Weighing method of dynamic self-discharging car scales

A dump truck and weighing technology, which is applied in the field of weighing, can solve the problems of not being able to control the loading capacity in time, not being able to measure the weight of the loaded goods, and not being able to guarantee the speed and accuracy of dynamic weighing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

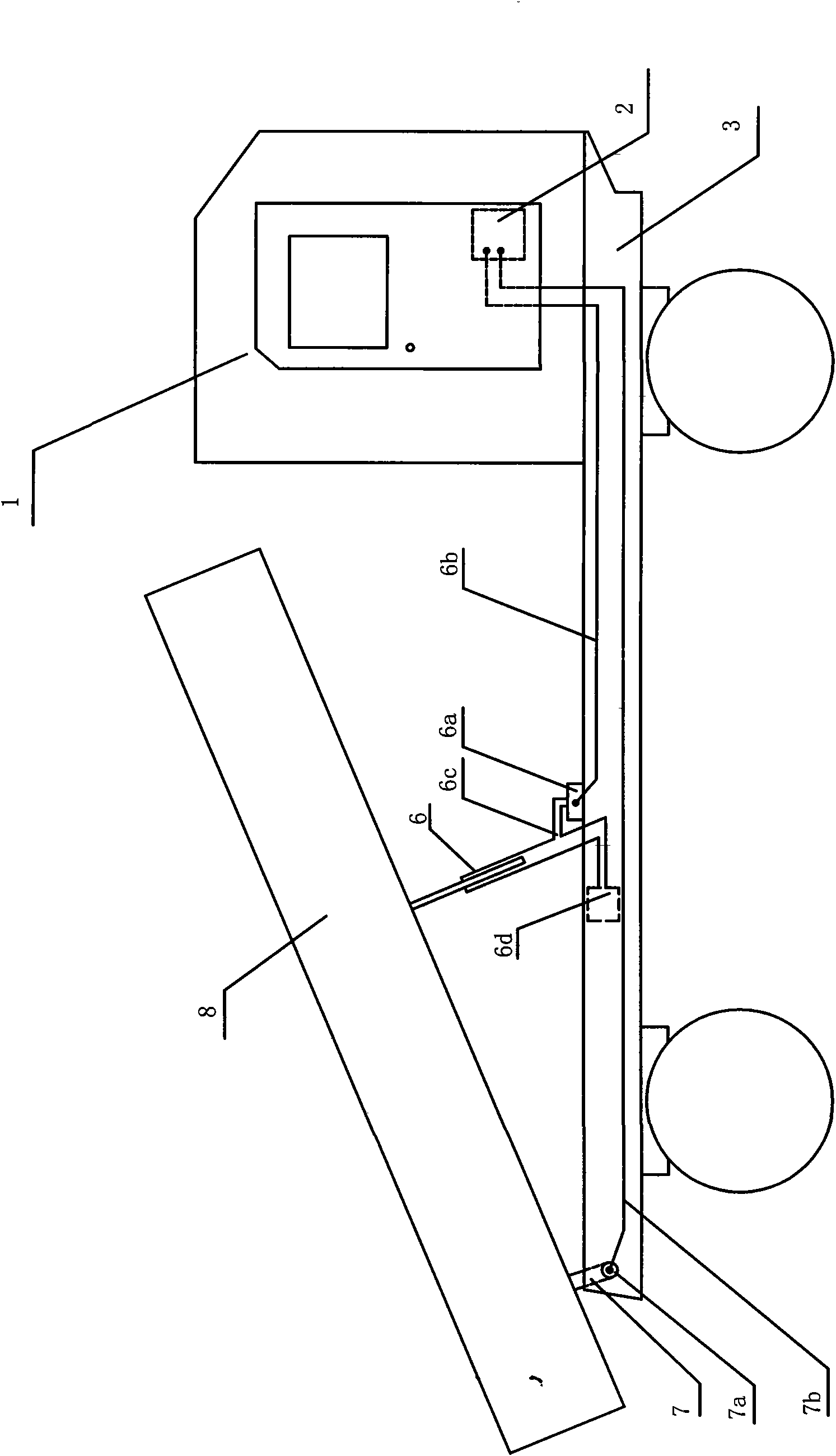

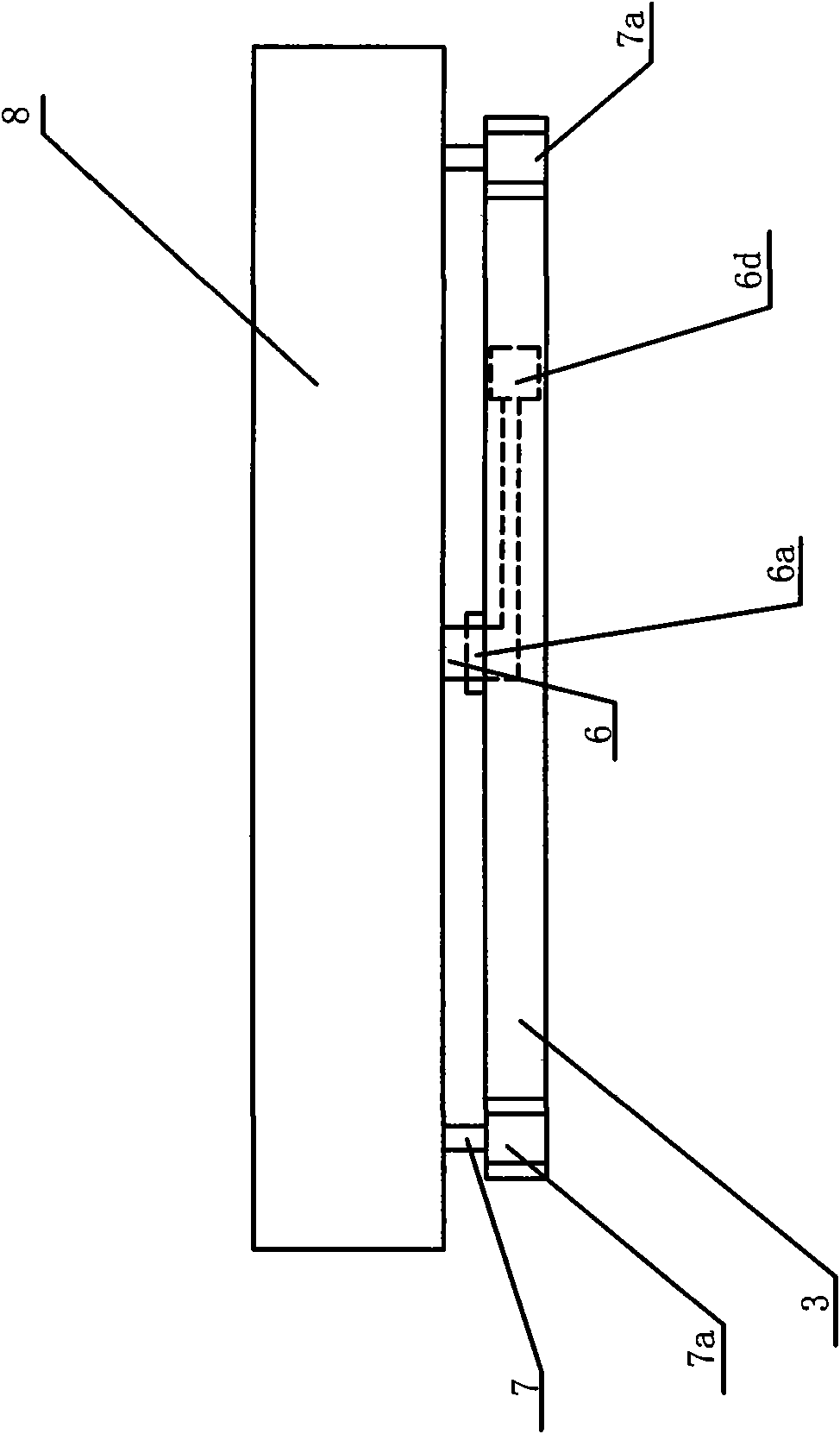

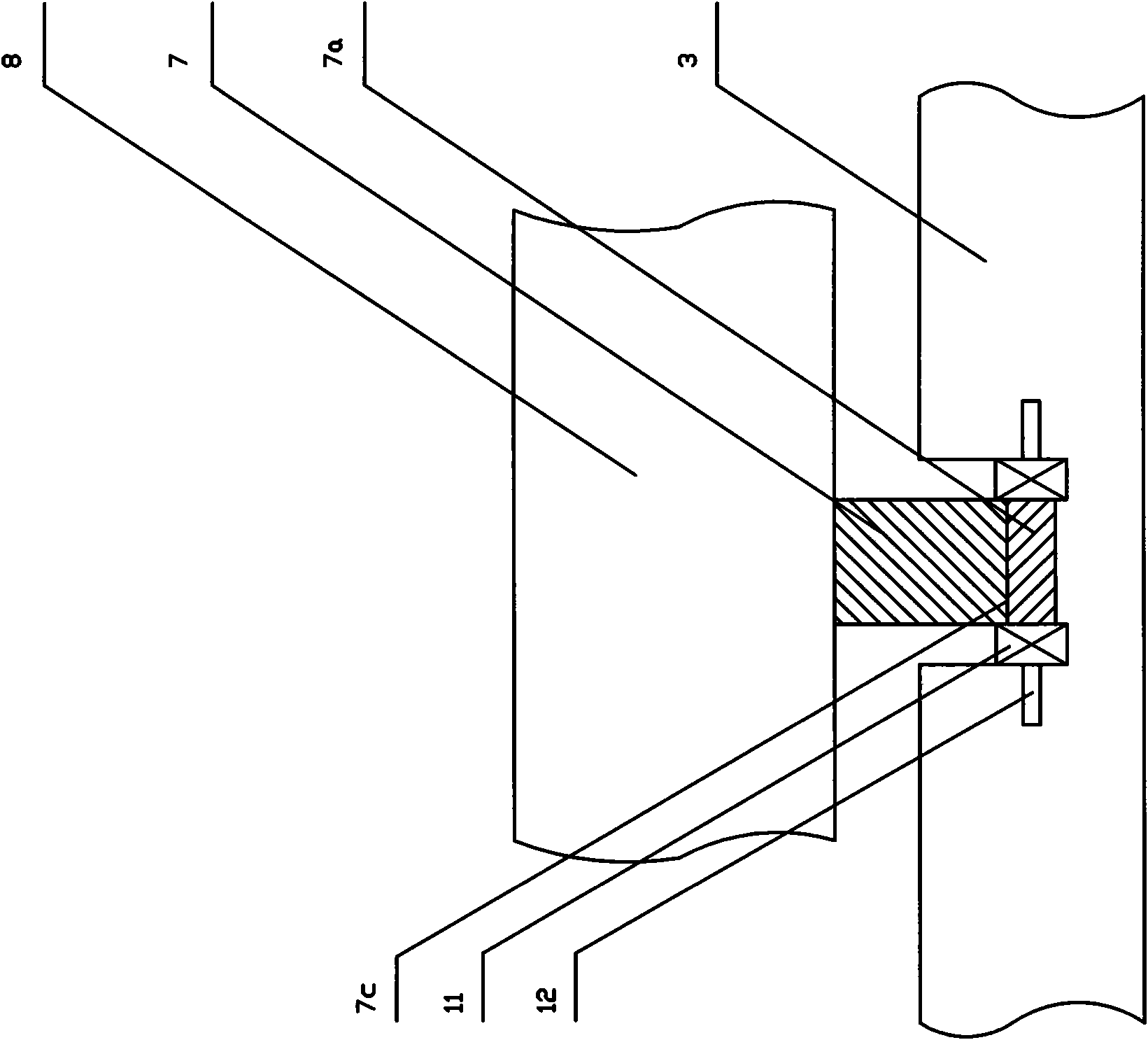

[0073] Such as figure 1 , figure 2 As shown, in the embodiment of the present invention, in a weighing method embodiment of a dynamic dump truck scale, the dump truck includes a weighing instrument 2 arranged on the front 1 to display valid weighing data, and the hinge is installed on the truck beam of the dump truck 3 The shaft pin sensor 7a at the tail, the pressure sensor 6a connected to the oil outlet pipeline 6c connected to the hydraulic support rod 6 installed on the dump truck beam 3, and the shaft pin sensor 7a connected to the shaft pin sensor 7a arranged on the vehicle body The pin sensor signal transmission line 7b transmits the effective weighing data to the weighing instrument 2; the pressure sensor 6a transmits the effective weighing data to the weighing instrument 2 through the pressure sensor signal transmission line 6b arranged on the vehicle body and connected to the pressure sensor 6a, The weight of the goods reflected by the processing unit of the weighi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com