An electric vehicle inverse charging converter

A reverse charging and converter technology, applied in the field of electric vehicle reverse charging devices, can solve the problems of shortening the service life of the battery, frequent charging of the battery, excessive consumption of the battery, etc., and achieve the effects of prolonging life, preventing aging, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

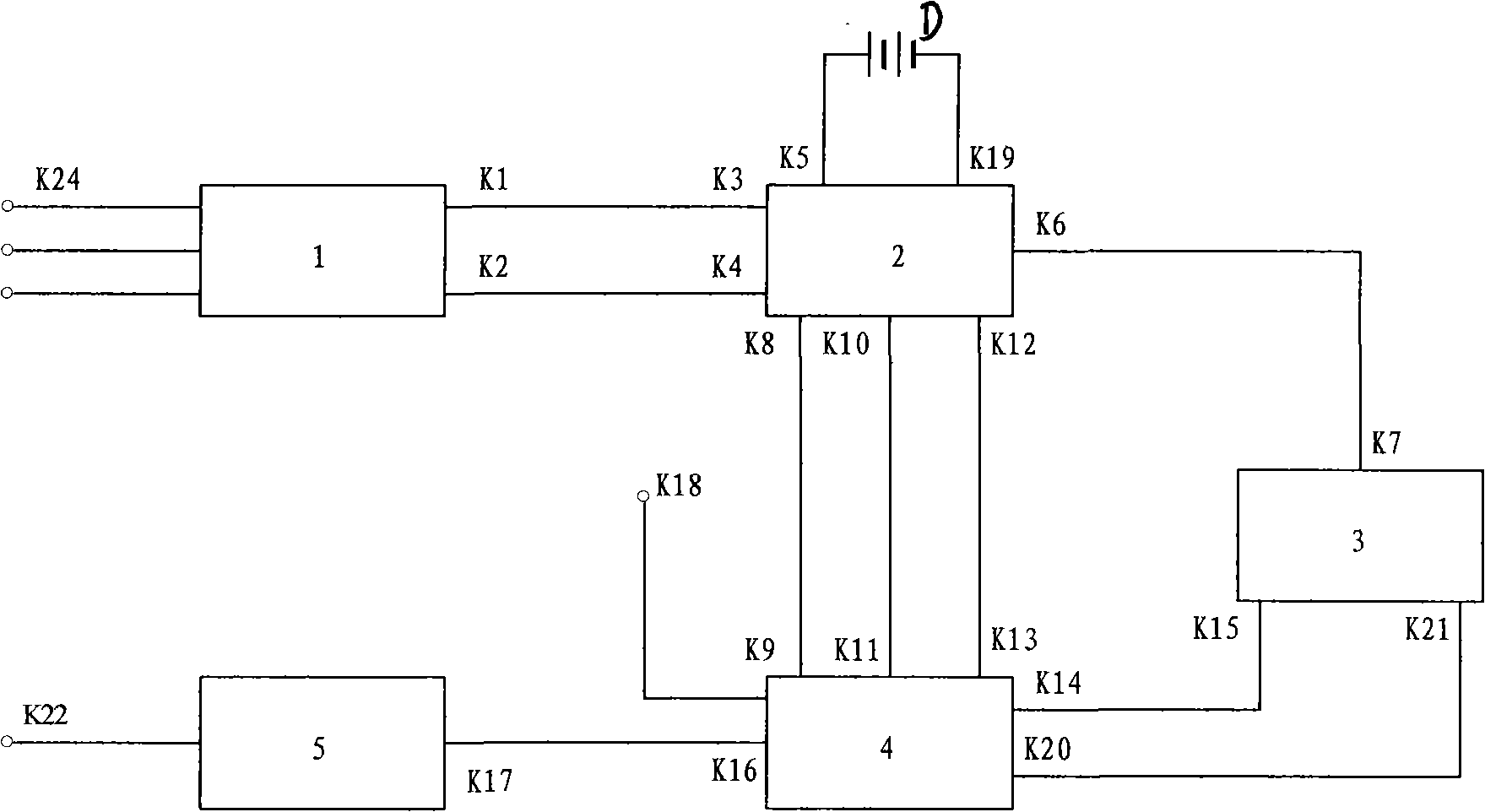

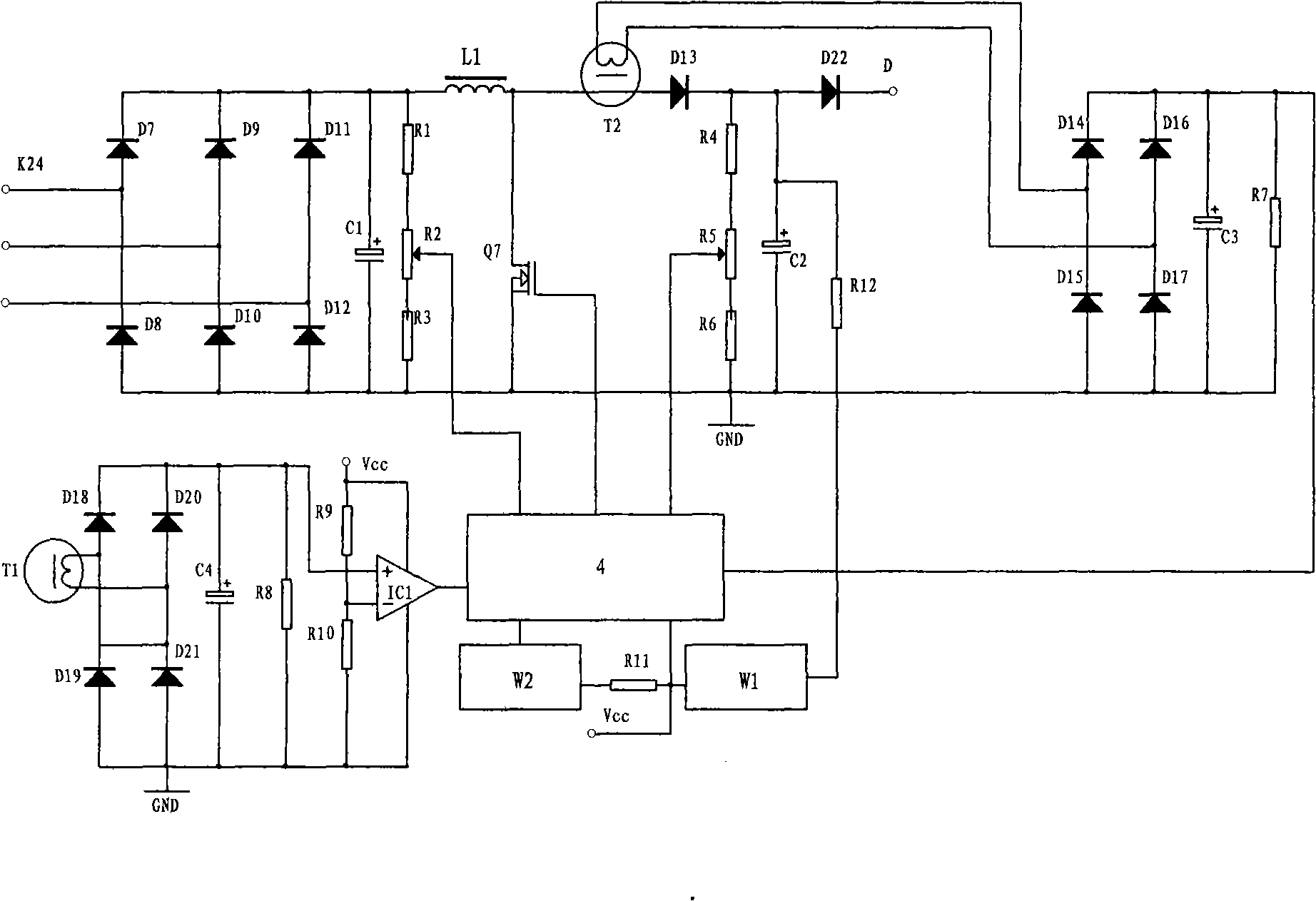

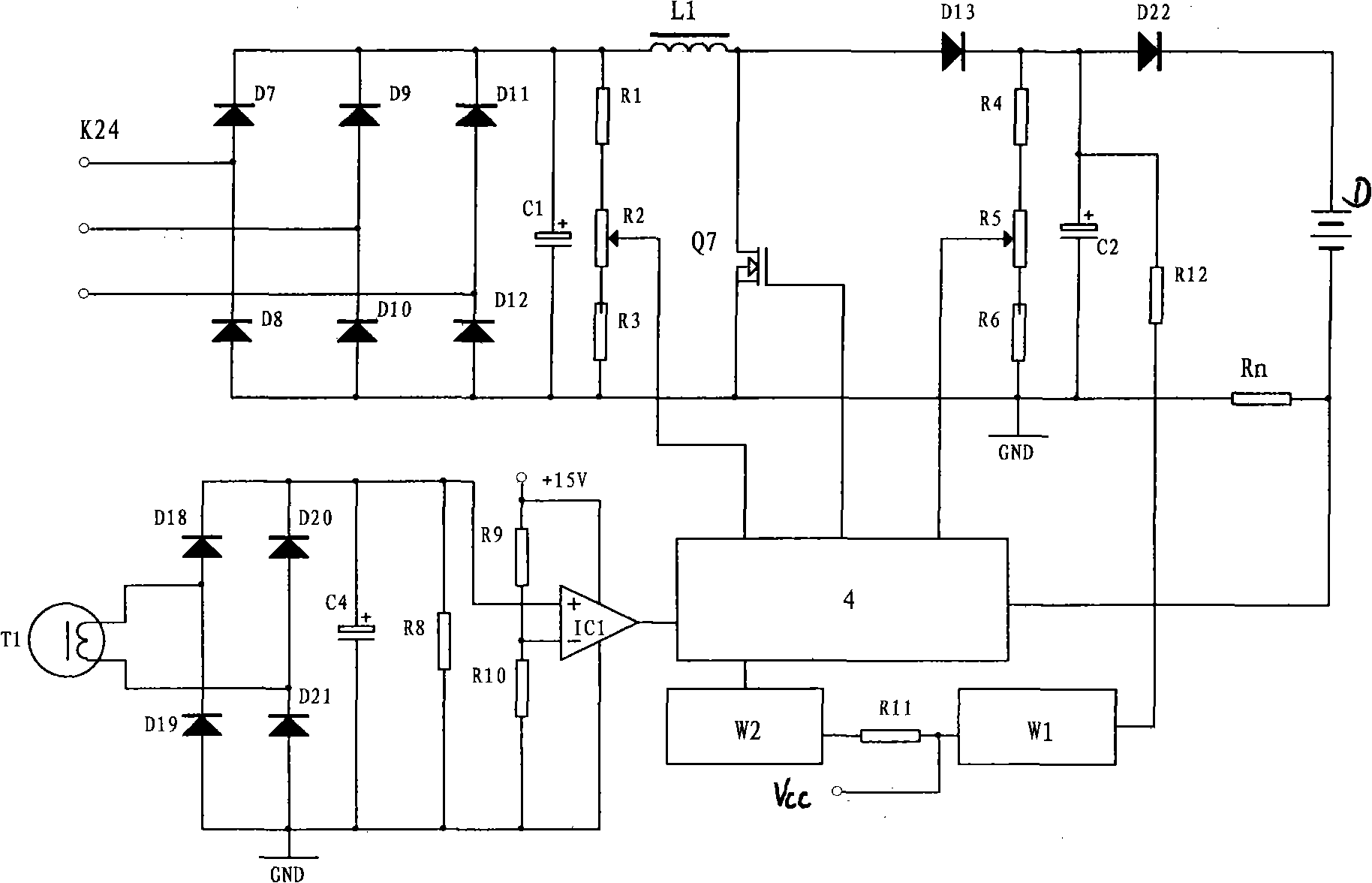

[0024] Such as figure 1 As shown, the present invention includes a back EMF pre-collection module 1, a constant current boost module 2, a self-power supply module 3, a switching power supply integrated controller 4 and a discrimination module 5, the input terminal K24 of the back EMF pre-collection module 1 and the motor The three phase lines A, B, and C are connected, and the high and low potential output terminals K1 and K2 of the back EMF pre-collection module 1 are respectively connected to the high and low potential input terminals K3 and K4 of the constant current boost module 2, and the constant current boost The positive charging terminal K5 of the module 2 is connected to the positive pole of the battery D, the negative charging terminal K19 of the constant current boost module 2 is connected to the negative pole of the battery D, the power supply t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com