Towed rotary vertical section-to-section assembling construction system for large-sized spoke type ferris wheel disc

A Ferris wheel and spoke-type technology, which is applied in the field of installation and construction systems for large-scale spoke-type Ferris wheel discs, can solve the problems of inability to use large cranes, difficulty, etc., and achieve the effects of superior advancement, convenient operation, and cost-saving measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

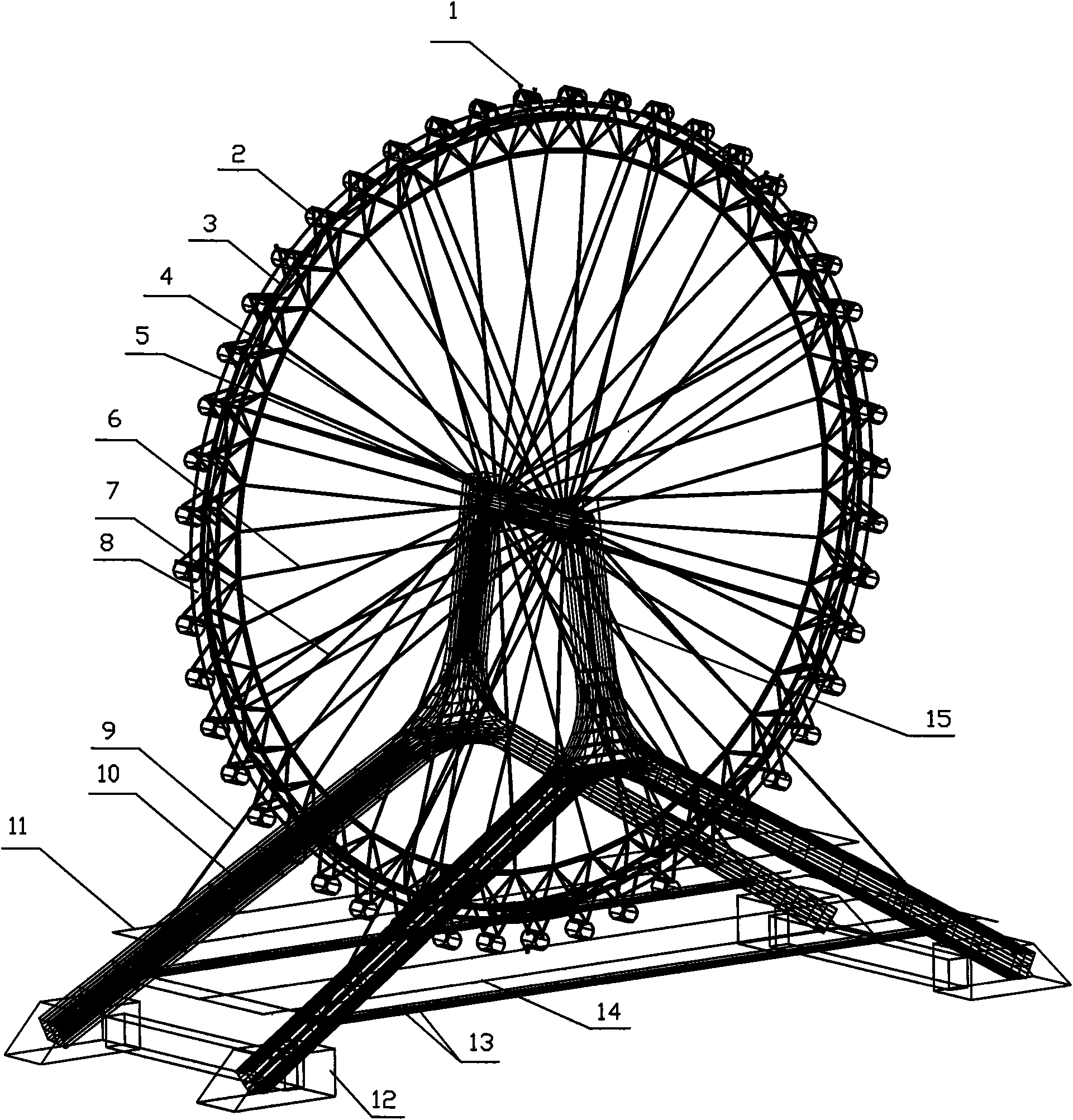

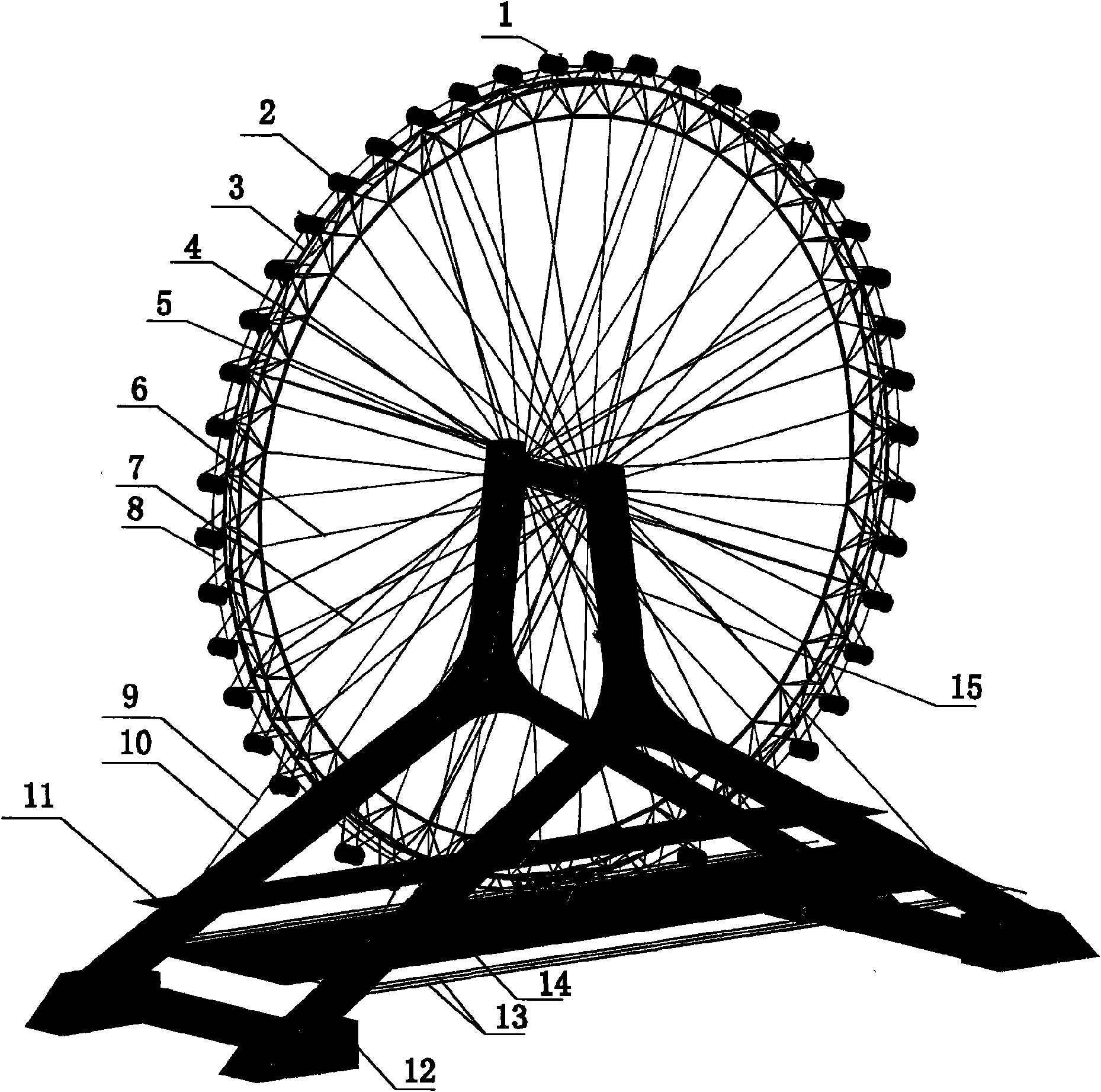

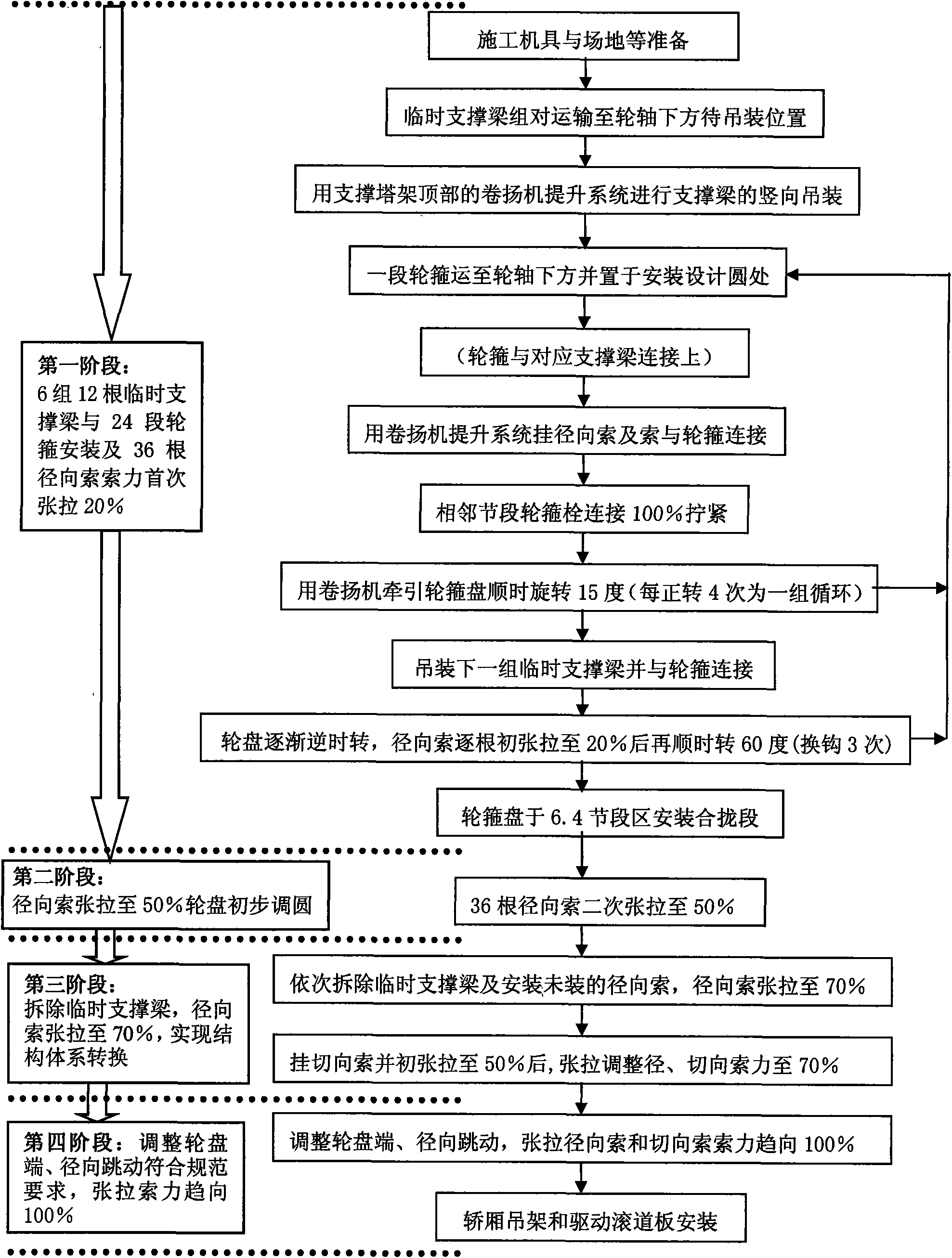

[0040] Taking the Ferris wheel installation of 110m in Tianjin Yongle Bridge as an example below, the installation and construction method of the present invention will be further described in detail.

[0041] The supporting frame of the ferris wheel in this embodiment is a herringbone door-type steel box frame. The height of the tower top from the standing water surface is 67m, and it rides on the banks on the upper and lower sides of the bridge. Connecting to the top of the herringbone tower is a main shaft with a diameter of 2.8m and a span of 21m. The wheel of the Ferris wheel is a turntable formed by tensioned radial steel cables and steel pipe truss tires, and is a flexible structure that rotates slowly around the horizontal main axis supported by herringbone steel towers on both sides. There is a raceway disc driven by the friction wheel on the outer ring. On the outer ring of the roulette, 48 sedan chairs that can carry 8 people are hung at equal distances.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com