Jet conductive ink

A technology of conductive ink and conductive particles, which is applied in ink, household utensils, applications, etc., can solve the problems of high solid content of metal nanoparticles and no printing effect data, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 prepares nano-silver emulsion ink-jet conductive ink

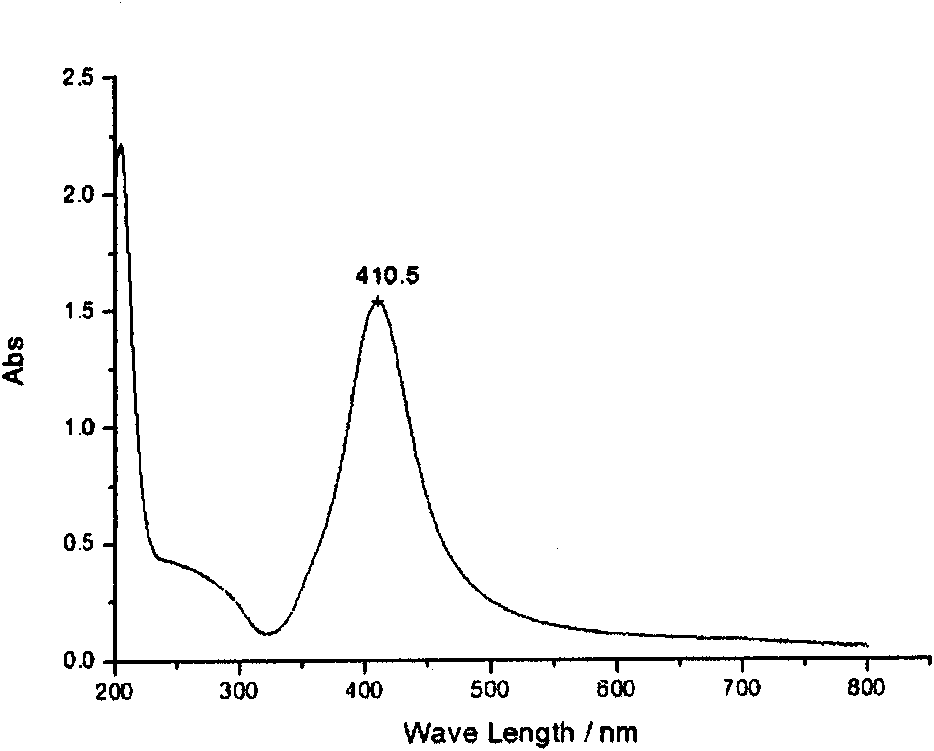

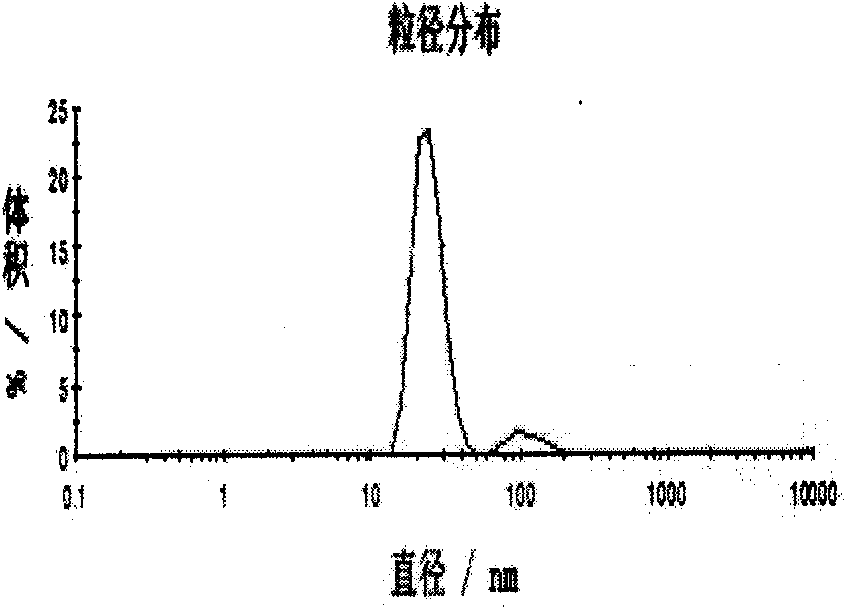

[0048] In the specific implementation of the present invention, the particle size is 20-400nm prepared by the method of reference "Preparation and Spectroscopic Analysis of Nano-Silver Conductive Film" (Mo Lixin, Li Luhai, Li Yaling, etc., Spectroscopy and Spectral Analysis 2007.12, P2502). Range of silver particle suspension, choose polyvinylpyrrolidone (PVP) as the dispersion stabilizer.

[0049]Get silver nitrate solution and hydrazine hydrate solution that equal volume concentration is 0.25mol / L the same, get PVP / silver nitrate (mass ratio)=1.75, make ink-jet ink nano-silver solid content be 1.2%, size be 50~100nm;

[0050] In the obtained nano-silver conductive particle emulsion, add a moisturizing agent, a pH regulator, a surfactant, and a binder according to parts by weight, stir for 30 minutes, and mix evenly; Membrane filtration, to obtain the inkjet conductive ink, its composition is shown in...

Embodiment 2

[0052] Embodiment 2 prepares nano-silver emulsion ink-jet conductive ink

[0053] Get the silver nitrate solution and the hydrazine hydrate solution that are the same volume concentration of 0.75mol / L, get PVP / silver nitrate (mass ratio)=2, make the nano-silver solid content of the inkjet ink be 3.6%. The size is 70-120nm. The preparation steps are the same as in Example 1, and the composition of the obtained inkjet conductive ink is shown in Table 3.

Embodiment 3

[0054] Embodiment 3 prepares nano-silver emulsion ink-jet conductive ink

[0055] Get the silver nitrate solution and the hydrazine hydrate solution that are the same volume concentration of 2.25mol / L, get PVP / silver nitrate (mass ratio)=4, make the nano-silver solid content of the inkjet ink be 10.9%. The size is 100-150nm; the preparation steps are the same as in Example 1, and the composition of the obtained inkjet conductive ink is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com