Pulling plate operating device for pot-type carbon calciner

An operating device and calciner technology, applied to lighting and heating equipment, fibrous packing, etc., can solve the problems of poor labor protection conditions for workers, large temperature differences between fire channels, and inaccurate adjustments, so as to improve the level of labor protection and reduce the size of the furnace. Effect of temperature difference and improvement of energy saving level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

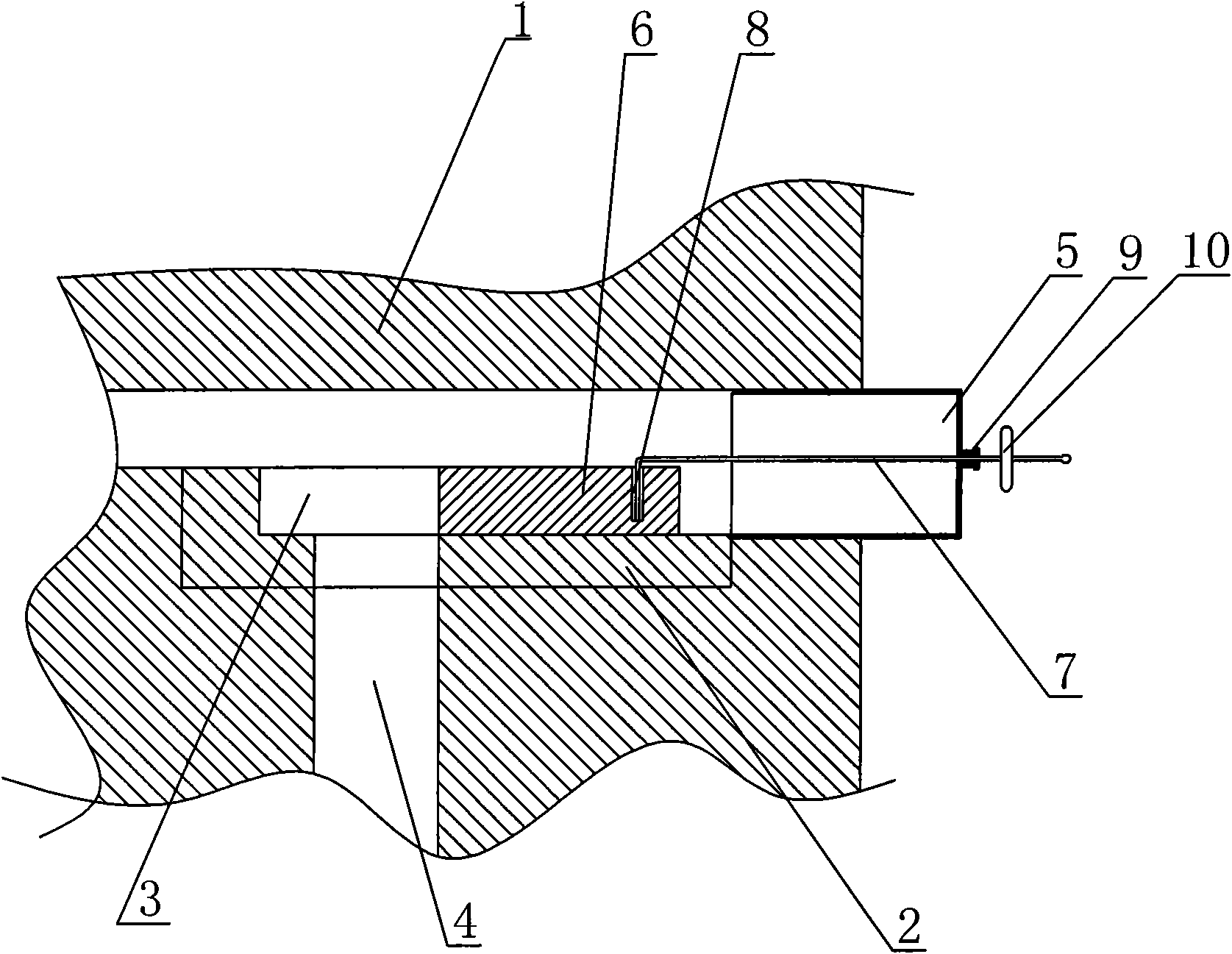

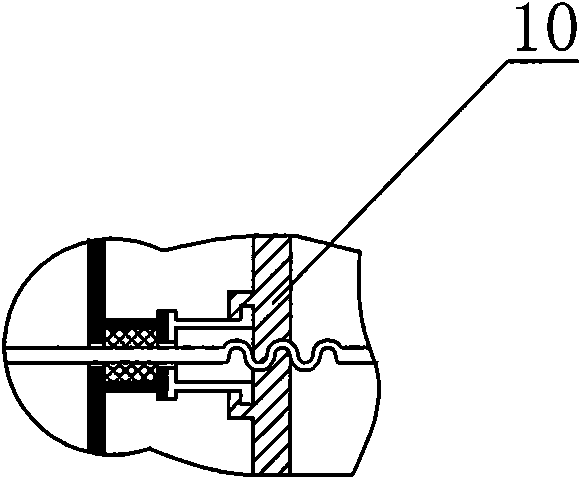

[0030] like figure 1 and figure 2 As shown, the pull plate operating device of the tank type carbon calciner of the present invention is built in the furnace wall masonry 1, the pull plate seat brick 2 is integrated with the furnace wall masonry 1, and the pull plate seat brick 2 is provided with Through hole 3, the through hole 3 is a rectangular hole, circular hole or polygonal hole, the side length or diameter of the through hole ranges from 30 to 300mm, the through hole 3 communicates with the volatile component or the hot air channel 4, and the through hole 3 communicates with the volatile component Or the hot air channel 4 is aligned with the masonry, and a guide groove is provided on the drawing board seat brick 2. The depth of the guide groove is 10-150 mm. The section of the hole 8 is circular, rectangular or polygonal. The diameter or side length of the push-pull hole 8 ranges from 3 to 60 mm, and the depth of the push-pull hole 8 ranges from 5 to 120 mm. Hook, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com