Composite static start-stop method mass flowmeter calibration system

A mass flowmeter and calibration system technology, applied in the field of compound static start-stop method mass flowmeter calibration system, can solve the problems of reduced accuracy, system paralysis, calibration system accuracy error, etc., so as to improve the accuracy and stability, improve the system Reliability, the effect of avoiding precision errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

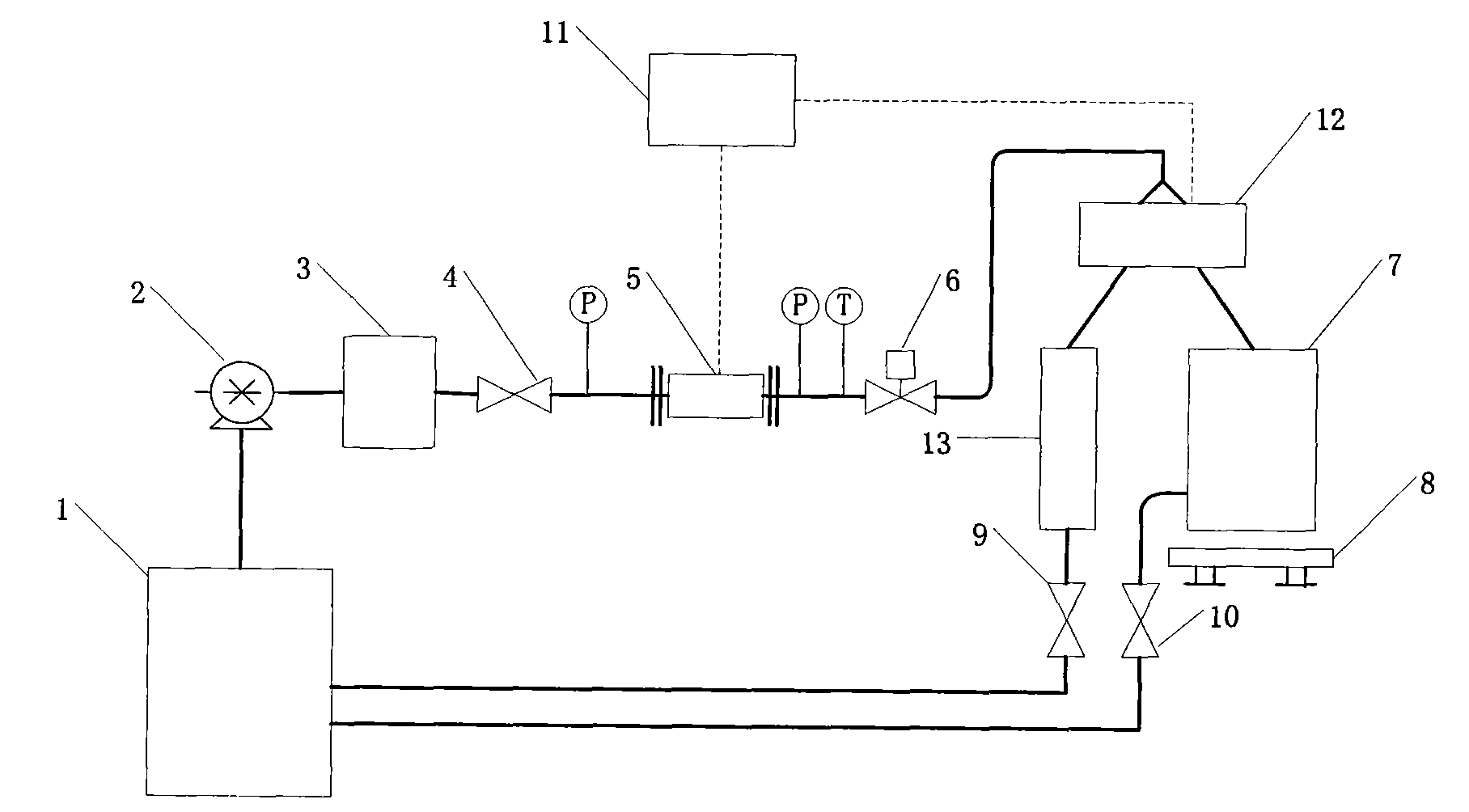

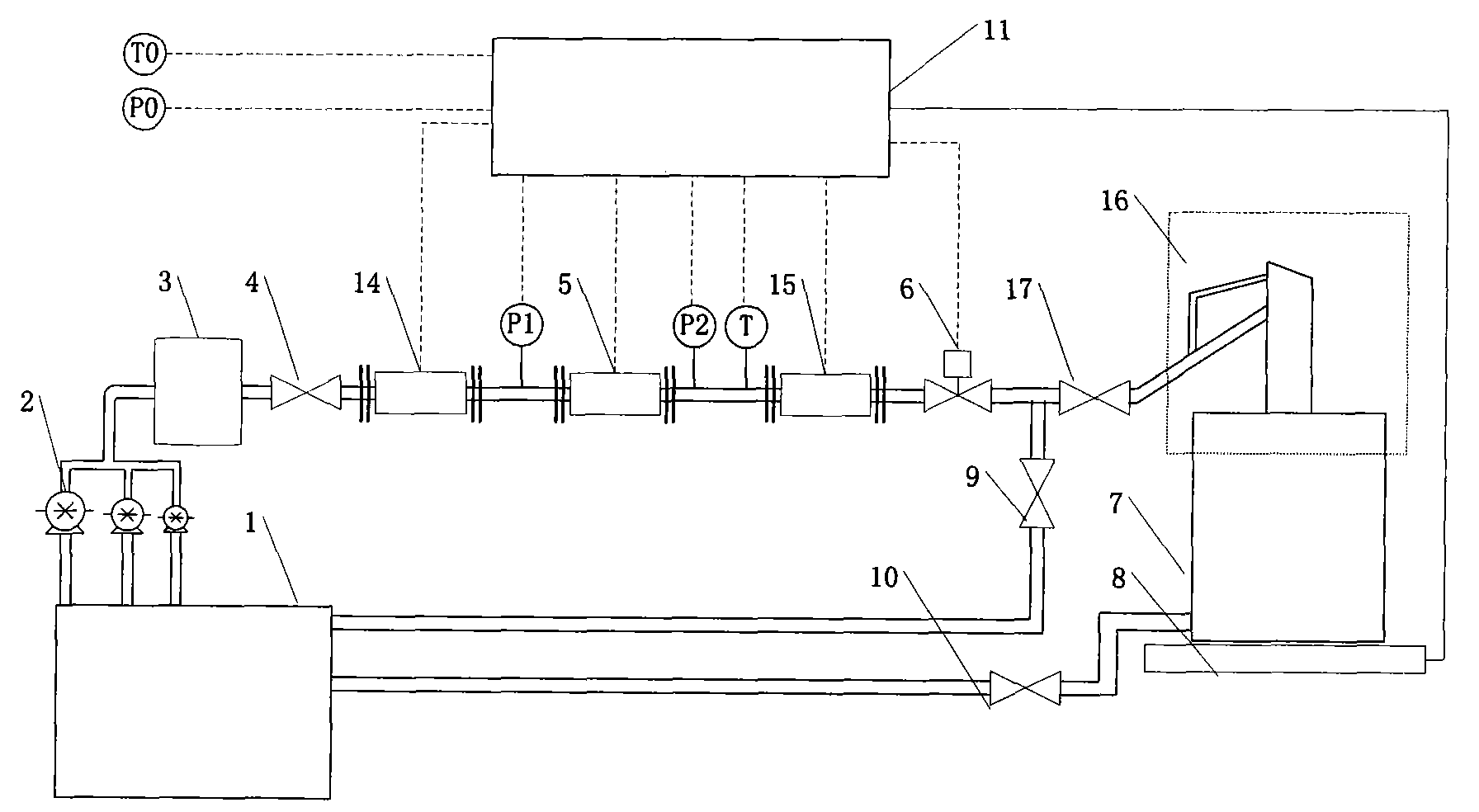

Embodiment 1

[0049] When the shut-off valve 9 is opened and the shut-off valve 10 is closed, the system works in a static start-stop method. For flow pump group 2, select the flow pump that corresponds to the flow point to be calibrated. For standard mass flowmeter groups 14, 15 select the standard mass flowmeter consistent with the range of the mass flowmeter 5 to be tested. When working, the fluid in tank 1 is flowed The pump is pumped out, and the fluid is smoothly injected into the weighing container 7 through the first set of standard mass flow meters 14, the mass flow meters to be tested 5, the second set of standard mass flow meters 16 and the steady flow device 16. When a measurement period is completed, the shut-off valve 9 shuts off the liquid flow, and the electronic scale 8 can weigh the mass of the liquid flowing into the weighing container 7 and transmit the data to the computer 11. Compare and analyze the data measured by the first group of standard mass flow meters 14, the mass...

Embodiment 2

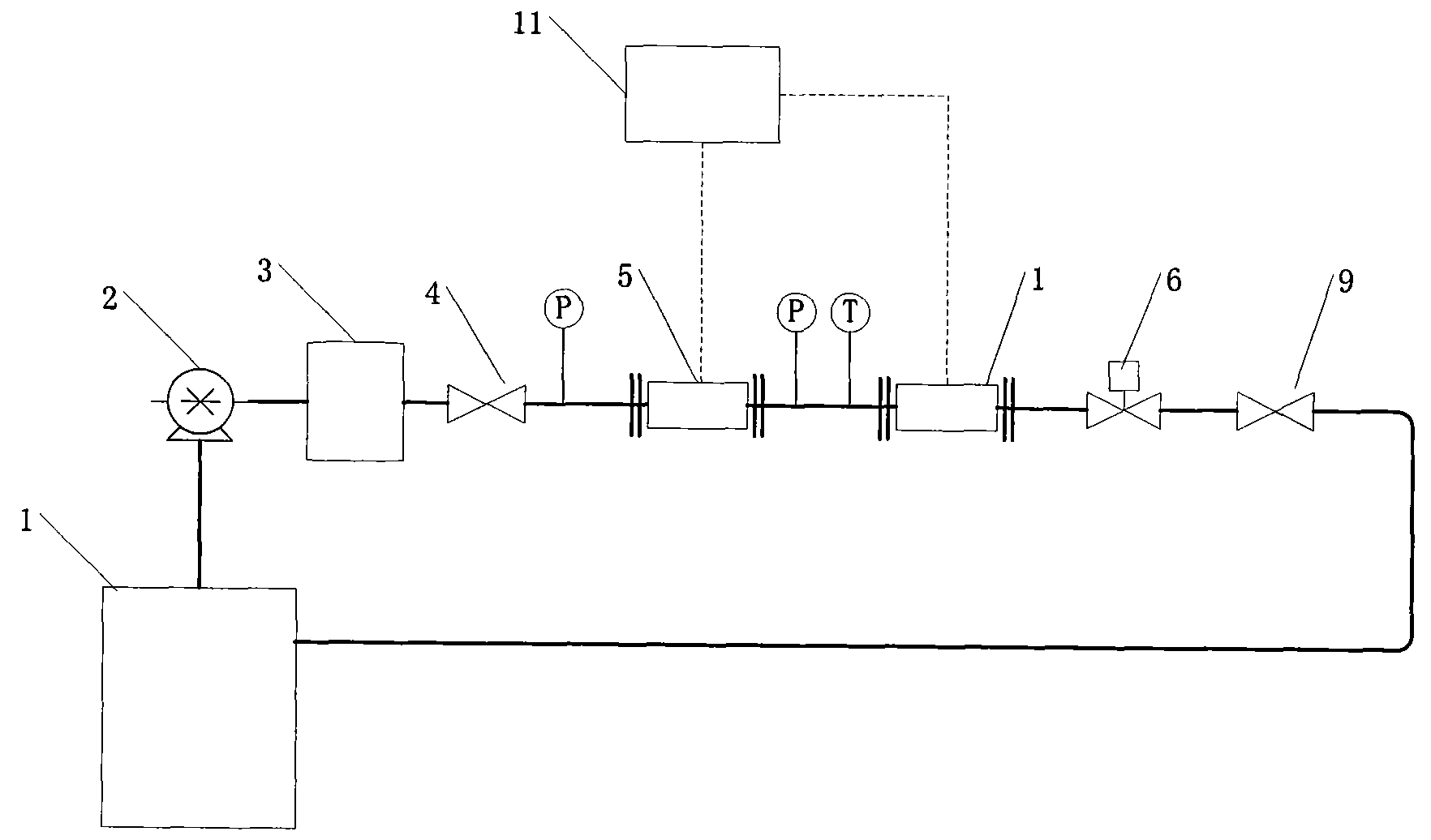

[0051] When the shut-off valve 9 is closed and the shut-off valve 10 is opened, the system works in a double-standard meter calibration mode. When working, a standard mass flow meter that matches the measuring range of the mass flow meter 5 to be measured can be manually selected. The fluid in the water tank 1 is pumped out by a flow pump, and the fluid passes through the first group of standard mass flow meters 14, the mass flow meters to be tested 5, and the second group of standard mass flow meters 15, and then directly flows back to the water tank 1. When a measurement cycle is completed, each data is transmitted to the computer 11 for data analysis. If the data error between the first group of standard tables and the second group of standard tables is less than the empirical error, the data in this group is credible and effectively retained; if the data error is greater than the empirical error, the data in this group will be eliminated, and the credible data and the test The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com