Normally closed braking mechanism for crawler type traveling machine

A braking mechanism and crawler-type technology, applied in brakes, motor vehicles, crawler vehicles, etc., can solve the problems of machinery and operator danger, and achieve the effect of ensuring safety and reliable parking brake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

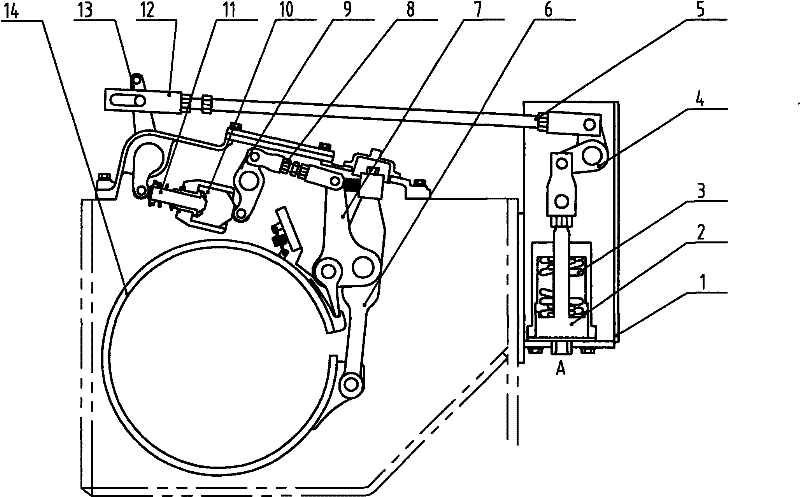

[0015] refer to figure 1 , the normally closed braking mechanism of the crawler-type walking machinery involves the original brake. The structure of the brake is: it has an outer rocker arm 13, the inner end of the outer rocker arm 13 presses the front piston 11, and the front piston 11 presses the rear piston 10. , the rear piston 10 presses one end of the middle rocker arm 9, the other end of the middle rocker arm 9 is hinged to one end of the middle inner connecting rod 8, the other end of the inner connecting rod 8 is hinged to one end of the inner rocker arm 7, and the inner rocker arm 7 There are two other hinge points, one of which hinges the support arm, and the other hinge point is hinged with the brake band connecting rod 6, and the front end of the support arm is supported on one end of the brake band 14, and one end of the brake band link 6 Hinged with the other end of brake band 14. In addition, a bracket 1 is provided on which an oil cylinder 2 is fixed. The oil...

Embodiment 2

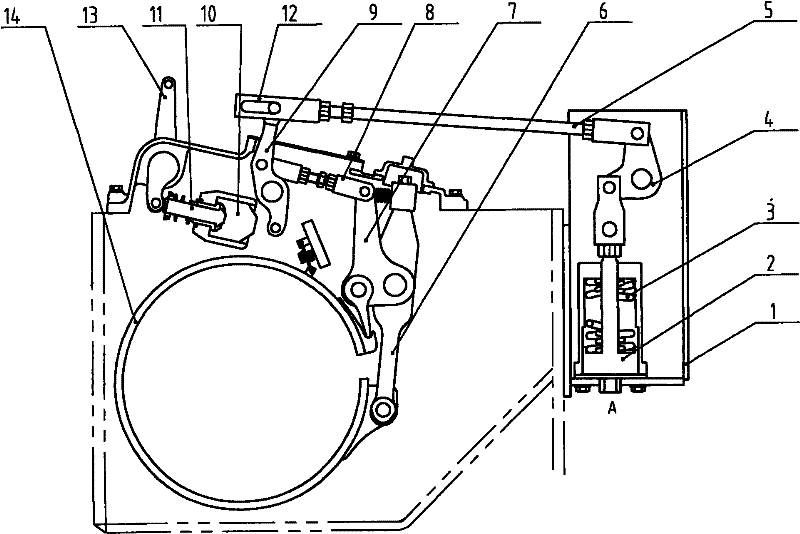

[0018] refer to figure 2 , the normally closed braking mechanism of the crawler-type walking machinery involves the original brake. The structure of the brake is: it has an outer rocker arm 13, the inner end of the outer rocker arm 13 presses the front piston 11, and the front piston 11 presses the rear piston 10. , the rear piston 10 presses one end of the middle rocker arm 9, the other end of the middle rocker arm 9 is hinged to one end of the middle inner connecting rod 8, the other end of the inner connecting rod 8 is hinged to one end of the inner rocker arm 7, and the inner rocker arm 7 There are other two hinge points, one of which is hinged with a support arm, the other hinge point is hinged with the brake band connecting rod 6, the front end of the support arm is supported on one end of the brake band 14, and the brake band link 6 One end is hinged with the other end of the brake band 14, and the difference is that the middle rocker arm 9 has an end extending out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com