Heat loss self-compensating terminal type water load microwave high power meter

A technology of automatic compensation and water load, which is applied in the direction of temperature compensation modification, thermometers and thermometers using electric/magnetic elements that are directly sensitive to heat, and can solve problems such as microwave power meter errors and high-power microwave test heat loss errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

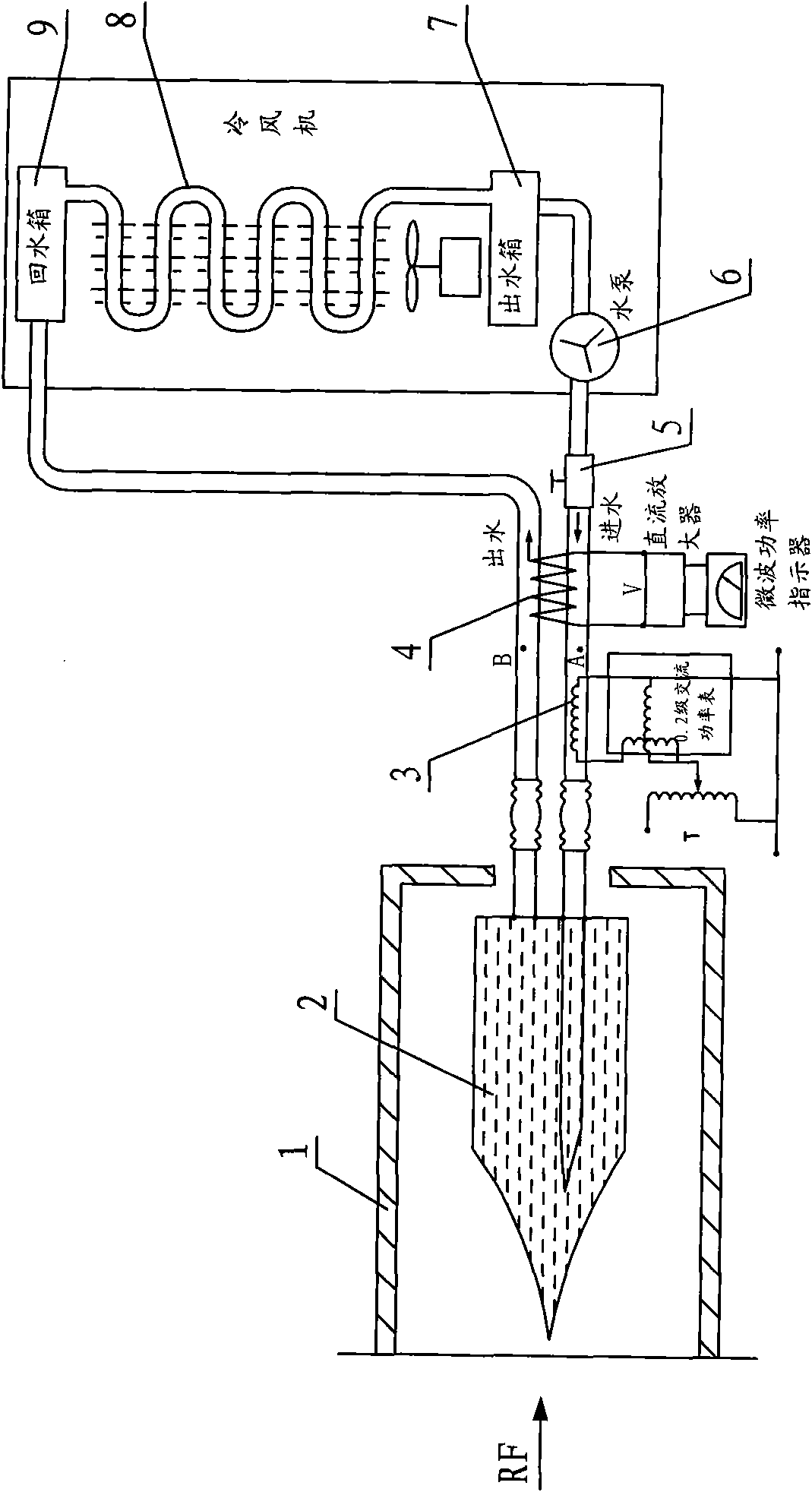

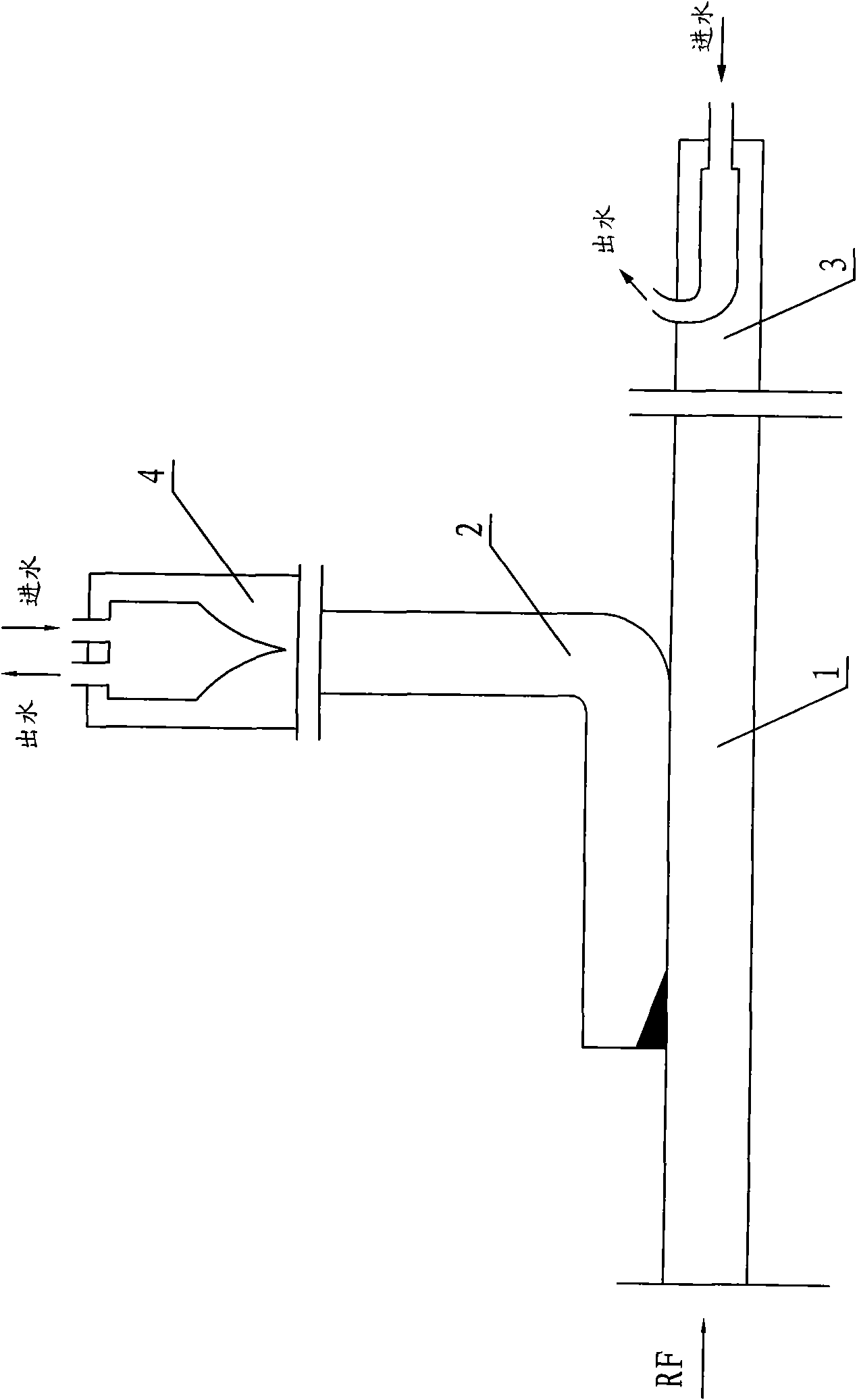

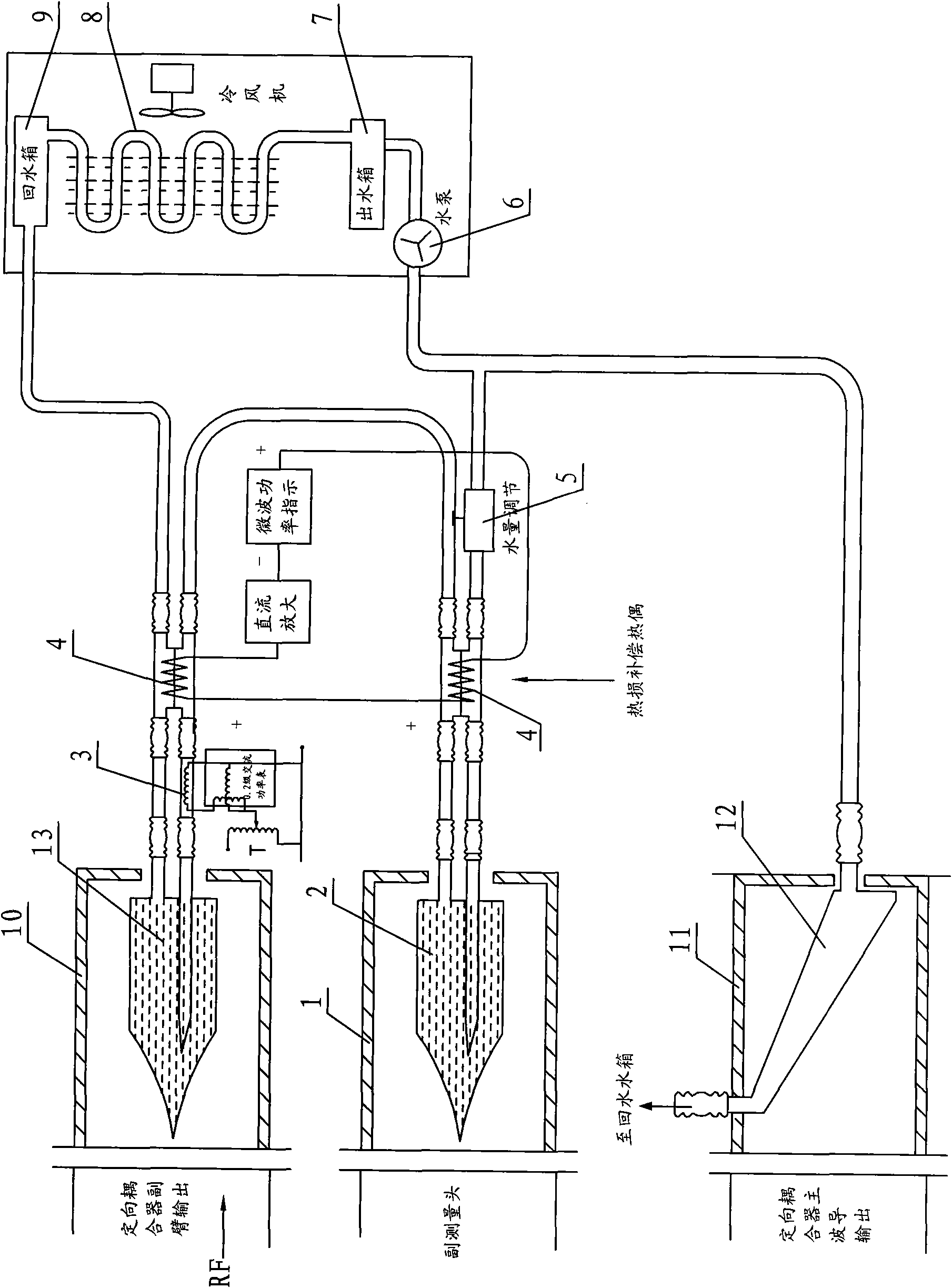

[0041] see image 3 , the water supply system of the present invention includes: a return water tank 9, a cooling pipe 8, a water outlet tank 7, a water pump 6, a water volume regulating valve 5, a terminal load 11, a waveguide load body 12, and the waveguide load body 12 is connected to the return water tank 9 of the water supply system; The test system includes: a test head 1 , a quartz glass body 2 , an adjustable AC electric heater 3 , a temperature difference sensor 4 and a signal detection circuit 14 . The temperature difference sensor 4 is a thermocouple.

[0042] On the basis of the prior art, the present invention adds a heat loss compensation system, which consists of a test head 10, a quartz glass body 13, and a temperature difference sensor 41; the water outlet of the test system is connected with the water inlet of the heat loss compensation system through the temperature difference sensor 41, and the After passing through the quartz glass body 13, it flows back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com