Marsh liquid filter

A technology of filter and biogas slurry, which is applied in the direction of fixed filter element filter, filtration and separation, chemical instruments and methods, etc., can solve the problems of biogas slurry viscous slag, and the filter is easy to be blocked, so that it is not easy to block and easy to use The effect of long life and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

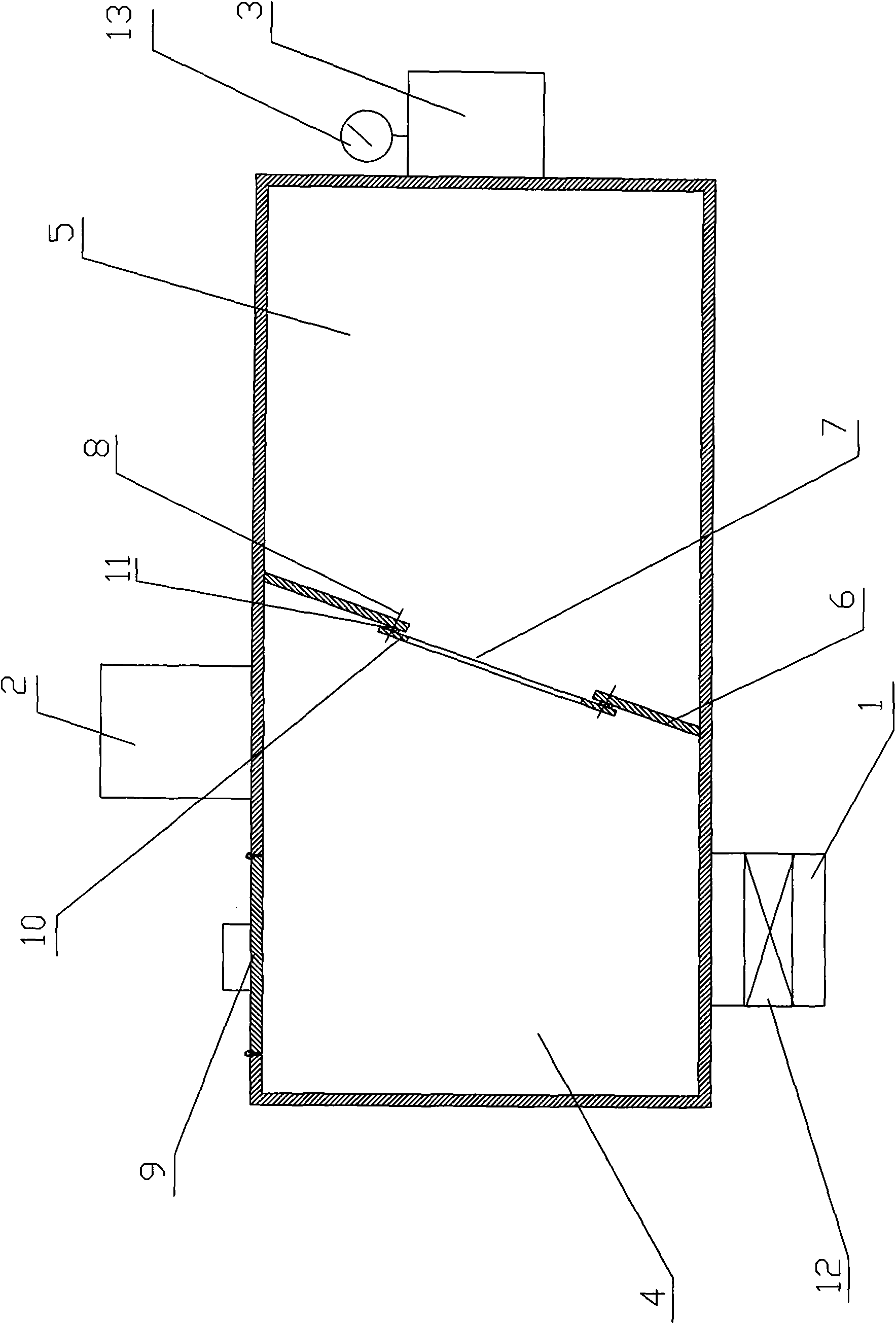

[0020] Such as figure 1 As shown, the biogas slurry filter includes a biogas slurry chamber 4 and a clear solution room 5 separated by a filter screen 7 and distributed horizontally. The upper end of the biogas slurry room 4 is connected with a biogas slurry inlet pipe 2, and the clear solution room 5 is connected with a filtrate outlet pipe 2, which is characterized in that: the filter screen 7 forms an acute angle with the biogas slurry inlet pipe 2, the biogas slurry inlet pipe 2 is close to and faces the filter screen 7, and the bottom of the biogas slurry chamber 4 is also A slag liquid outlet pipe 1 is connected. The invention adopts a horizontal structure, so that the biogas slurry passes through the oblique impulse force of the biogas slurry inlet pipe to the filter screen and the pressure generated by the difference in diameter between the biogas slurry inlet pipe and the slag liquid outlet pipe can be filtered and the filter screen is washed clean by the biogas slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com