Backlight module and liquid crystal display device using same

A technology for liquid crystal display devices and backlight modules, which is applied to lighting devices, components of lighting devices, optics, etc., and can solve problems such as low utilization efficiency of light energy, inability to meet the uniform light output of light sources at the same time, and inability to manufacture thin display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

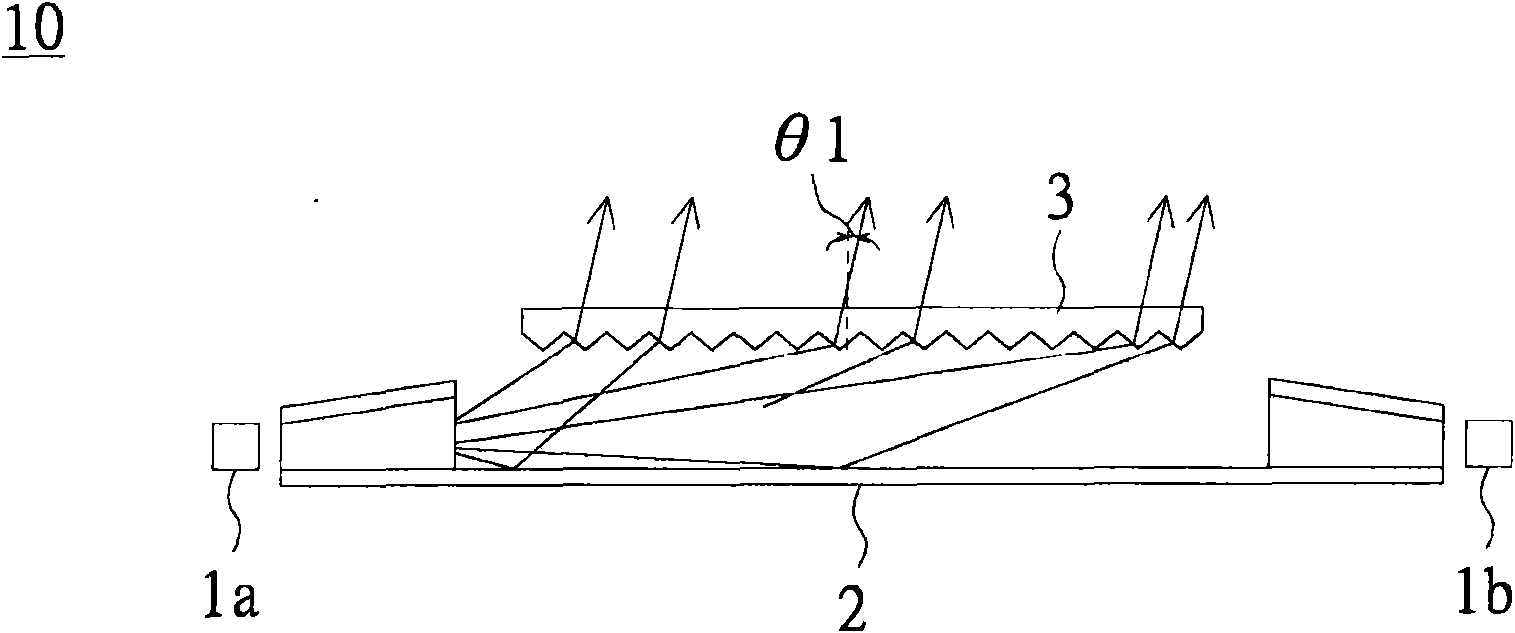

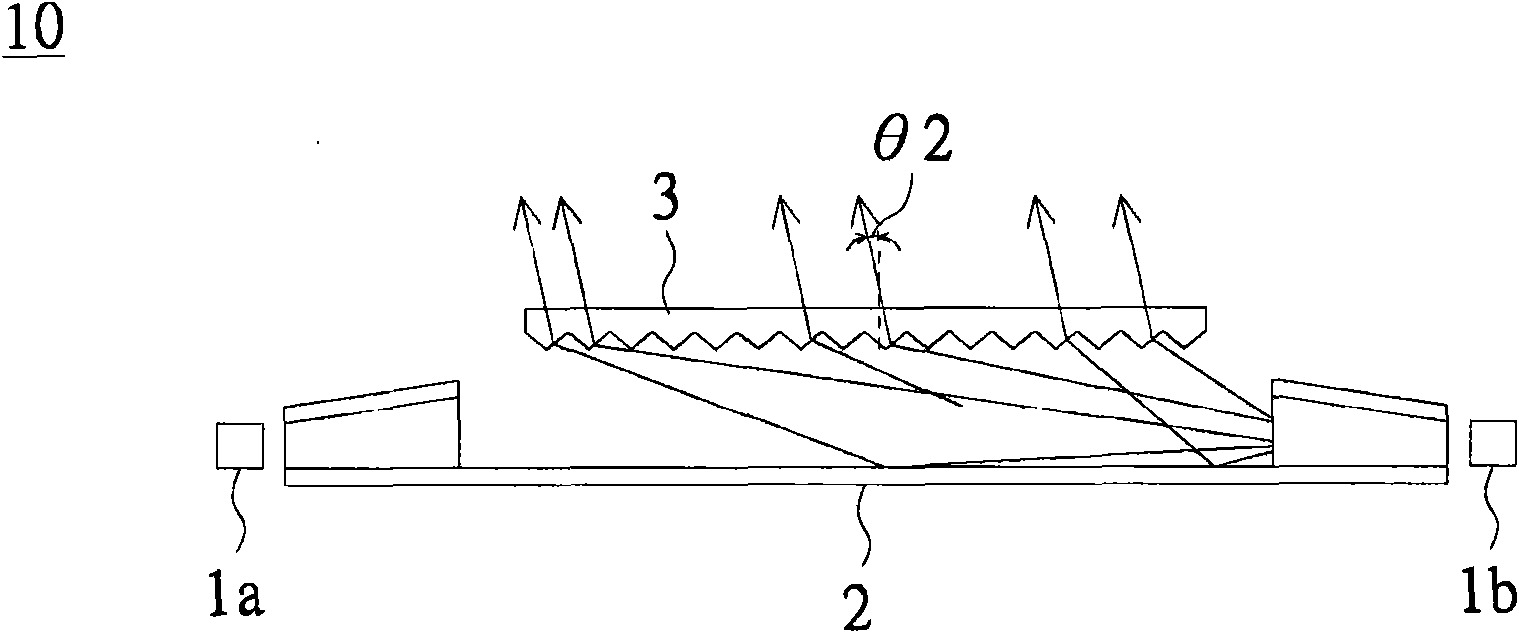

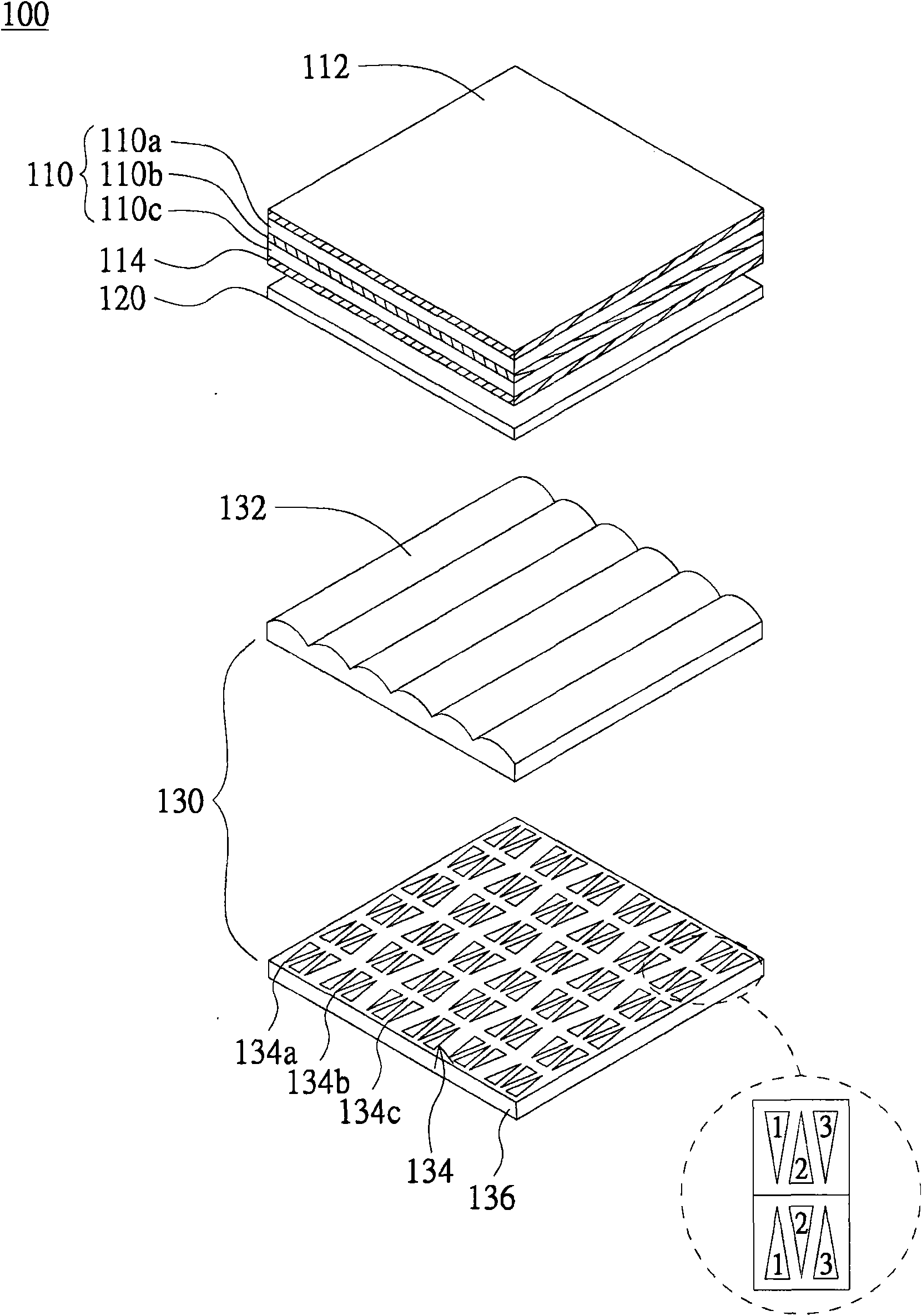

[0045] Please also refer to Figure 2A and Figure 2B , which respectively show an exploded perspective view and a side view of the liquid crystal display device of the first embodiment. The liquid crystal display device 100 includes a liquid crystal display panel 110 , an optical film 120 , a backlight module 130 and a power supply module (not shown). The upper polarizing film 112 and the lower polarizing film 114 are respectively attached to the upper surface and the lower surface of the liquid crystal display panel 110 . The liquid crystal display panel 110 includes a first substrate 110a, a liquid crystal layer 110b and a second substrate 110c, wherein the first substrate 110a is, for example, a color filter substrate, and the second substrate 110c is, for example, a thin film transistor substrate. The backlight module 130 is located under the liquid crystal display panel 110 , and the optical film 120 is located between the liquid crystal display panel 110 and the backl...

Embodiment 2

[0051] Please refer to image 3 , which shows a side view of the liquid crystal display device of the second embodiment. The main difference between the liquid crystal display device 200 of this embodiment and the liquid crystal display device 100 of the first embodiment is that the backlight module 230 includes a light source 234 and an optical switch element 233 . The rest of the elements that are the same as those in Embodiment 1 continue to use their symbols. The light source 234 is located on the substrate 236. In this embodiment, the substrate 236 is a back plate. The substrate 236 has a reflective layer 240 for reflecting the light source 234 to improve light energy utilization efficiency. The optical switch element 233 is located on the light source 234 , and the first light emitting unit 233 a and the second light emitting unit 233 b are evenly distributed on the optical switch element 233 . The light source 234 may be a light emitting diode (light emitting diode, L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com