Device for online monitoring and controlling residual service life of durable components of steam turbine and method

A steam turbine, durable technology, applied in the field of steam turbines, can solve the problems of creep life loss, unreasonable use of remaining life of durable parts of steam turbines, low cycle fatigue life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

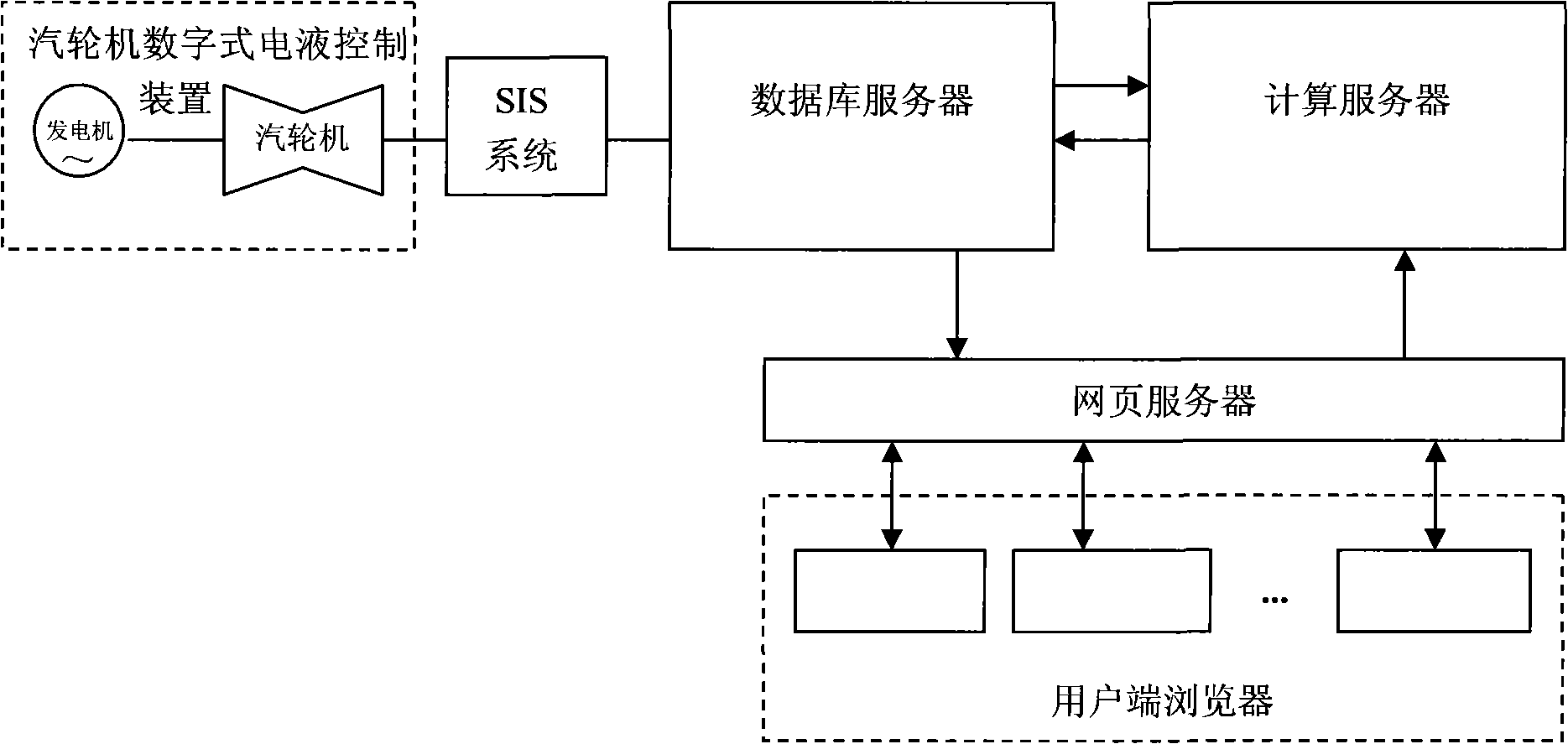

[0068] Such as figure 1 Shown is a block diagram of the online monitoring and control device used in the present invention. The online monitoring and control device for the remaining life of durable parts of the steam turbine consists of a computing server, a database server, a web server, a client browser, and plant-level monitoring information The device (SIS device) consists of the web server connected to the client browser, database server and computing server respectively, and the computing server is connected to the database server. The database server is connected to the plant-level monitoring information device (SIS device) and the steam turbine digital electro-hydraulic control device (DEH) connection.

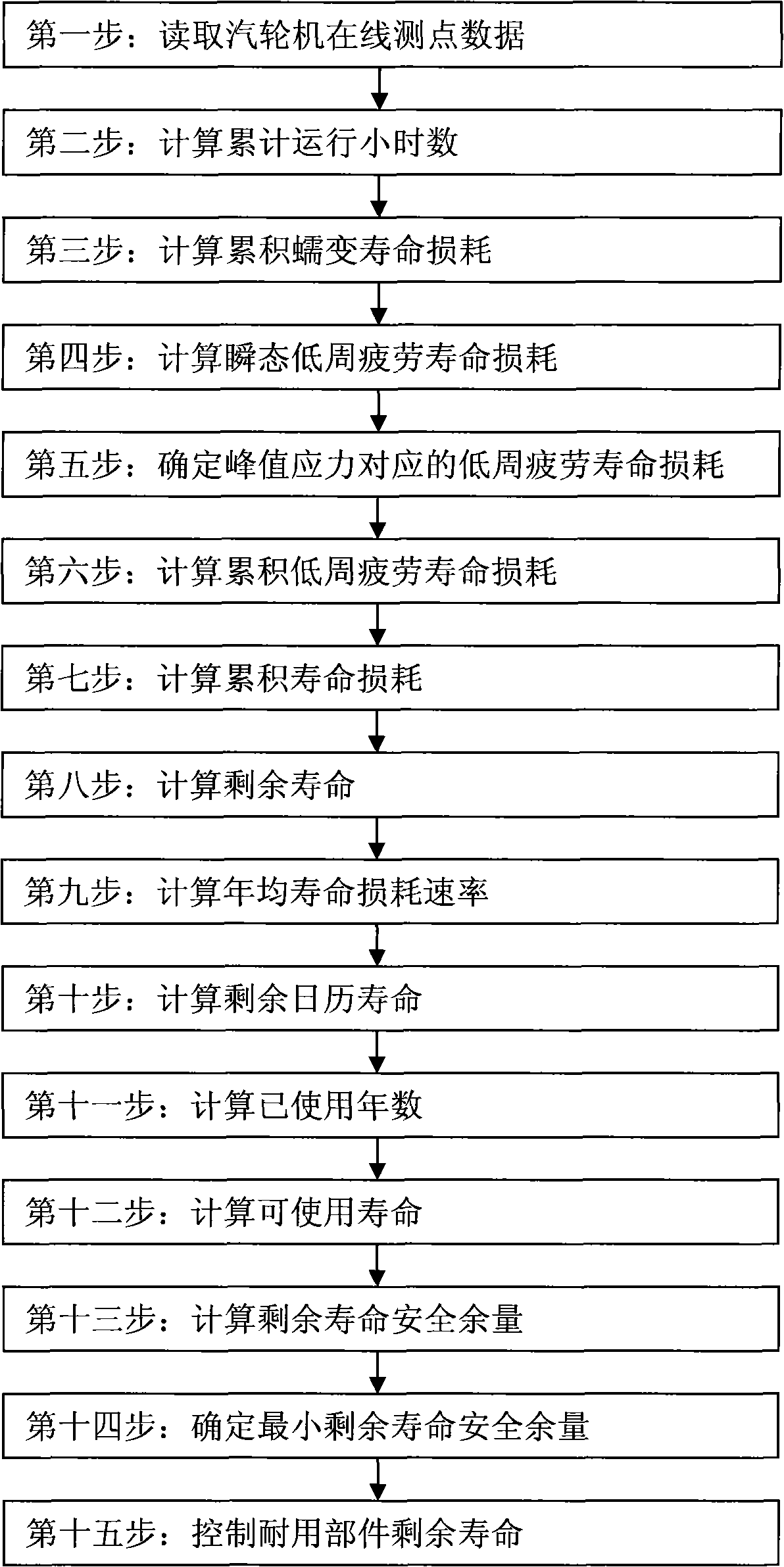

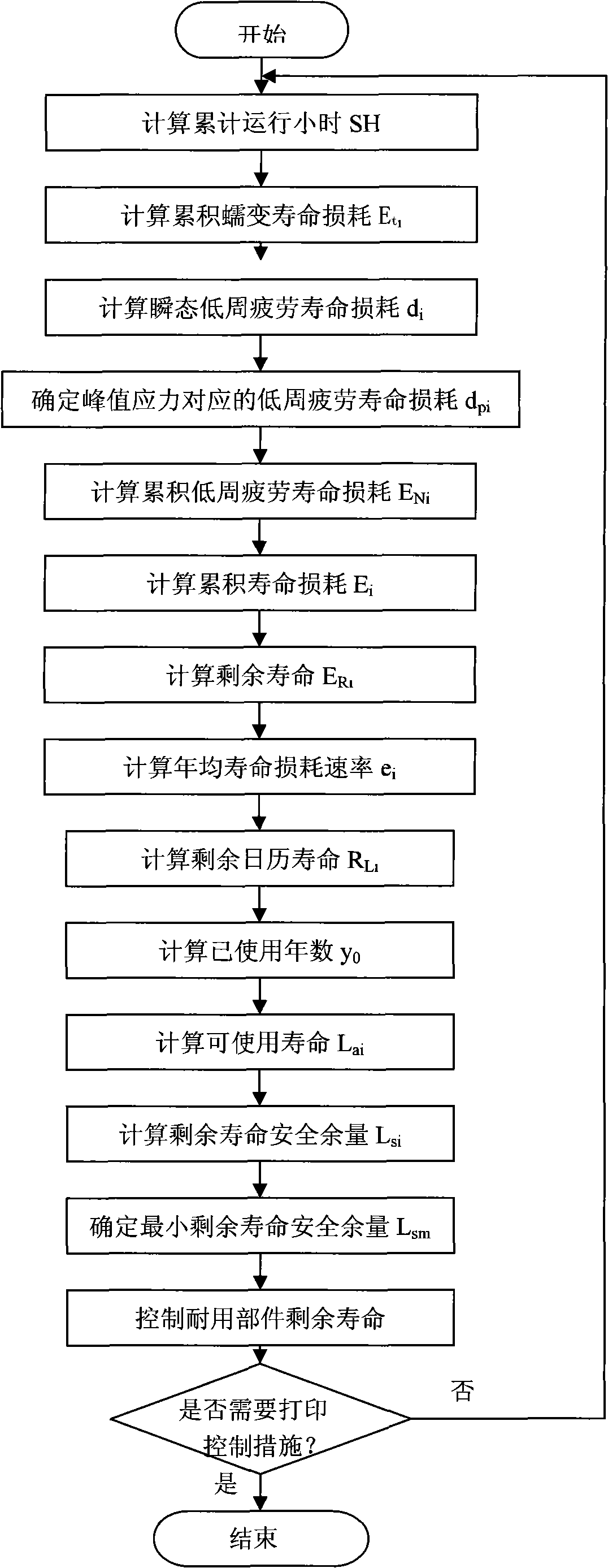

[0069] Such as figure 2 Shown is a flowchart of the method used in the present invention, such as image 3 Shown is a block diagram of the computer software used in the calculation server. The software is installed on the calculation server for the remaining life of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com