Anti-frozen-heaving heat pipe

A technology for preventing frost heave and heat pipes, which is applied to heating devices, heat exchange equipment, solar thermal devices, etc., can solve problems such as failure to work normally, heat pipe failure, and damage to solar water heating devices, and achieve the effect of solving the defects of frost heave cracked pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

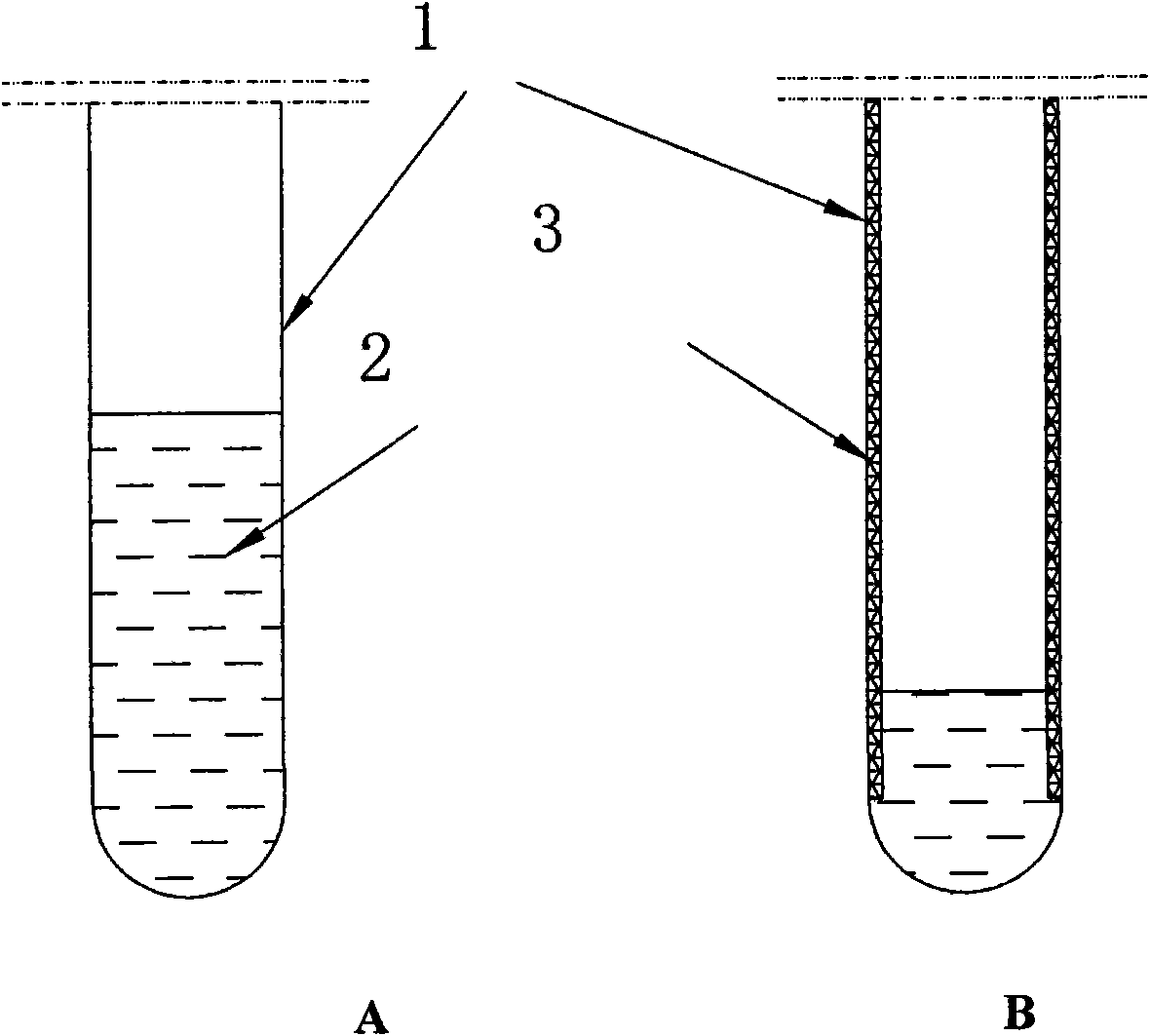

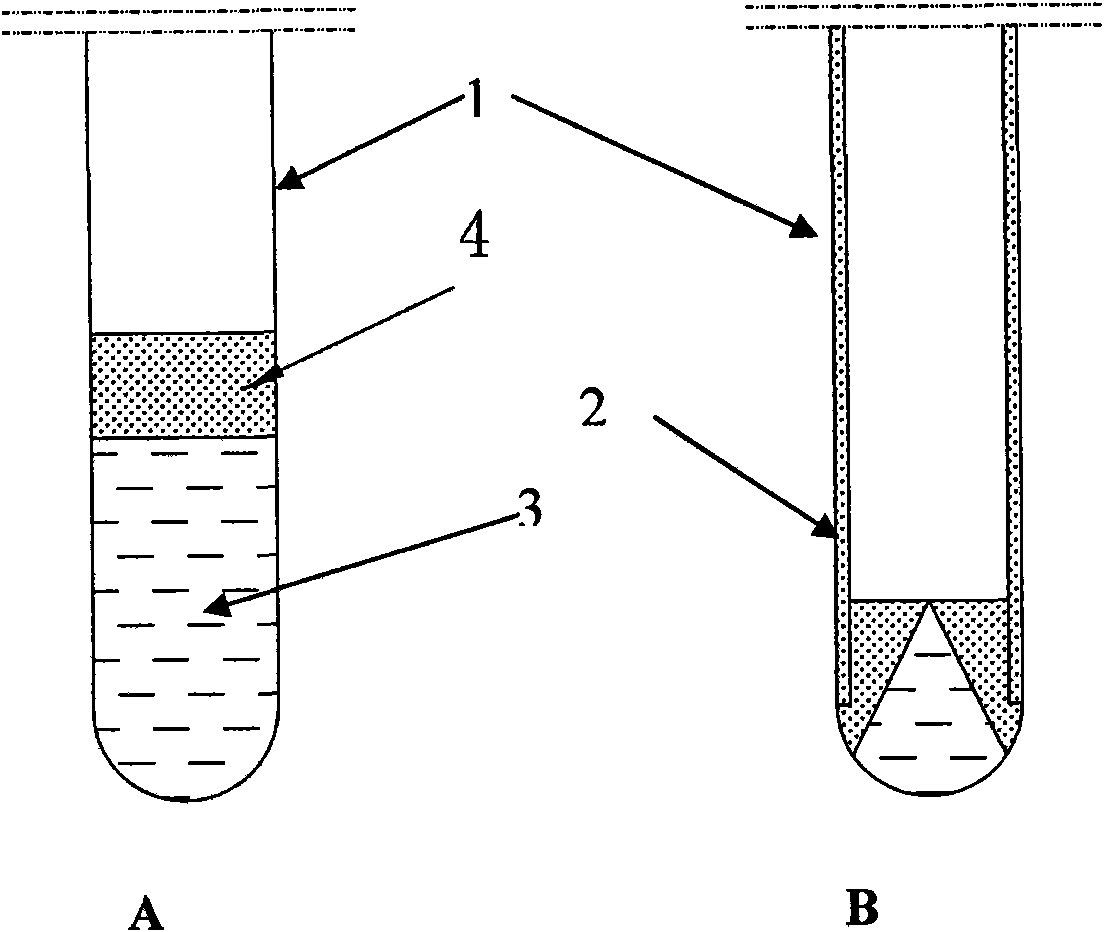

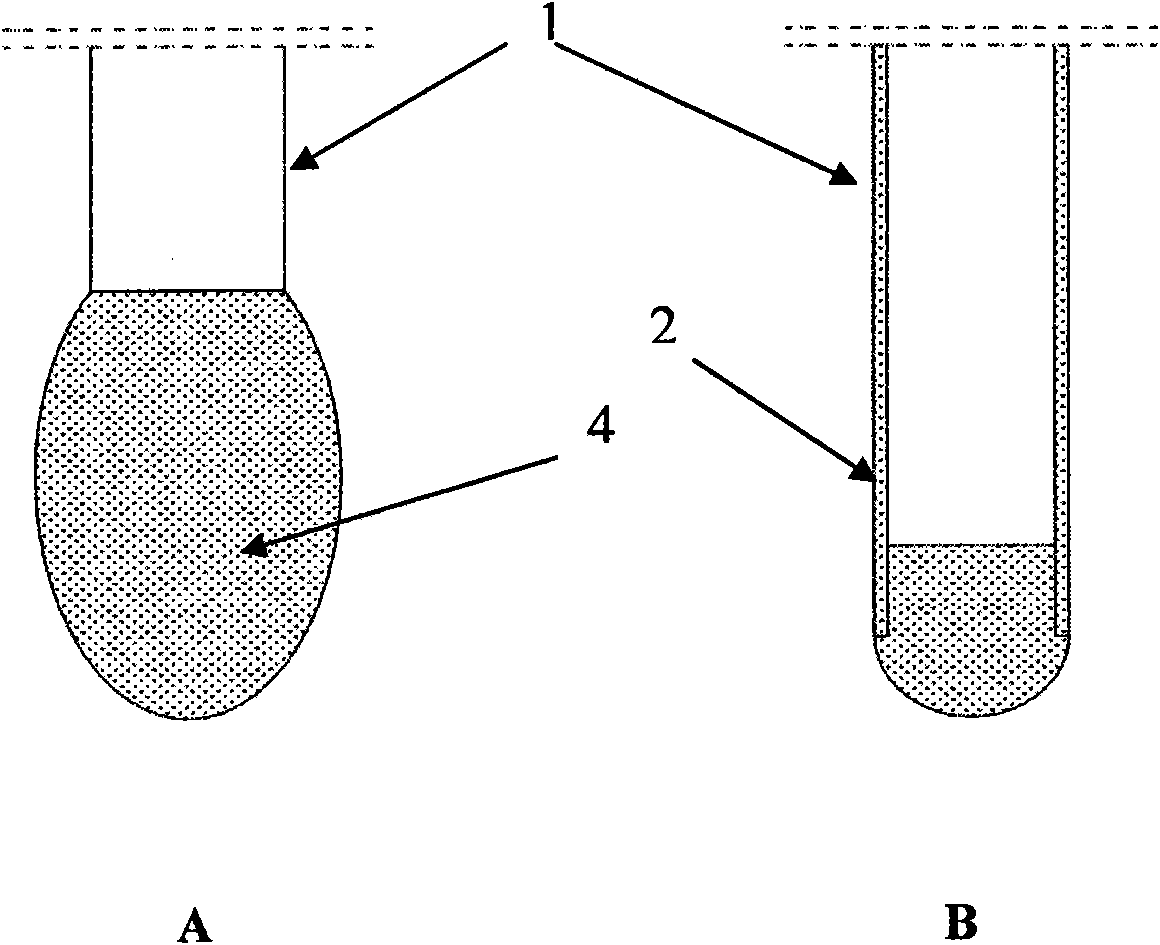

[0027] In the tube wall 1 (inner wall) of the evaporation section of the heat pipe, there is a liquid 2, namely water, at the bottom; the porous medium structure 3 is arranged in the evaporation section of the heat pipe, close to the tube wall 1, and one end, that is, the lower end, goes deep into the liquid 2, and the upper end is higher than or Much higher than the liquid level of liquid 2, that is, the liquid level of liquid 2 when the heat pipe stands vertically at normal temperature.

[0028] One of the porous medium structures 3 is a wire mesh 3 (also known as a liquid-absorbing core structure), the wire mesh 3 is in close contact with the tube wall 1 of the evaporation section, and the wire mesh 3 is made of copper wire; similar structures formed by sintering .

[0029] The second part of the porous medium structure 3 is a channel 6, and a plurality of channels 6 are engraved on the tube wall 1 of the heat pipe evaporating section. In the liquid 2 at the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com