High-voltage circuit-breaker connector and high-voltage circuit breaker using same

A technology for high-voltage circuit breakers and connectors, which is applied in the direction of circuit breakers with excessive current, overload protection circuit breakers, circuits, etc. Large mechanical vibration and other problems, to achieve the effect of stability, improve work reliability and life, reduce noise and mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

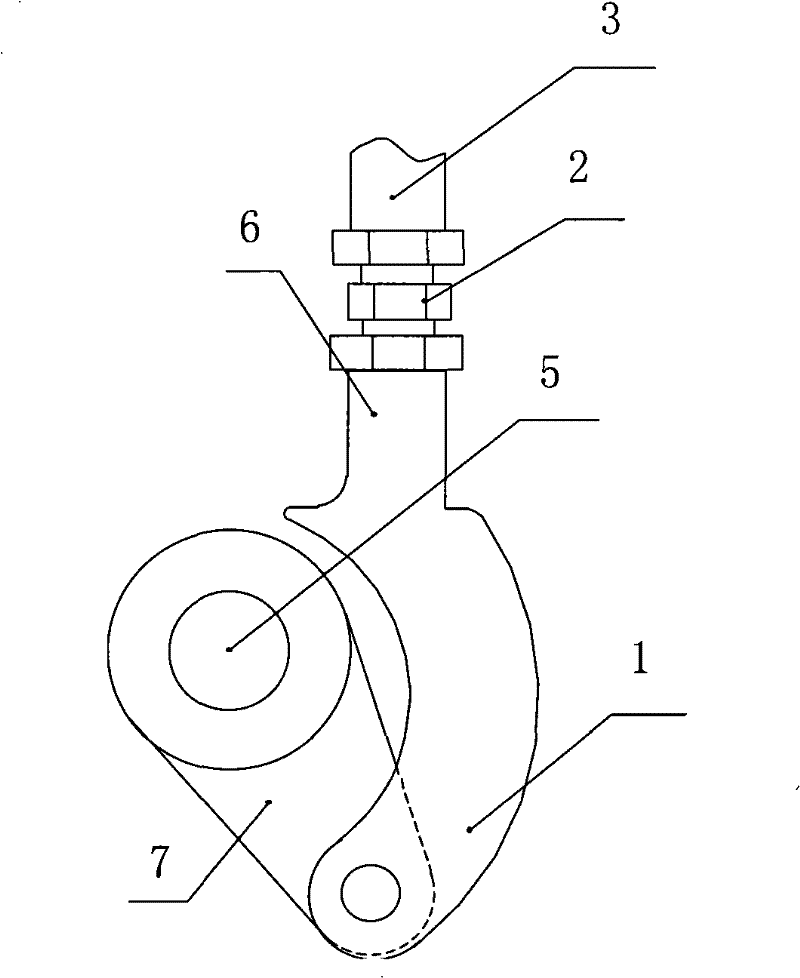

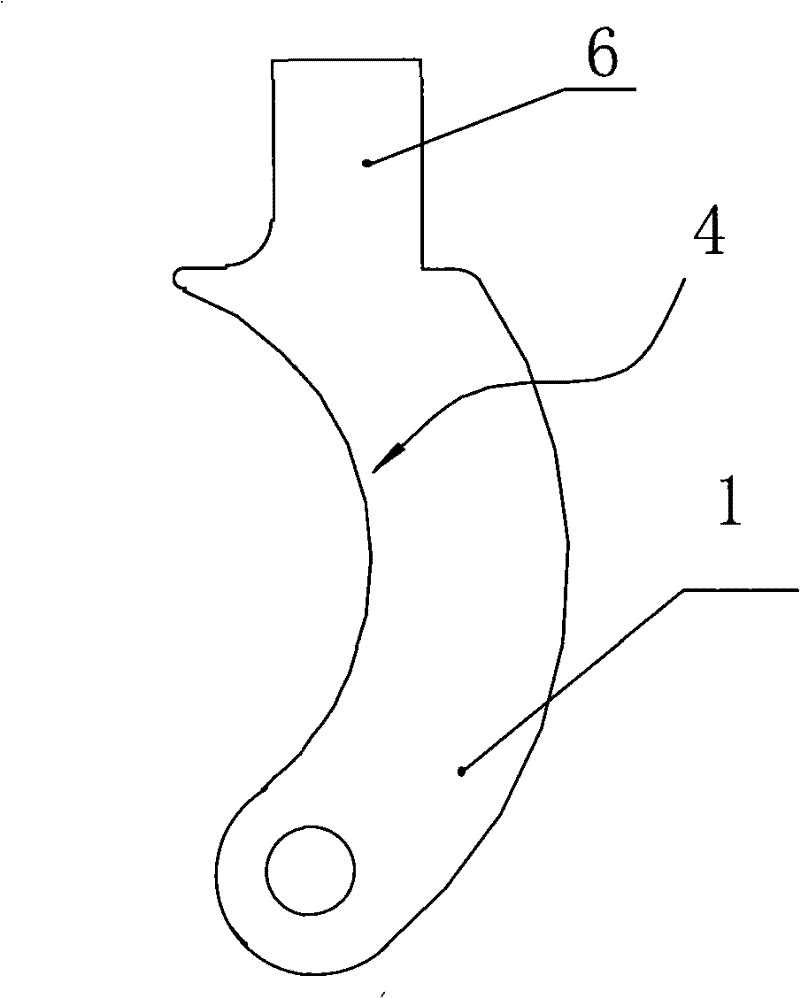

[0024] Embodiment one: if figure 1 , figure 2 As shown, the connecting head 1 connecting the transmission rod 3 of the high-voltage circuit breaker to the inner crank arm 7 is made of bent aluminum alloy bar, and it is a curved bar structure in a concave arc shape toward the crank arm shaft 5 as a whole. In this embodiment, the connecting head 1 has a C-shaped circular arc structure as a whole. One end of the arc-shaped connector 1 is provided with a connecting portion 6 connected to the driving rod, and is connected to the driving rod 3 through the adjusting screw 2 connected to the connecting portion 6 , and the other end of the connecting head is hinged with the inner crank arm 7 . The shape and size of the arc-shaped connector 1 are determined according to the length of the crank arm shaft 5 and the inner crank arm 7 of the circuit breaker and the operating torque during the opening and closing process of the circuit breaker, so as to ensure that the length of the inner ...

Embodiment 2

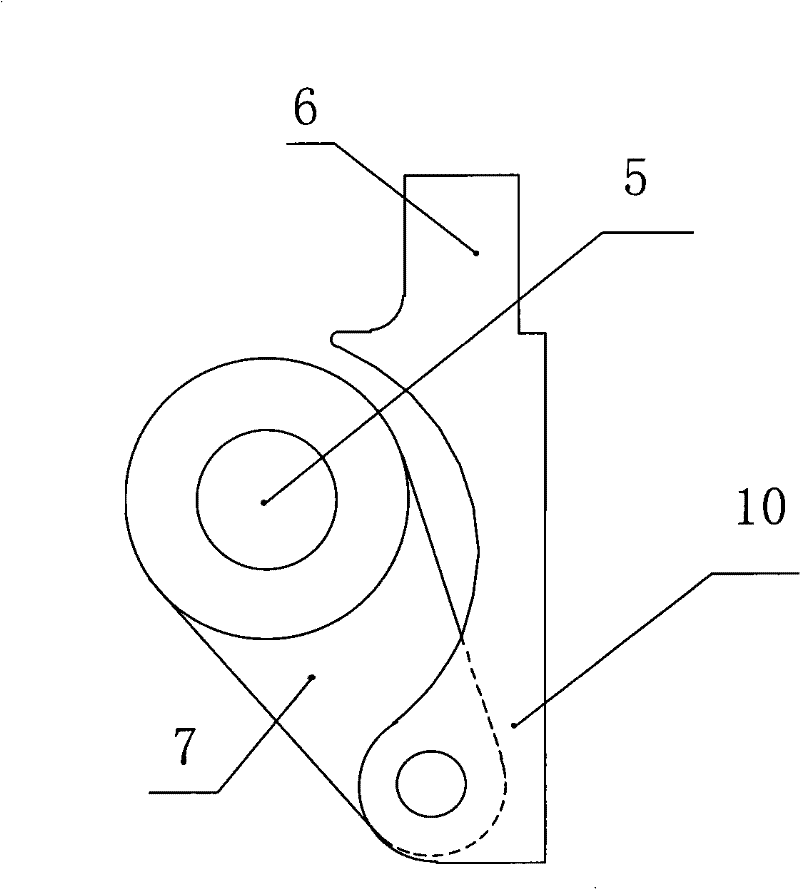

[0027] Embodiment two: if image 3 As shown, the difference between the second embodiment and the first embodiment is that the connecting head 10 is only provided with a C-shaped concave arc structure on the side facing the crank arm shaft 5, and it has a "〗" shape structure as a whole.

Embodiment 3

[0028] Embodiment three: as Figure 4 As shown, the difference between the third embodiment and the first embodiment is that the connecting head 20 has a groove-shaped structure as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com