Measurement method of axial size of abrupt-change cross section of revolving body

A technology of axial dimension and rotary body, applied in the field of rapid measurement of axial dimension, to achieve the effect of simple measurement procedure, easy data processing and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

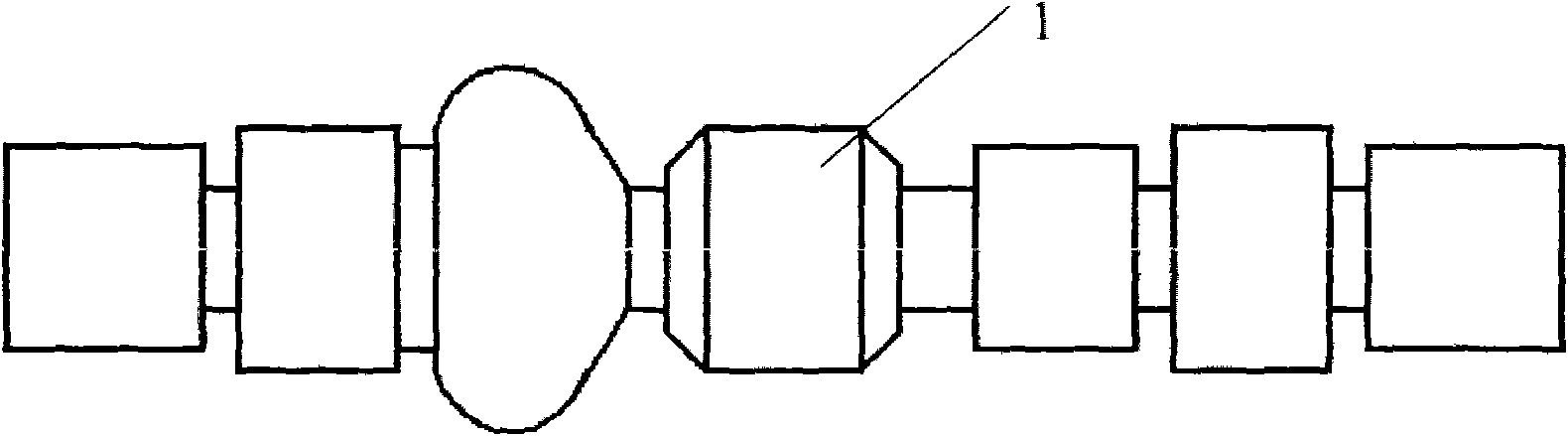

[0030] Use the method of the present invention to measure such as figure 1 The measured slewing body shown needs to measure the axial size of each abrupt cross-section. The steps are as follows:

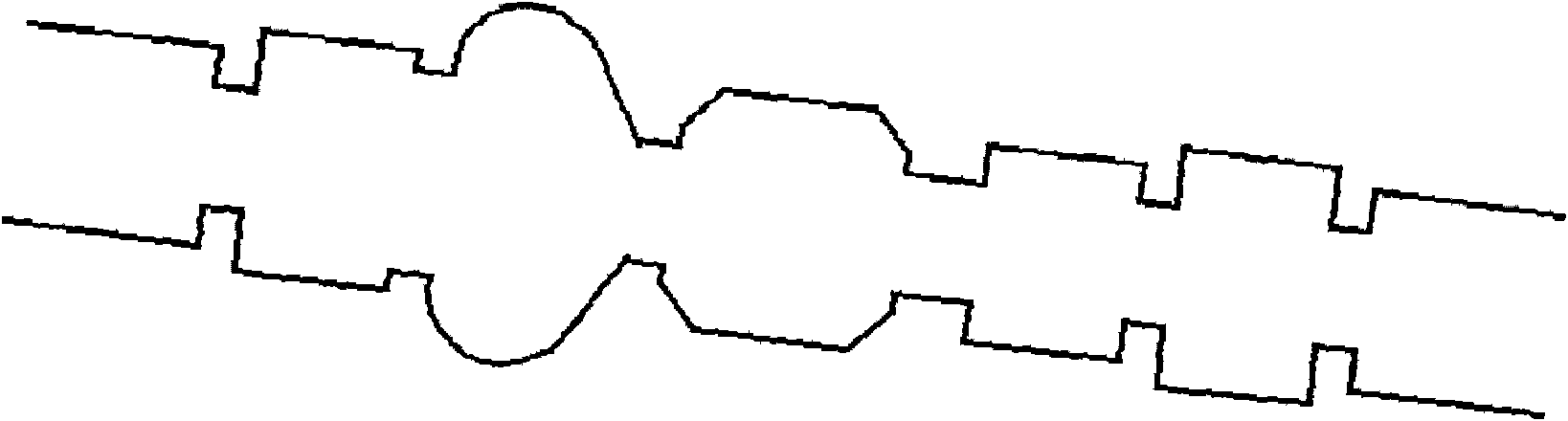

[0031] 1. The high-precision linear array CCD sensor and the parallel light emitter are located on the symmetrical sides of the rotating body, the contour of the rotating body is imaged on the CCD, and the optical image processing technology is used to output two measured values in the radial direction of the rotating body at this point When the CCD sensor moves along the axial position in sequence, two contours of the revolving body are obtained, which constitute a longitudinal section of the revolving body. Due to the installation error of the revolving body, the shape of the revolving body obtained by the measurement has a certain tilt, such as figure 2 Shown.

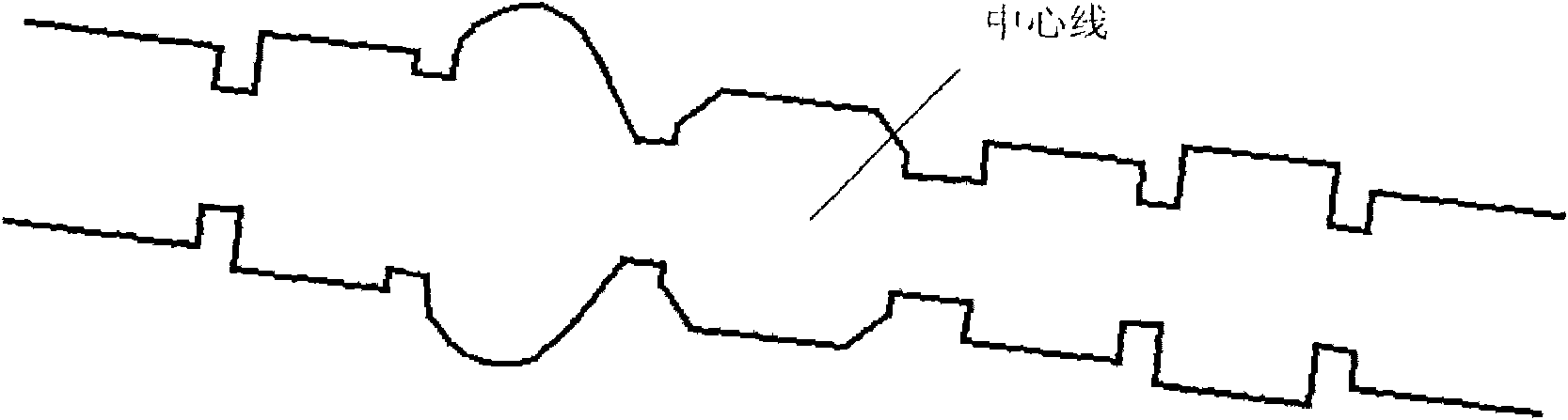

[0032] 2. According to the measured longitudinal section profile data, find the symmetry axis of the two busbars, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com