Method and device for detecting forming evenness of recombinant material slab

A detection device and detection method technology, applied in the direction of measuring device, adopting mechanical device, analyzing materials, etc., to achieve the effect of simple process, solving uneven paving of slabs, and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

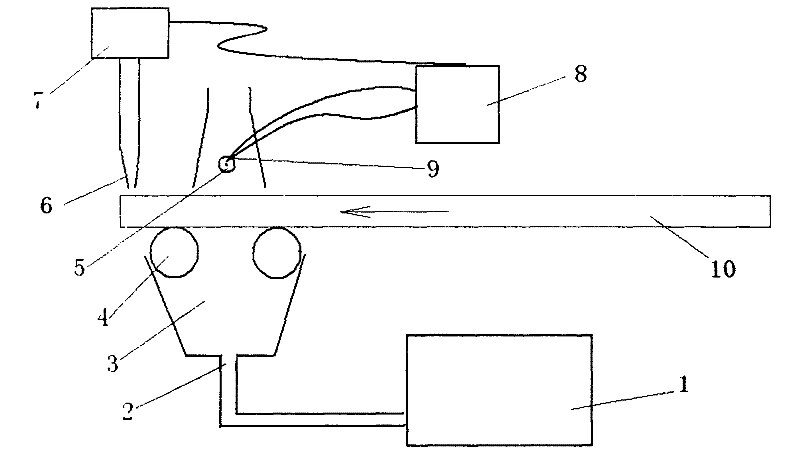

[0021] Provide specific embodiments below in conjunction with accompanying drawings.

[0022] Embodiments of the present invention are specifically as figure 1 shown. After the paved detection slab 10 is sent to the detection position, the blower 1 of the blowing part sends the air to the blowing cavity 3 through the pipe 2, and the pressing roller 4 made of rubber prevents the air from leaking out; blows the air into the recombined material Slab; use the detection sensor 9 of the detection part and the detection control instrument 8 to detect the position where the air velocity is too high, and the pavement density of the slab at this position is low; Spray marks, after the inspection is completed, fill the mark with appropriate raw materials to make up evenly to form a hot-pressed slab.

[0023] Other embodiments of the invention.

[0024] For different raw material forms, changing the distance between the detection sensor and the marking nozzle, such as 5 cm, 8 cm, to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com