Double-layer or multi-layer scalable foot-miss prevention plate Mechanism for removing clearance between rail transit carriage and platform

A technology of anti-treading and carriage, which is applied in the direction of stations, tracks, railway car body parts, etc., can solve the problems of being unable to adapt to trains of different specifications, high wear and failure rates, and complicated structures, and achieves simple structure and low cost. Inexpensive and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

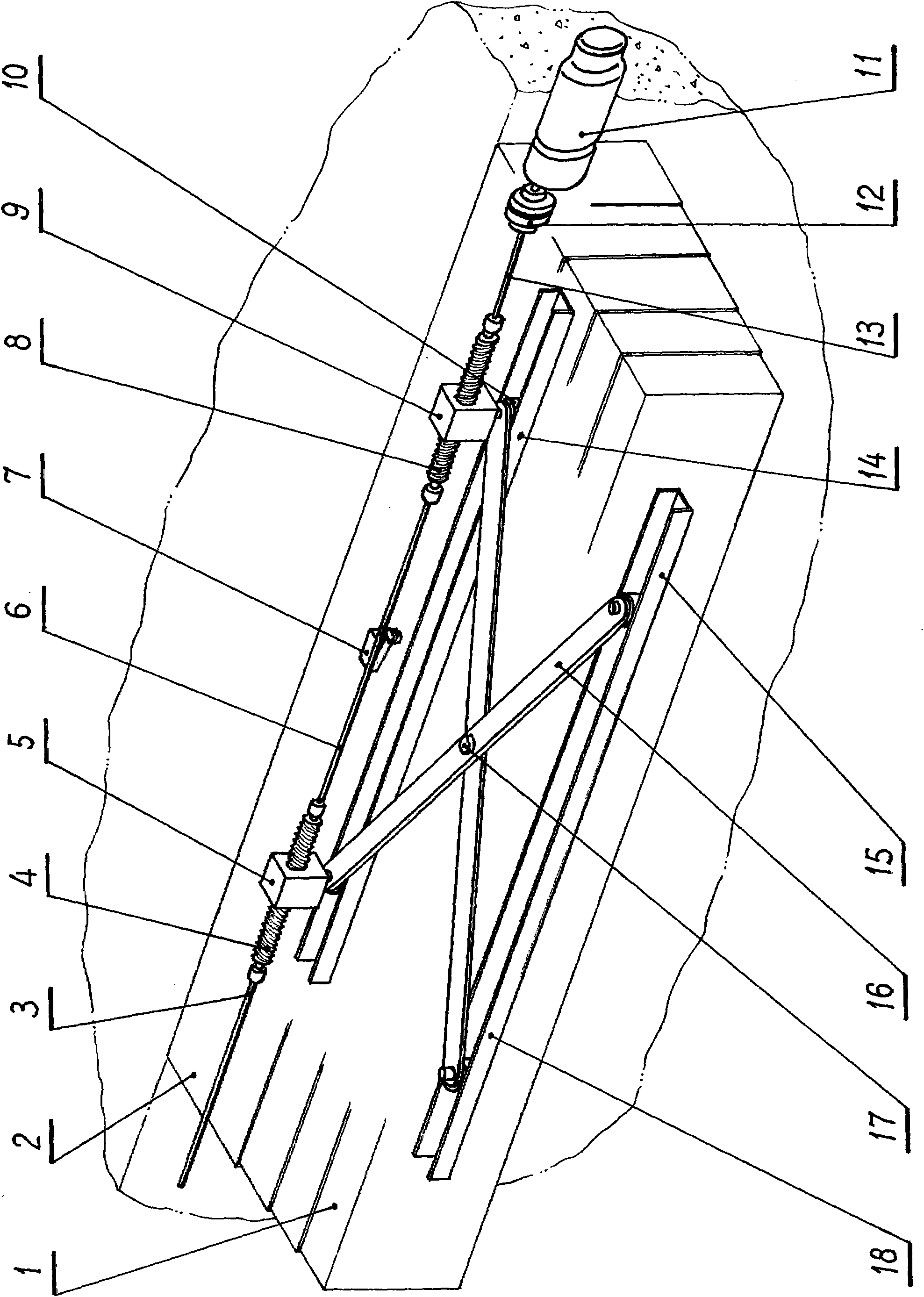

[0011] The embodiment in the figure is a gap eliminating mechanism composed of five layers of anti-stepping boards. The width of the mechanism is 50 mm when the anti-tread plate is fully retracted and 184 mm when fully extended. Assuming that the compartment door opening is 1300 millimeters, add 200 millimeters of parking accuracy error at both ends, and divide it into two because the mechanism is too narrow and too long, and the length of the mechanism is 850 millimeters. The height of the mechanism is 90 mm.

[0012] The power of the mechanism comes from a 550 geared motor (11) using a safe voltage. The 550 deceleration motor (11) is fixedly connected to the right-handed screw (8) through the frictional safety coupling (12) through the transmission flexible shaft C (13), and then through the transmission flexible shaft B (6) to the left-handed screw (4) It is fixedly connected, and power can also be transmitted to the next gap elimination mechanism through the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com