Single-spindle monocontrol intelligent air covered yarn machine

A single control, air bag technology, applied in the spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problem of not being able to produce different types of yarns at the same time, not adapting to flexible and small Issues such as mass production and low level of intelligence, to achieve fast and convenient process change or adjustment at any time, convenient storage and recall, and a strong sense of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

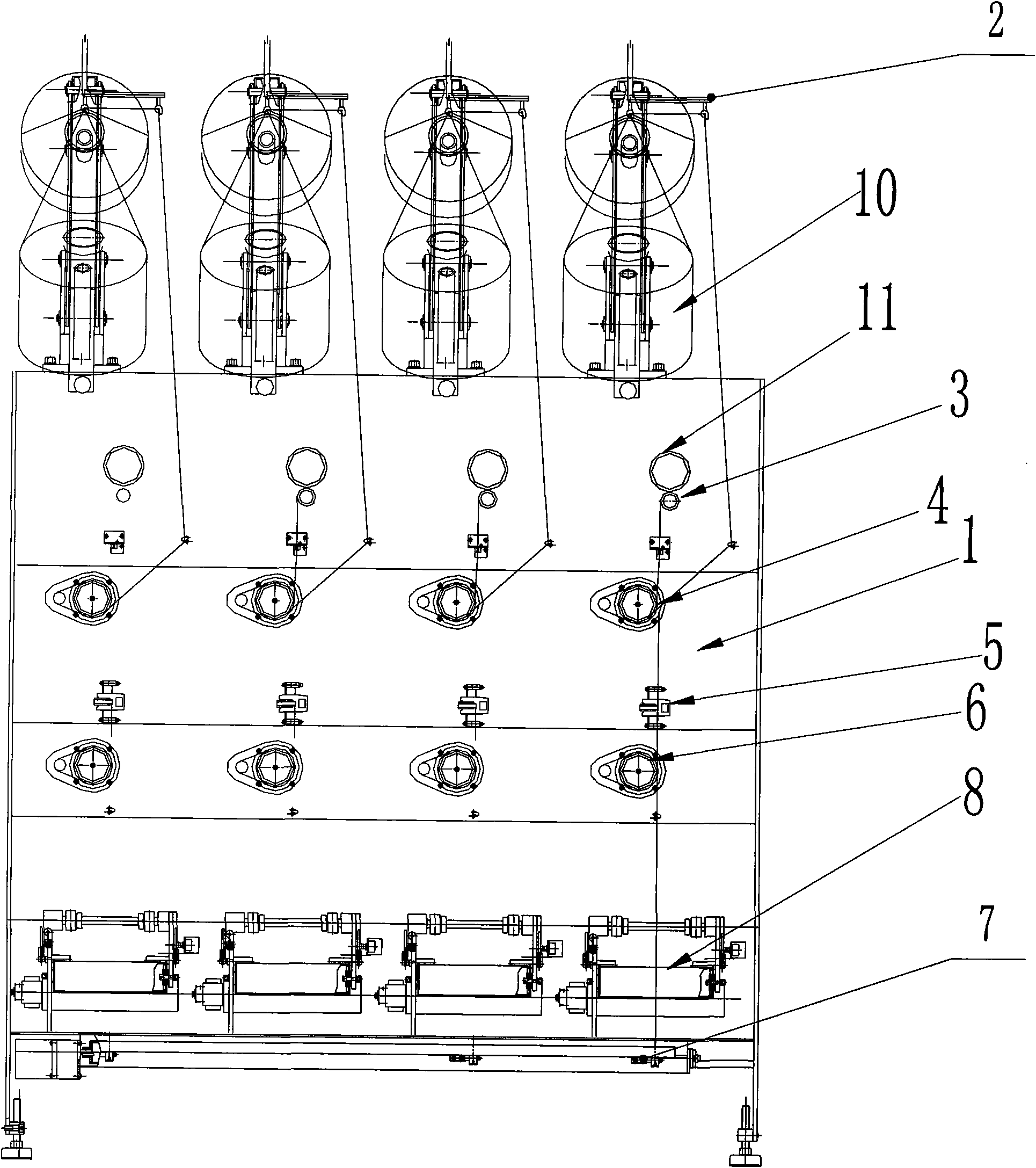

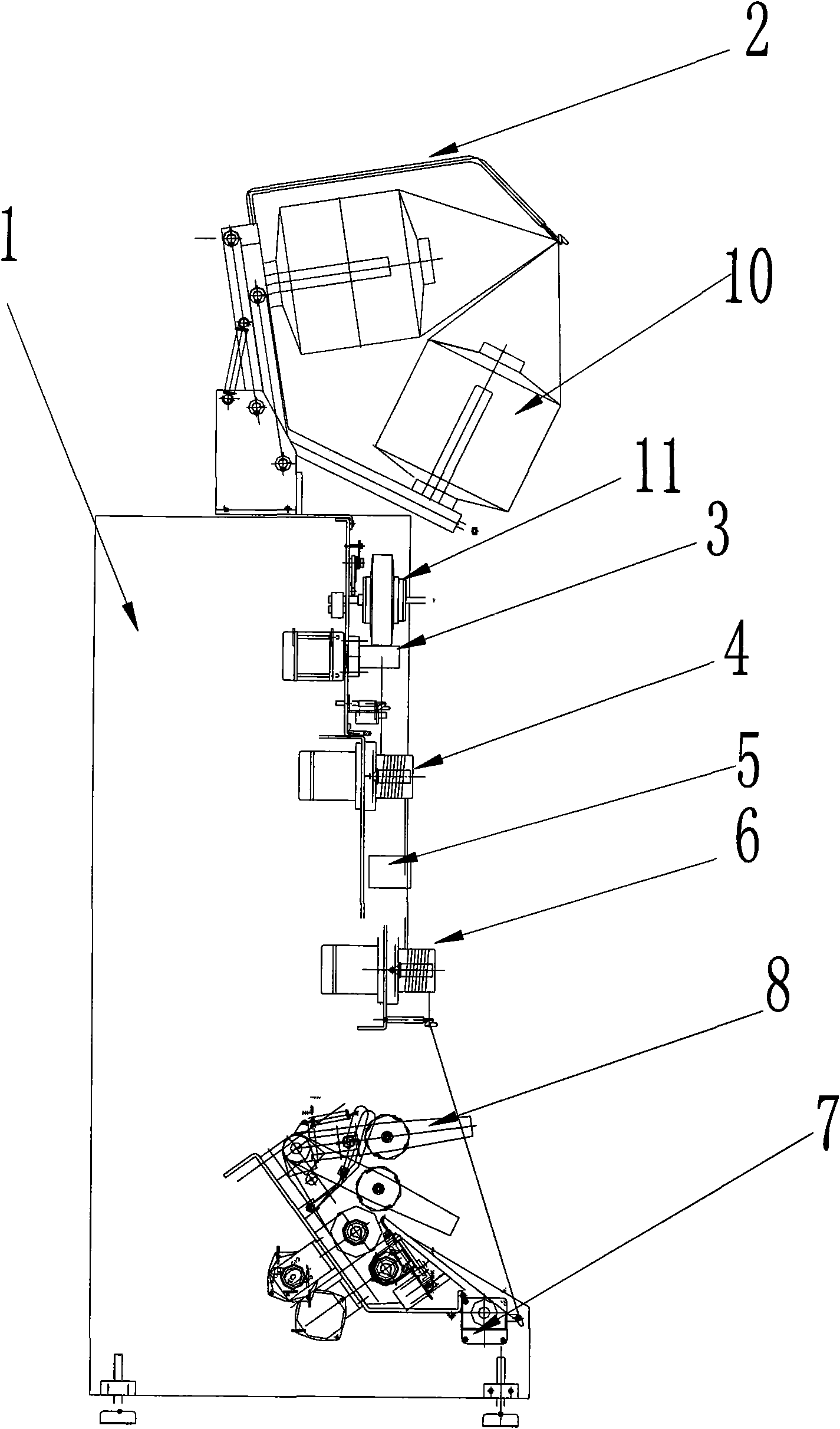

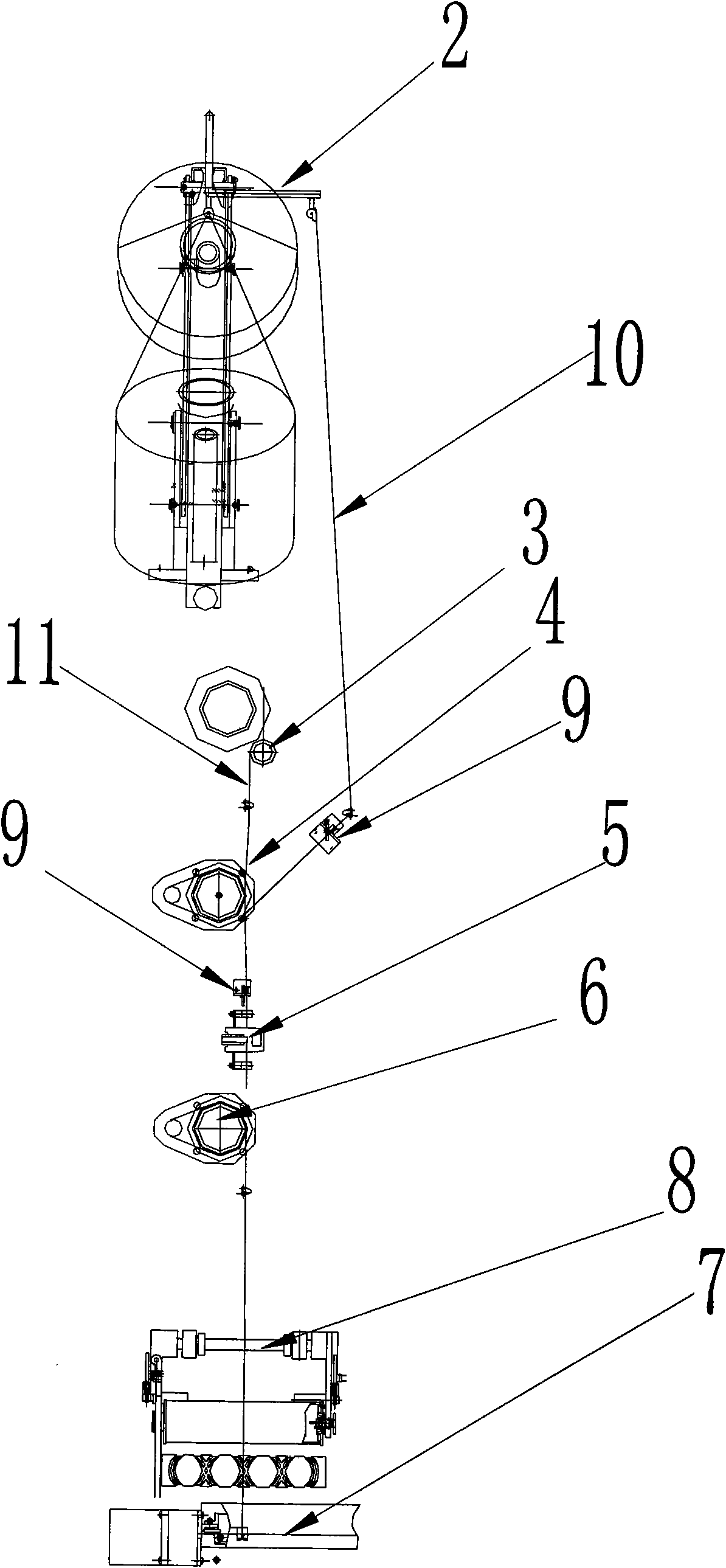

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a frame 1, an electrical control system and a multi-spindle covered yarn mechanism, and each spindle covered yarn mechanism includes an original creel 2, a spandex feeding device 3, a draft feeding device 4, and an air covering device 5. Main drafting device 6, automatic oiling device 7 and high-speed precision winding device 8, including: raw creel 2, spandex feeding device 3, draft feeding device 4, air covering device 5, main drafting device Device 6, high-speed precision winding device 8, and automatic oiling device 7 are arranged on frame 1 from top to bottom. Spandex feeding device 3, draft feeding device 4, air covering device 5, main drafting device 6, automatic oiling device 7 and high-speed precision winding device 8 are located on the front of frame 1, and the electrical control system is mainly distributed in the machine frame. Right behind the frame 1, each join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com