Electric component

An electrical component, current technology, applied in electrical components, transformer/inductor components, circuits, etc., can solve problems such as damage, degraded magnetic performance, overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

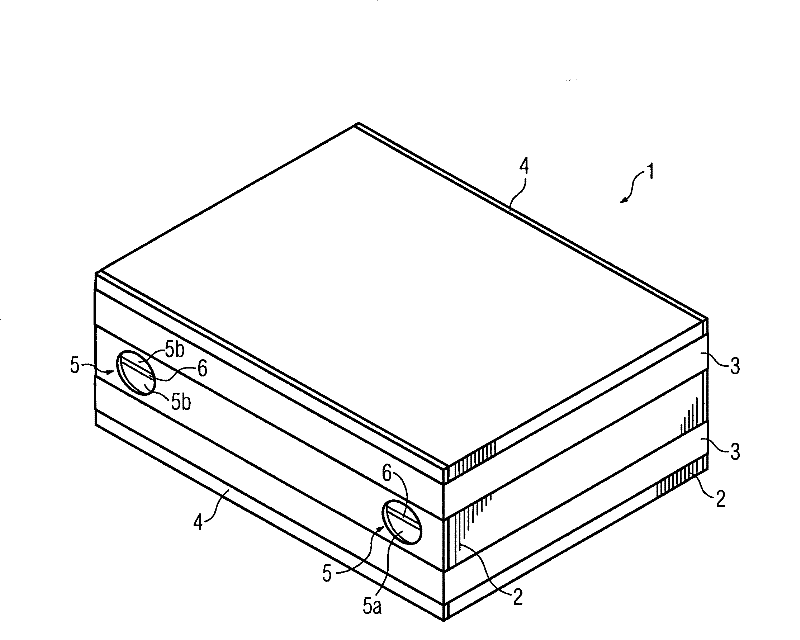

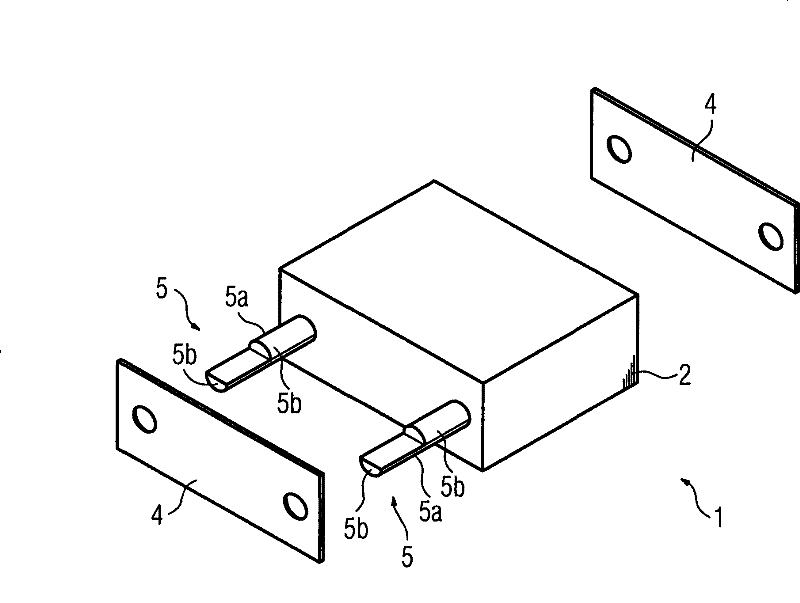

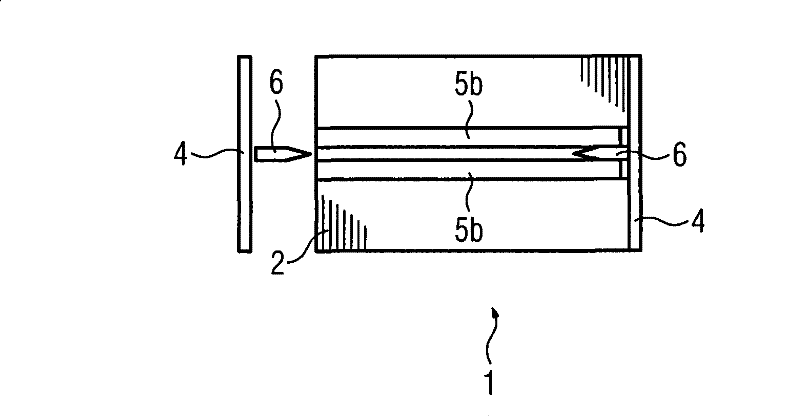

[0017] figure 1 A plate stack 1 of an electrical component is shown, which can be a transformer or an inductor. The electrical component includes a ferromagnetic core fitted with at least one coil such that a magnetic flux (not shown) is generated in the core when current flows through the coil.

[0018] The core consists of at least one laminated core 1 which consists of ferromagnetic plates 2 which rest against each other with their planar sides. board 2 in figure 1 Indicated by thin dashes. as by figure 1 It can be seen that the relatively thin plate has a rectangular shape. The panels 2 are joined together by two straps 3 which rest on the outside and surround the stack 1 of panels. The tie hoop 3 can be an adhesive tape. A non-ferromagnetic plate 4 , such as an aluminum cover plate, is located on the two outer sides of the laminated core 1 . The plates 3 and 4 have two circular through-holes extending transversely through the plates, into which are inserted cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com