Organic electroluminescent luminous display and manufacturing method thereof

An electroluminescence and display technology, which is applied in the field of organic electroluminescence lighting displays and its production, can solve the problems of restricting the organic electroluminescence lighting display, the problem of heat dissipation of the lighting display, the problem of unsolvable short circuit defects of impurity particles, etc. , to achieve the effect of low power consumption, simple production and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

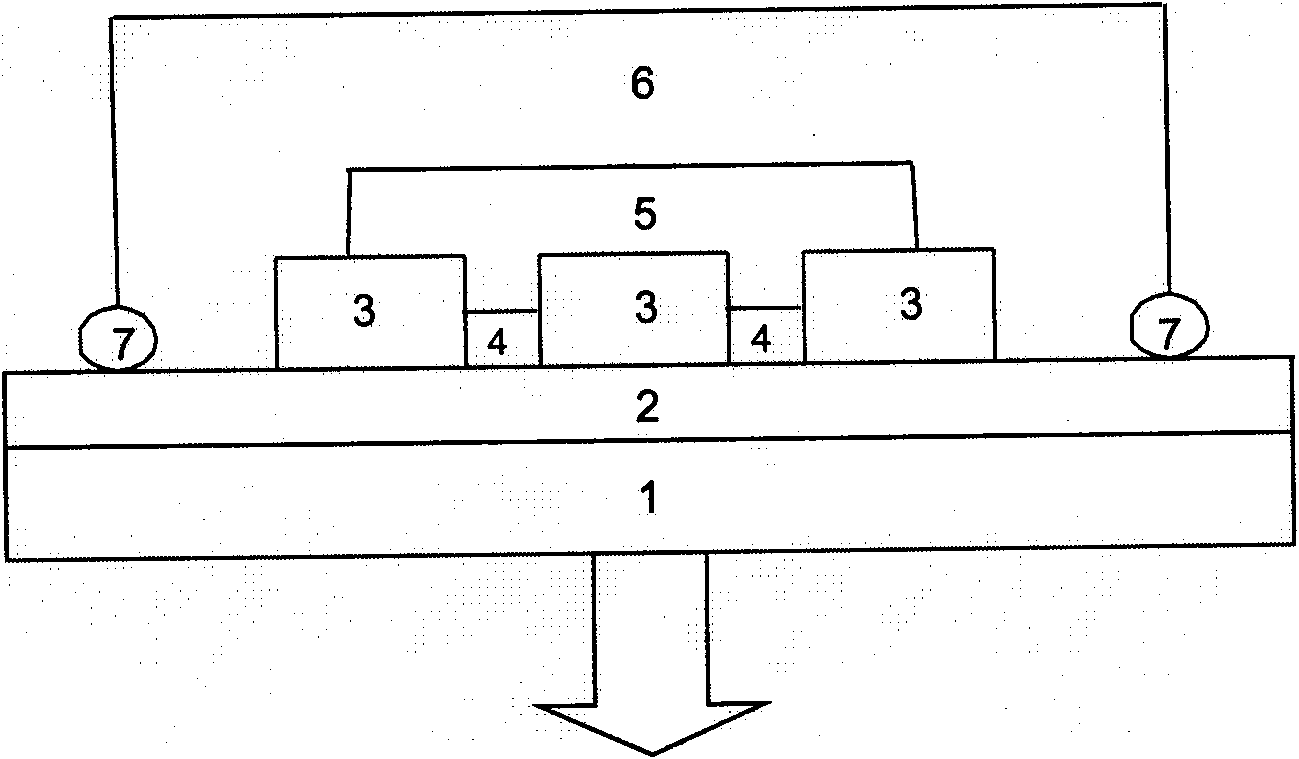

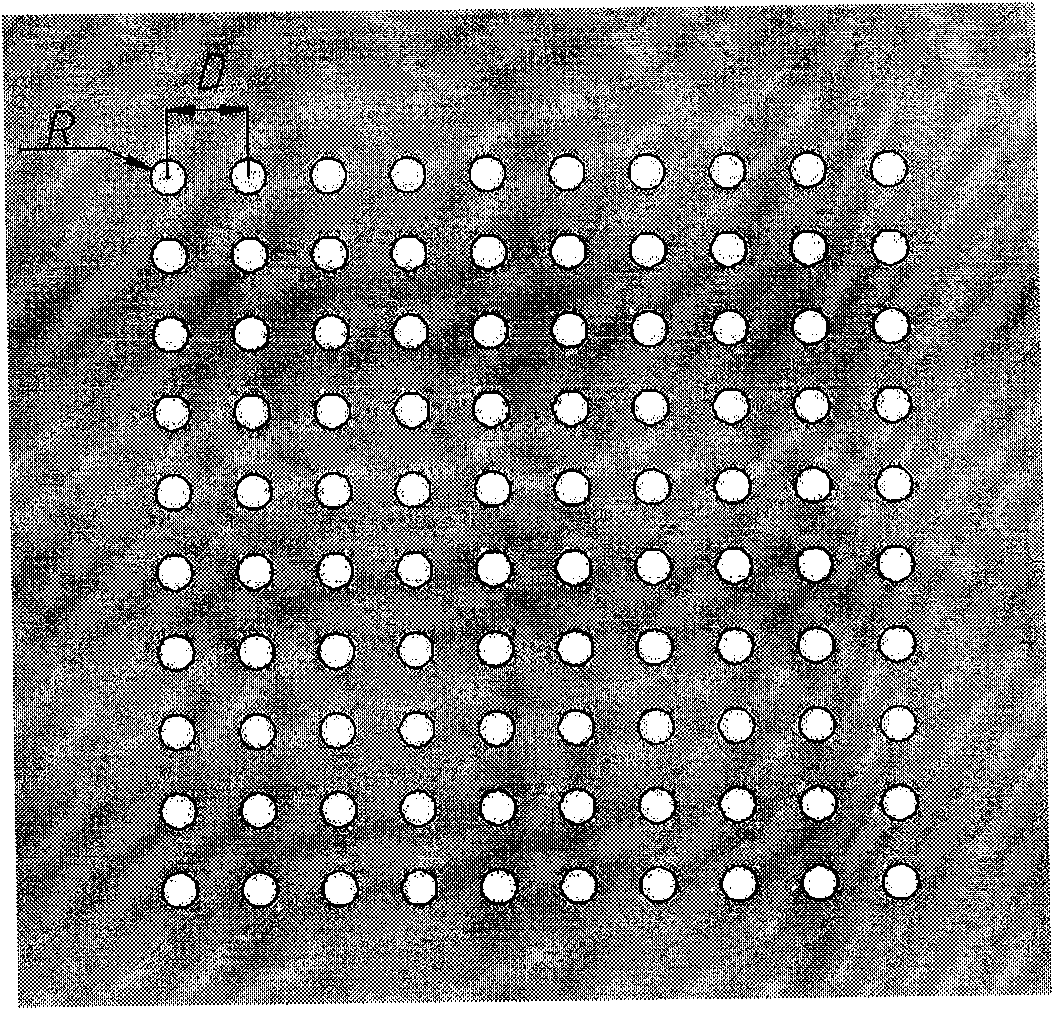

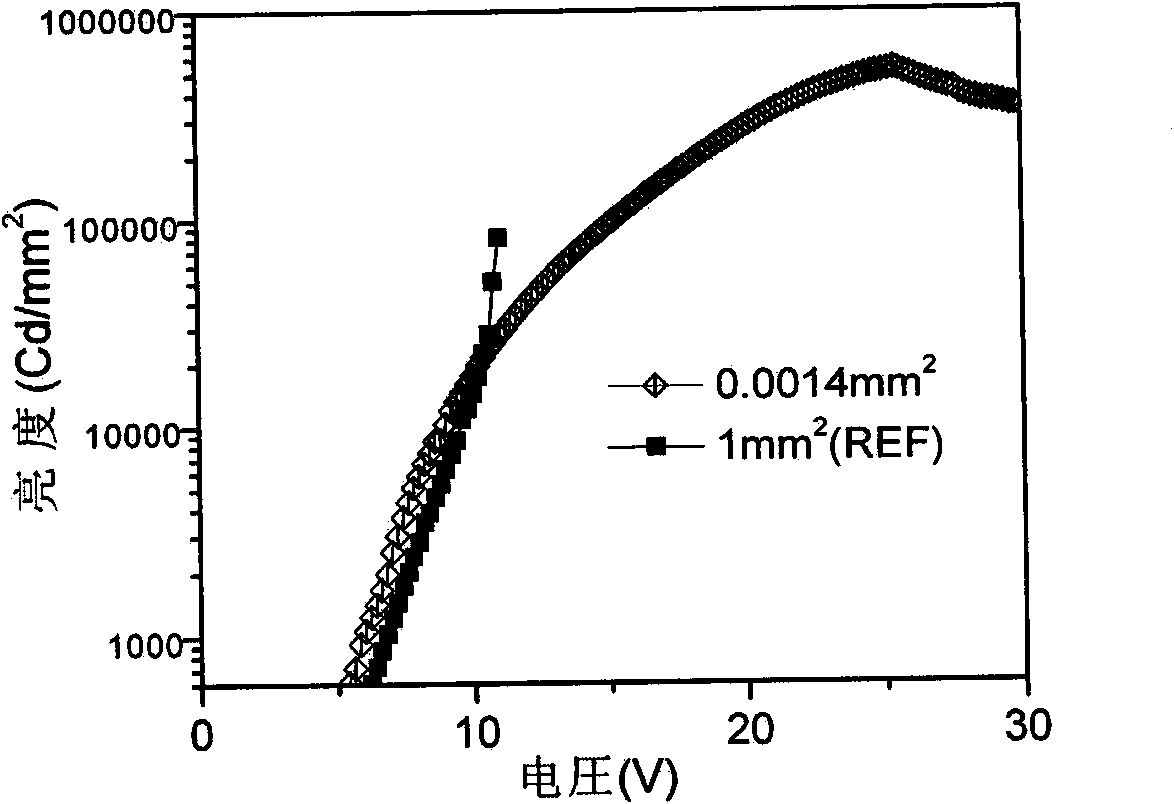

[0034] An imitation embodiment of the present invention is described as follows in conjunction with accompanying drawing: See figure 1 As shown, the display for organic electroluminescence lighting is formed by connecting glass 1 and cover 6 through encapsulation glue 7 . The ITO thin film 2 is fabricated on the glass 1 to form an ITO glass substrate. The conductive functional layer 3 is fabricated on the ITO thin film 2 to form a regular pattern of dot matrix distribution holes, and the organic material layer 4 is vapor-deposited in the regular pattern, and then the metal electrode layer 5 is vapor-deposited. By connecting the positive electrode ITO thin film 2 and the negative electrode metal electrode layer 5, the organic material layer 4 is driven to emit light by direct current.

[0035] The preparation method of the display for organic electroluminescent lighting: make a patterned heat-conducting functional layer on an ITO glass substrate, deposit an organic material la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com