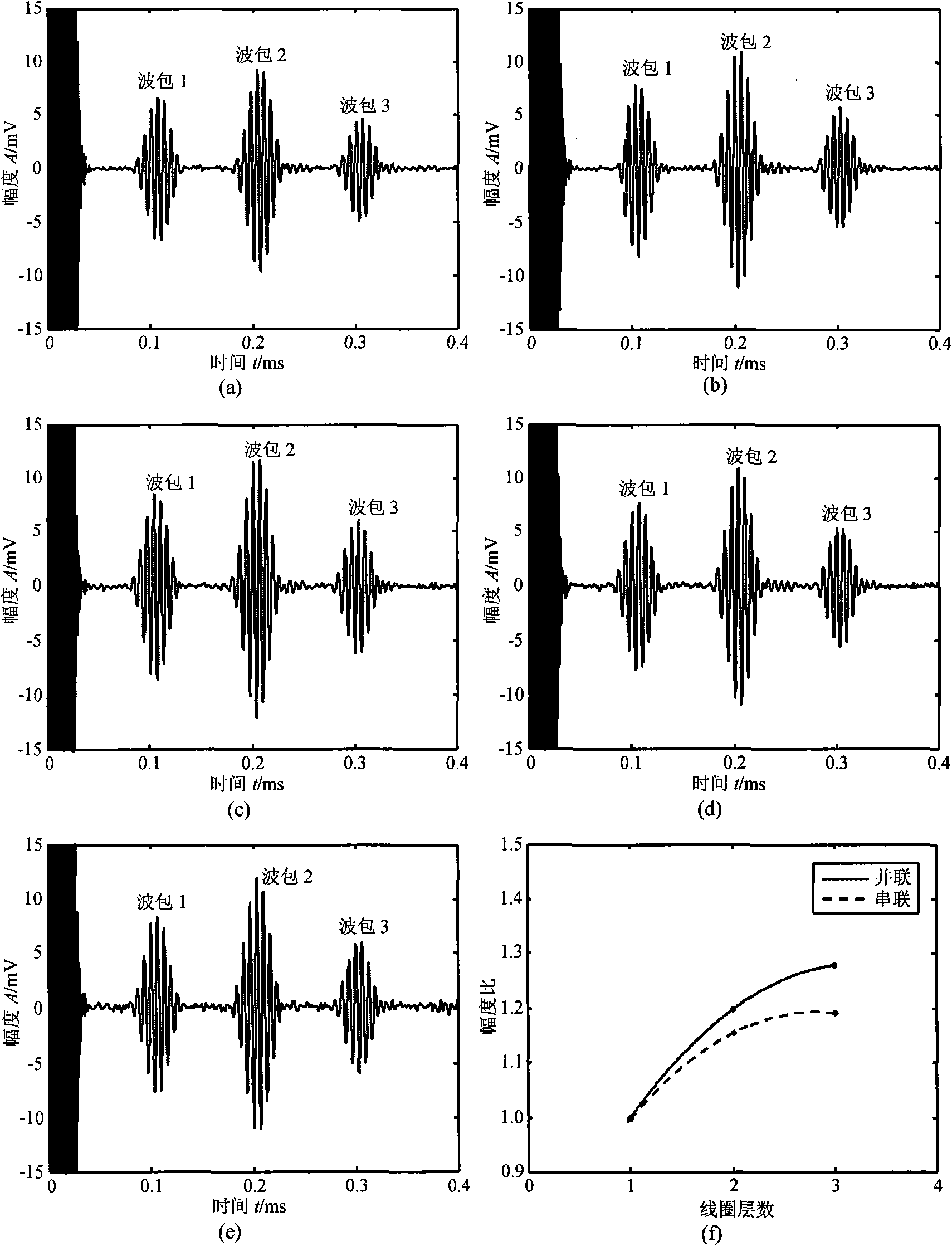

A magnetostrictive and wound coil technology, which is applied in the direction of using electric/magnetic devices to transmit sensing components and instruments, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem that the size cannot be measured quickly and accurately in service, Achieve the effect of increasing the amplitude and improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Provide following embodiment in conjunction with the content of the inventive method:

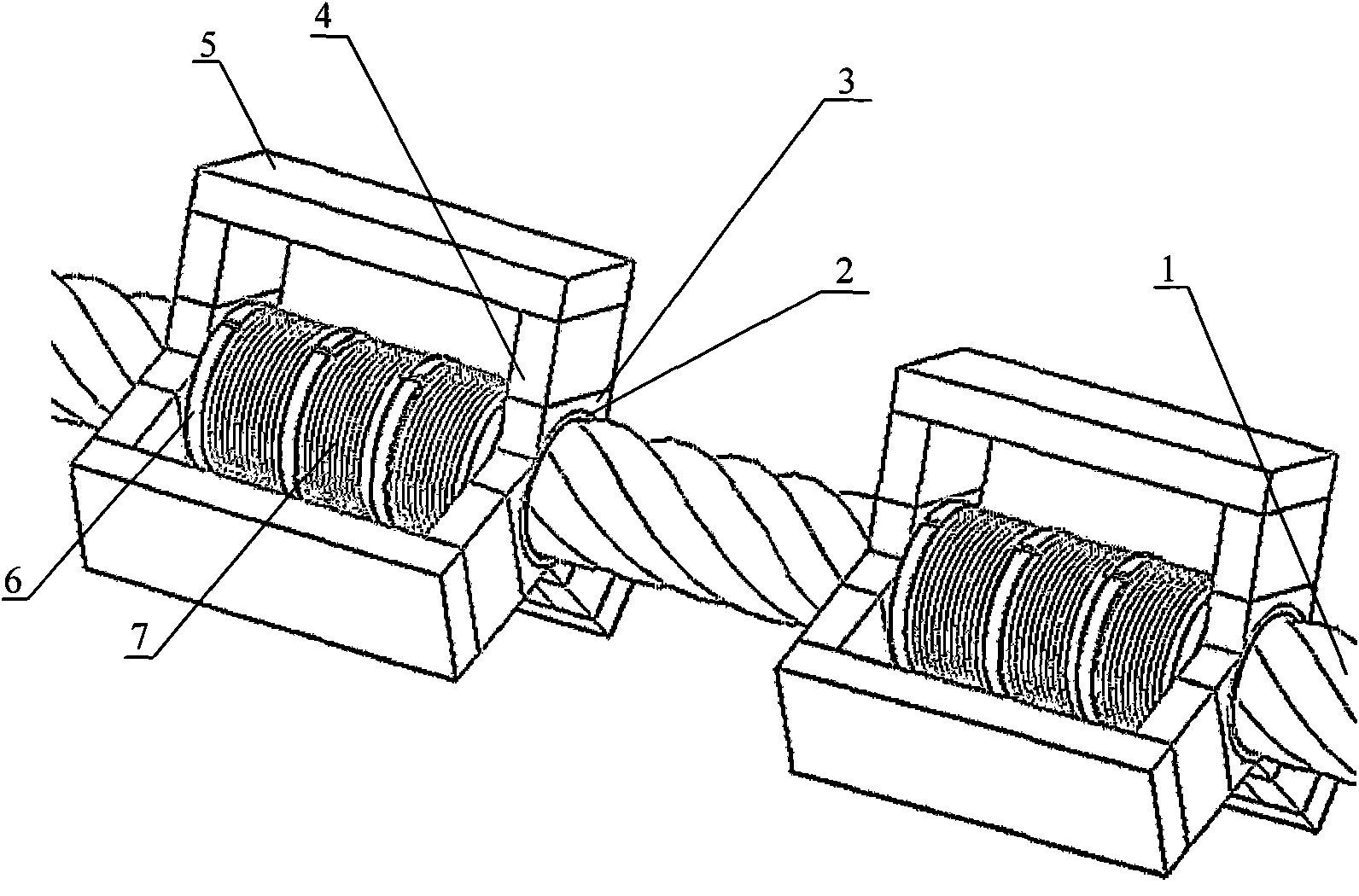

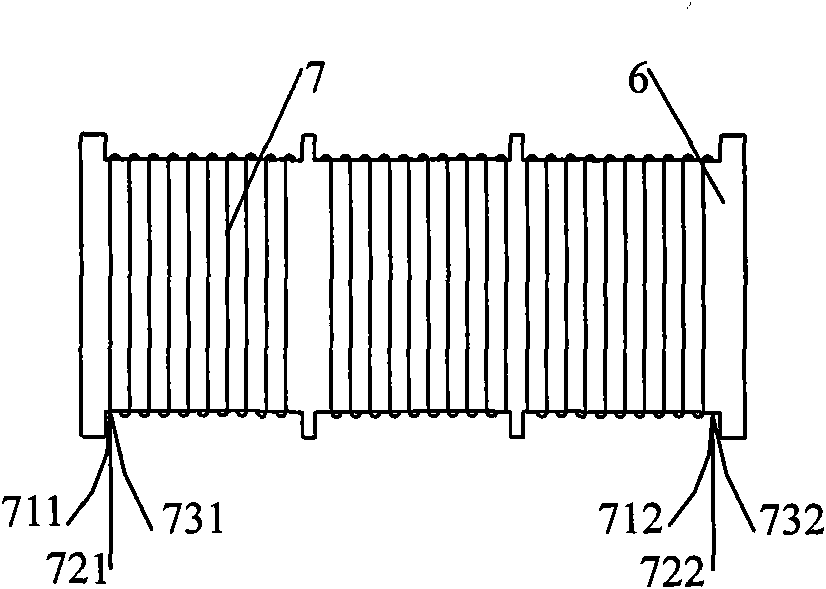

[0013] The structure of this embodiment is as figure 1 As shown, it mainly includes the sensor at the excitation end and the sensor at the receiving end. The sensor mainly includes a saddle 3, a permanent magnet 4, a yoke 5, and a clip 2 and a solenoid 6 sleeved on the outer surface of the steel strand 1. Both ends and the middle part of the outer surface of the tube 6 are provided with steps, and the part between every two steps is surrounded by an enameled wire 7, and the winding direction is changed every time the enameled wire 7 passes through a step, and the two ends of the enameled wire 7 are connected with the signal generator connected. Both ends of the solenoid 6 are provided with a clip 2, and the outer surface of the clip 2 is covered with a saddle 3, and the outer surface of the saddle 3 is evenly fixed with three permanent magnets 4 along the circumferential direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com