Device for continuously removing optical fiber coating and winding bare fiber

A coating and optical fiber technology is applied in the field of continuous removal of optical fiber coating for fiber optic gyroscopes and bare fiber winding devices, which can solve the problems of inability to meet the requirements of volume and weight miniaturization, and achieve the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

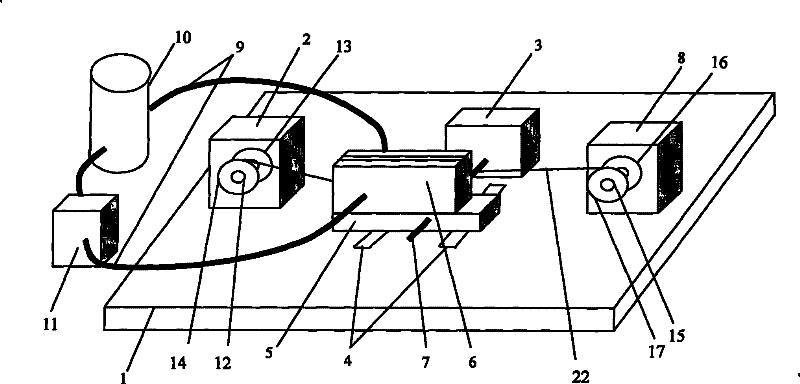

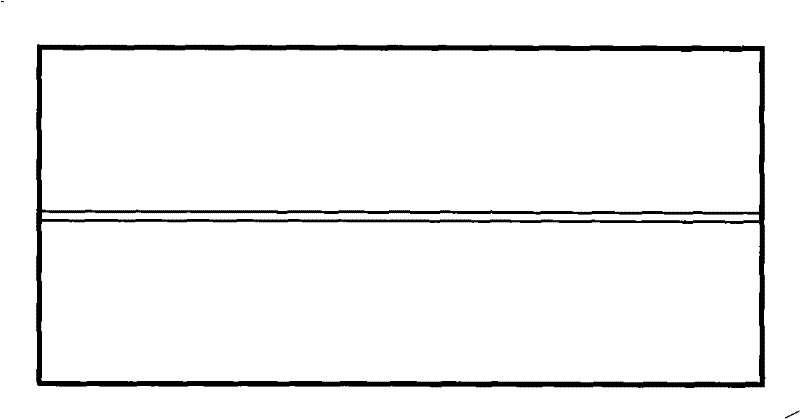

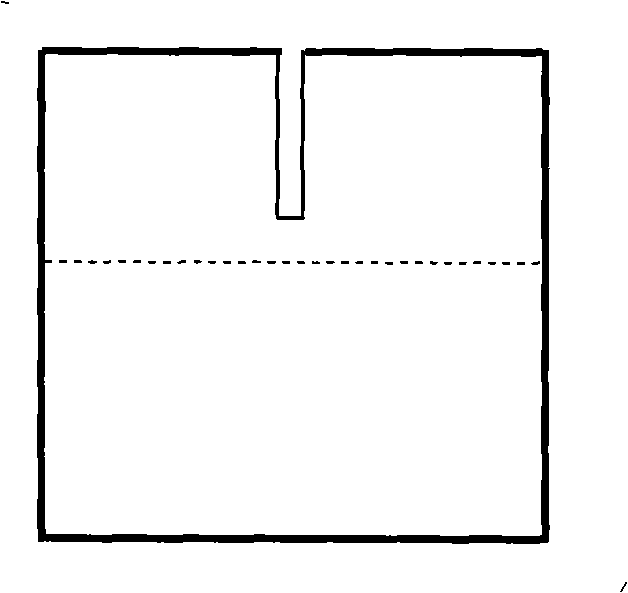

[0016] Such as figure 1 , 2, and 3, the continuous removal of the optical fiber coating layer and the bare fiber winding device for the optical fiber gyroscope are: the first motor 2, the second motor 3, the parallel guide rail 4, and the third motor 8 are installed in sequence on the base 1, A slide block 5 and a dissolving chamber 6 are successively installed on the parallel guide rail 4, and the dissolving chamber 6 is connected to the liquid container 10 and the liquid pump 11 through two liquid conduits 9; the first rotating shaft 12 is installed on the front side of the first motor 2, and the first The rotating shaft 12 is driven to rotate by the first motor 2, and the first baffle plate 13 and the backup ring 14 are installed on the first rotating shaft 12; the second rotating shaft 7 with thread is installed on the front side of the second motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com